UHF resonator

A resonator and strip-shaped technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of increased energy loss, increased processing difficulty, and thin film manufacturing difficulties, and achieves good industrialization prospects, low processing difficulty, and high production efficiency. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

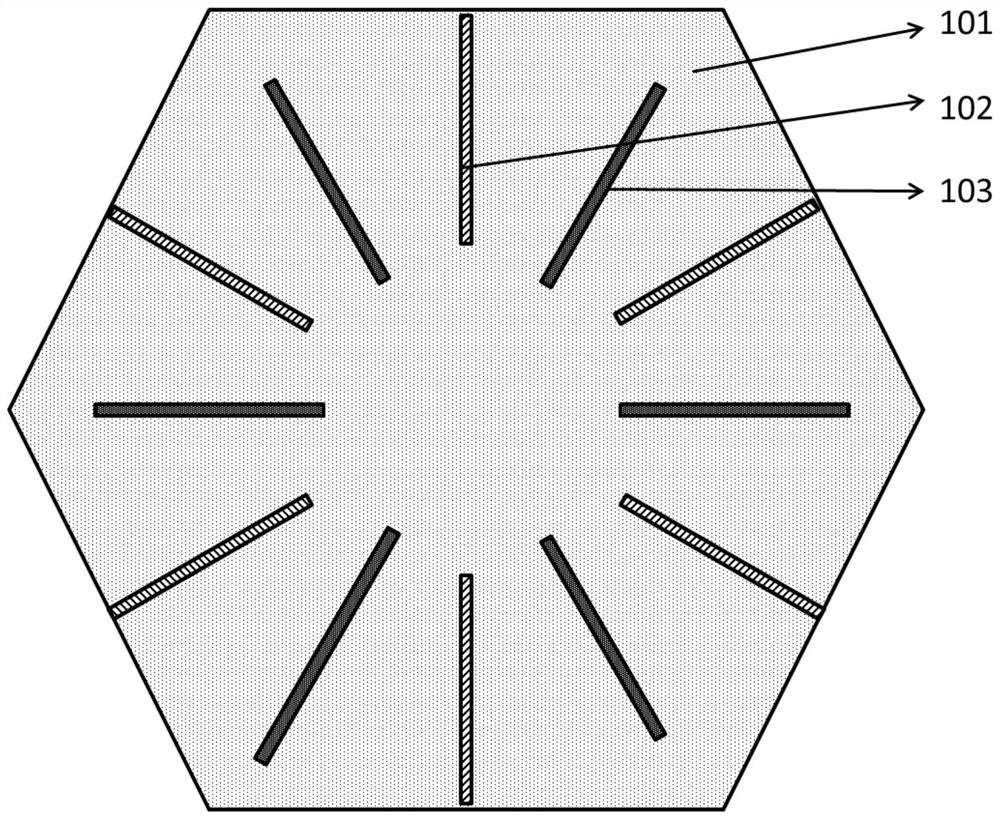

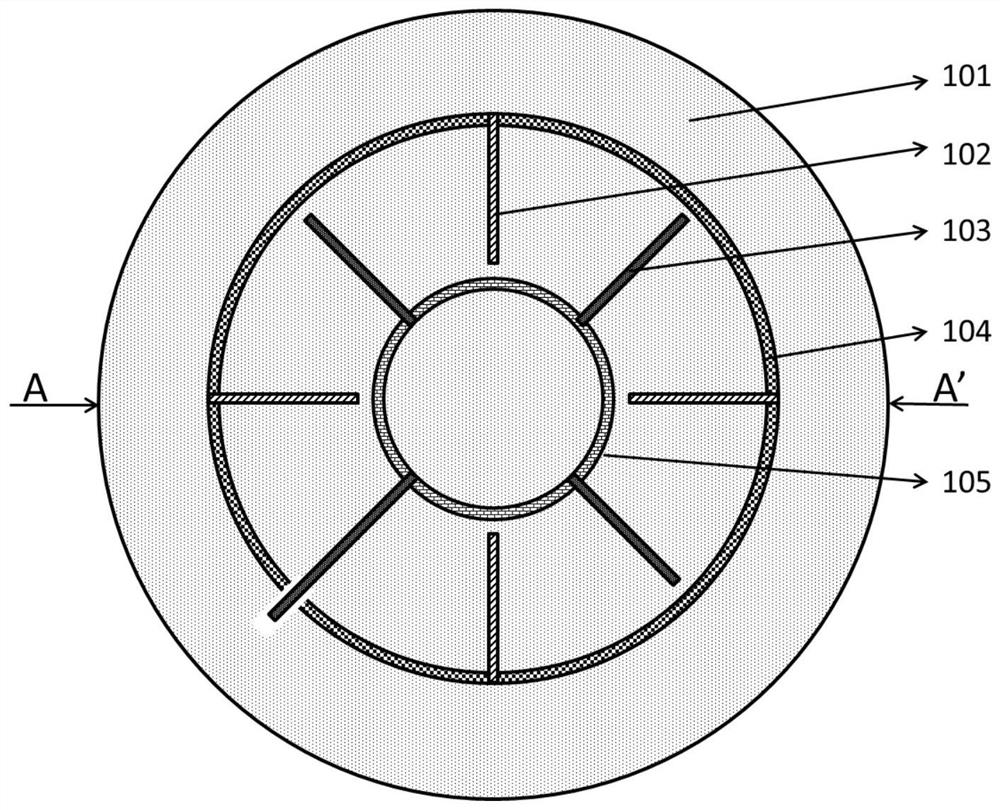

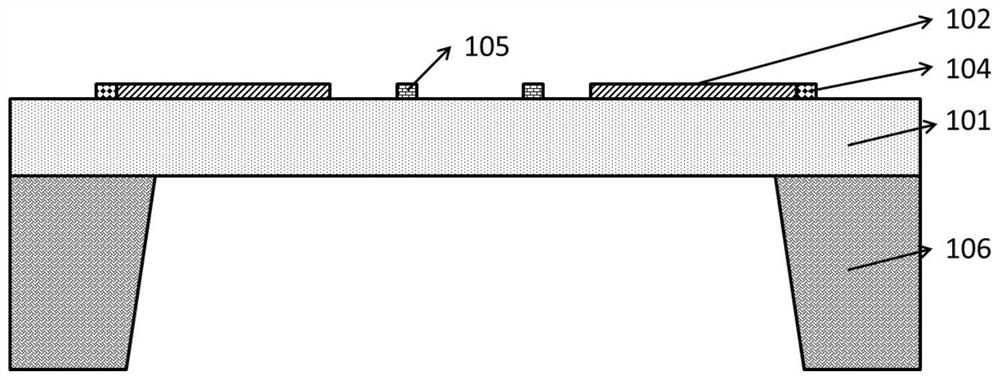

[0015] like Figure 1 ~ Figure 4 , the ultrahigh frequency resonator includes a piezoelectric layer 101 and a plurality of strip-shaped positive electrodes 102 and a plurality of strip-shaped negative electrodes 103 deposited on the piezoelectric layer 101 . like figure 1 , 2a , the piezoelectric layer 101 can be in regular or irregular shapes such as circles, pentagons, and hexagons. The material of the piezoelectric layer 101 can be thin film materials with piezoelectric properties such as lithium niobate, lithium tantalate, aluminum nitride, scandium-doped aluminum nitride and the like.

[0016] A plurality of strip-shaped positive electrodes 102 and a plurality of strip-shaped negative electrodes 103 are radially distributed on the piezoelectric layer 101 . And the strip-shaped positive electrodes 102 and the strip-shaped negative electrodes 103 are distributed alternately, that is, the strip-shaped negative electrodes 103 are distributed between the two strip-shaped po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com