Driven wheel mechanism and vehicle

A driven wheel and wheel carrier technology, applied in power steering mechanisms, electric steering mechanisms, electric vehicles, etc., can solve problems such as poor braking experience and safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

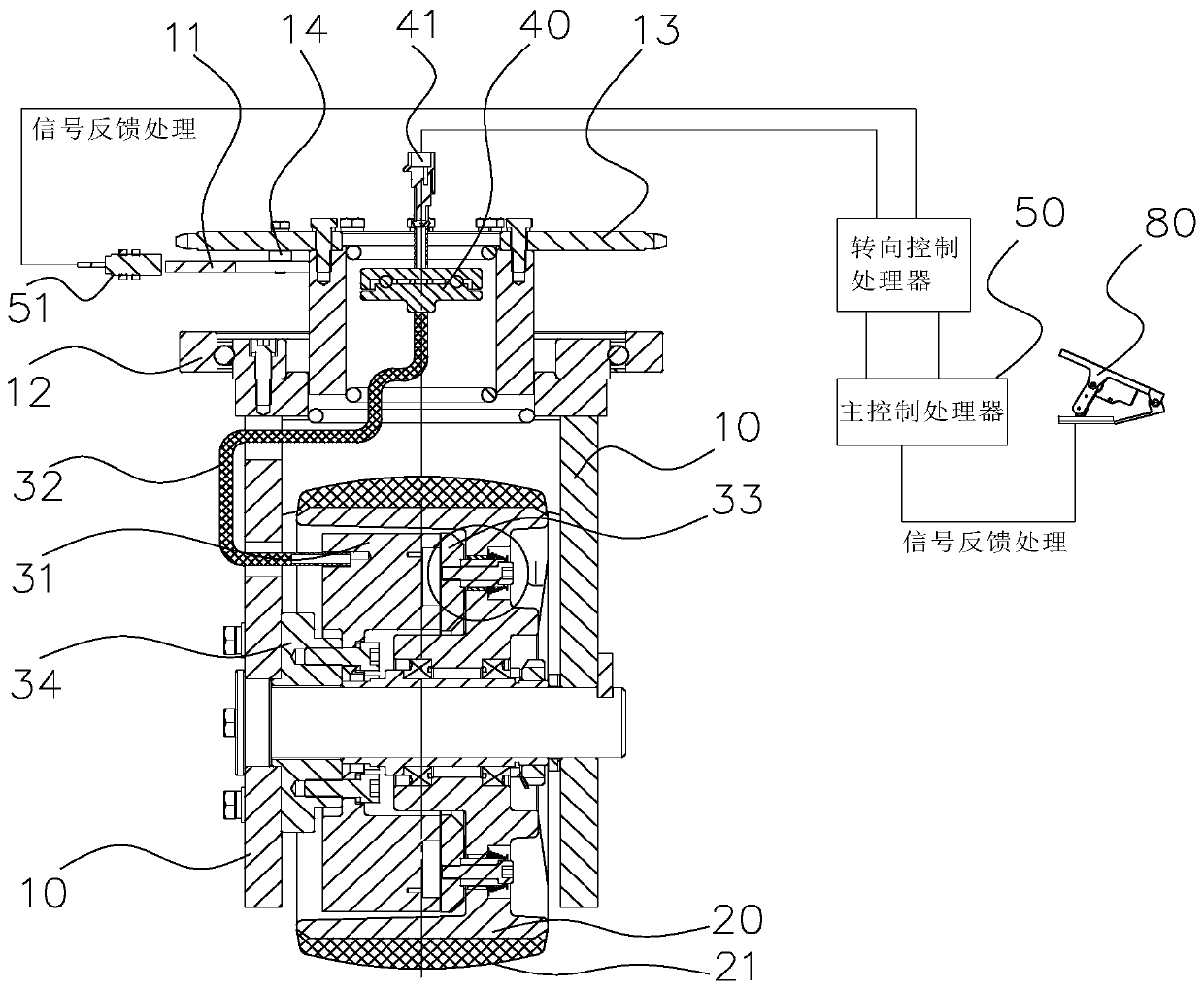

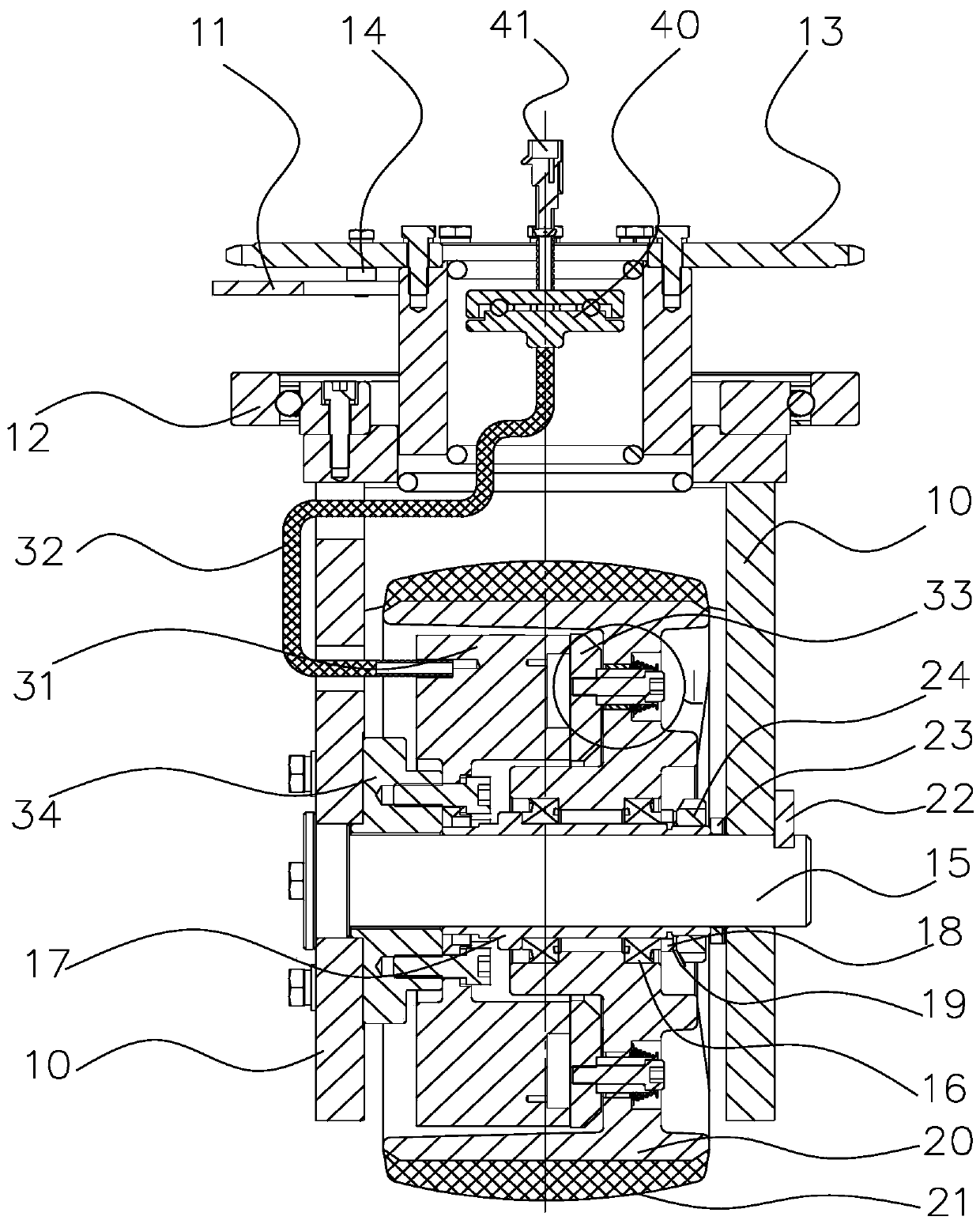

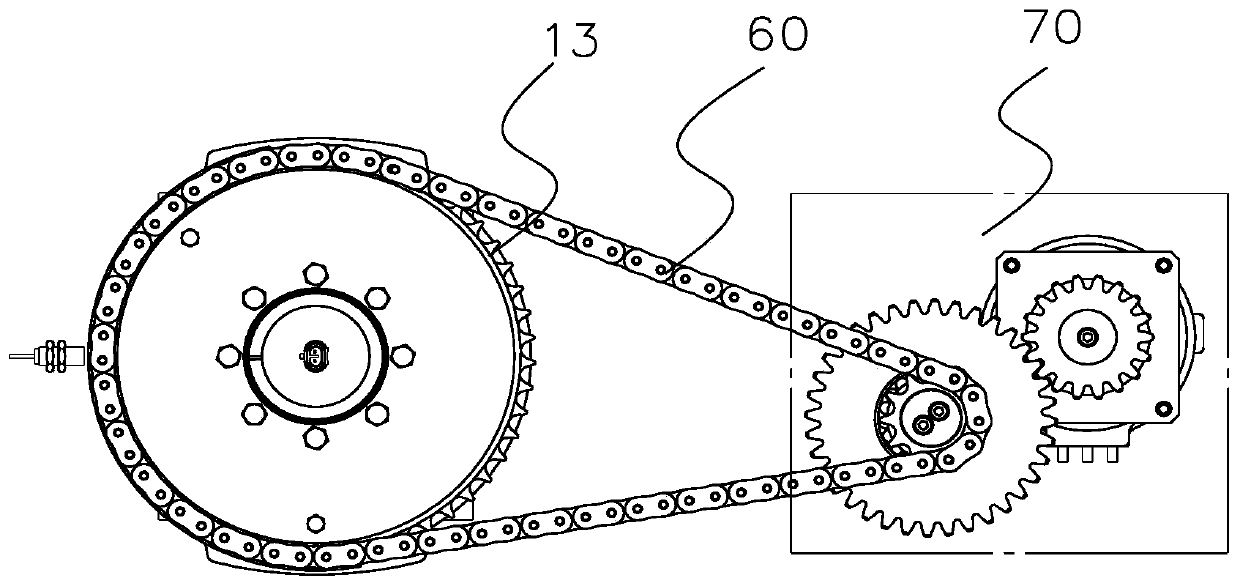

[0025] Such as figure 1 with figure 2 As shown, this embodiment provides a driven wheel mechanism, including a wheel frame 10, a wheel hub 20, an electromagnetic brake, a harness rotator 40, a steering motor and a main control processor 50, wherein the wheel hub 20 is arranged on the wheel frame 10 Between the internal gears, the rotation angle of the hub 20 is fed back to the main control processor 50 by the encoder on the steering motor, and the main control processor 50 calculates the steering angle of the hub 20 Angle and position control the movement of the hub 20, the electromagnetic brake and the wire harness rotator 40 are both arranged in the wheel frame 10, the electromagnetic brake includes a base 31, a wire harness 32 and a brake pad 33, The wire harness 32 passes through the wire harness rotator 40 and is connected to the base 31, the base 31 is connected to the wheel frame 10, and the base 31 and the brake pad 33 are provided with There is a first gap, the fir...

Embodiment 2

[0042] This embodiment provides a vehicle, which includes the driven wheel mechanism described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com