HDPE double-layer steel belt hot melting sewage pipe material containing ardealite and preparation method thereof

A technology for phosphogypsum and sewage pipes, which is applied in the field of HDPE double-layer steel strip hot-melt sewage pipe materials and preparation, can solve the problems of cost reduction, environmental pollution, and low application rate of phosphogypsum, so as to reduce stockpiling and improve physical and mechanical Performance, the effect of increasing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

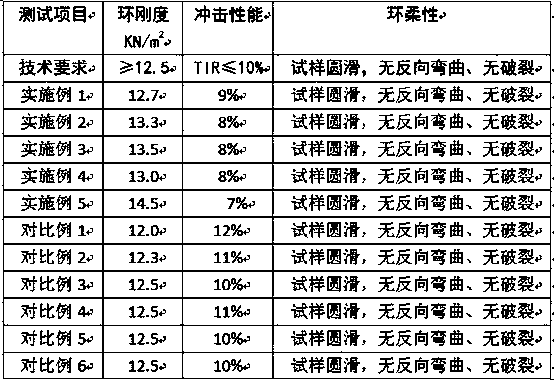

Examples

Embodiment 1

[0037] (1) Drying and cutting: Weigh 120kg of high-density polyethylene, 160kg of phosphogypsum with a particle size of 1200 mesh, 4kg of masterbatch, 9kg of defoamer, 0.5kg of stearic acid, 5kg of artemisia annua powder, 1kg of methylcellulose and 0.5kg epoxy resin, mix the raw materials evenly and dry, the suction device sucks the dried raw materials into the hopper, and discharges the material to the barrel of the extruder;

[0038] (2) Extrusion molding: set the temperature of the extruder to 200°C, the screw of the extruder cuts, extrudes, melts, and pre-plasticizes the raw material, and the raw material enters the mold to form a preliminary shape to obtain a pipe;

[0039] (3) Shaping cooling: the sizing sleeve accurately sizing the formed pipe, and the spray box sprays water on the pipe to cool and shape the pipe;

[0040] (4) Cutting and packaging: the tractor pulls the pipe obtained in step 3 to the cutting machine, and the cutting machine cuts the product according t...

Embodiment 2

[0042] (1) Drying and cutting: Weigh 160kg of high-density polyethylene, 160kg of phosphogypsum with a particle size of 1200 mesh, 5kg of masterbatch, 12kg of defoamer, 1.5kg of stearic acid, 8kg of artemisia annua powder, 3kg of methylcellulose and 1.5kg epoxy resin, mix the raw materials evenly and dry, the suction device sucks the dried raw materials into the hopper, and discharges the material to the barrel of the extruder;

[0043] (2) Extrusion molding: set the temperature of the extruder to 200°C, the screw of the extruder cuts, extrudes, melts, and pre-plasticizes the raw material, and the raw material enters the mold to form a preliminary shape to obtain a pipe;

[0044] (3) Shaping cooling: the sizing sleeve accurately sizing the formed pipe, and the spray box sprays water on the pipe to cool and shape the pipe;

[0045] (4) Cutting and packaging: the tractor pulls the pipe obtained in step 3 to the cutting machine, and the cutting machine cuts the product according ...

Embodiment 3

[0047] (1) Drying and cutting: Weigh 160kg of high-density polyethylene, 120kg of phosphogypsum with a particle size of 1200 mesh, 4kg of masterbatch, 9kg of defoamer, 0.5kg of stearic acid, 5kg of Artemisia annua powder, 1kg of methylcellulose and 0.5kg epoxy resin, mix the raw materials evenly and dry, the suction device sucks the dried raw materials into the hopper, and discharges the material to the barrel of the extruder;

[0048] (2) Extrusion molding: set the temperature of the extruder to 200°C, the screw of the extruder cuts, extrudes, melts, and pre-plasticizes the raw material, and the raw material enters the mold to form a preliminary shape to obtain a pipe;

[0049] (3) Shaping cooling: the sizing sleeve accurately sizing the formed pipe, and the spray box sprays water on the pipe to cool and shape the pipe;

[0050] (4) Cutting and packaging: the tractor pulls the pipe obtained in step 3 to the cutting machine, and the cutting machine cuts the product according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com