Laser grooving device and method

A laser slotting and laser beam technology, which is applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve problems such as unstable dimensional accuracy, workpiece heating and melting, and microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

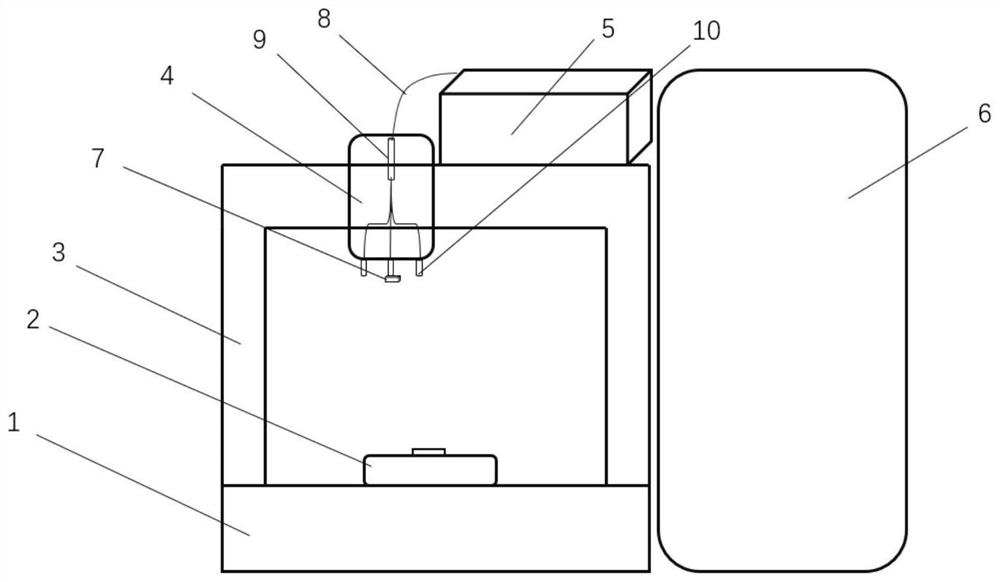

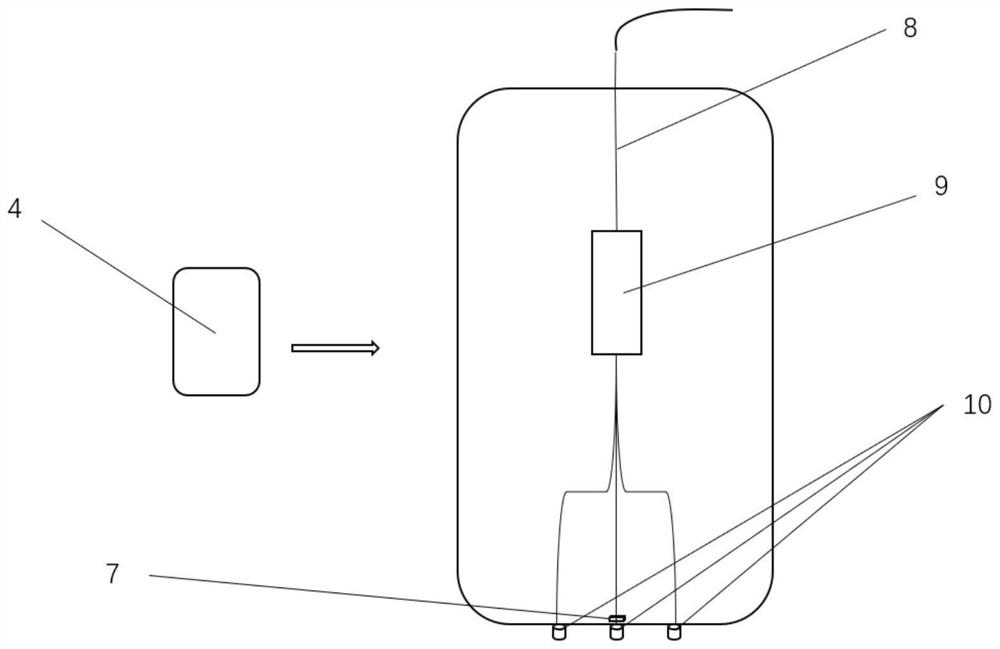

[0035] refer to figure 1 , shows a prior art laser grooving device. The laser grooving device includes a marble base 1 , a workpiece clamping unit 2 , a frame 3 , a laser optical path unit 4 , a laser 5 and a control unit 6 . The marble base 1 is used for horizontal positioning and vertical positioning, which is convenient for the control unit 6 to accurately control the spatial movement direction of the rack 3 and the laser optical path unit 4 . The workpiece clamping unit 2 is located on the marble base 1 and is used for fixing the workpiece 11 , while the workpiece clamping unit 2 can move horizontally relative to the marble base 1 . The frame 3 is fixed on the marble base 1, wherein the laser 5 and the laser optical path unit 4 are fixed on the frame 3, and the laser optical path unit 4 can move along the frame 3 in X (left and right) and Z (up and down) directions. The laser 5 generally adopts a pulsed laser, which can be a nanosecond, picosecond, or femtosecond laser. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com