Pretreatment assembly and method for treating work pieces

一种预处理、组件的技术,应用在预处理表面、电气元件、运输和包装等方向,能够解决设备磨损、起停运动缓慢、撕扯等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

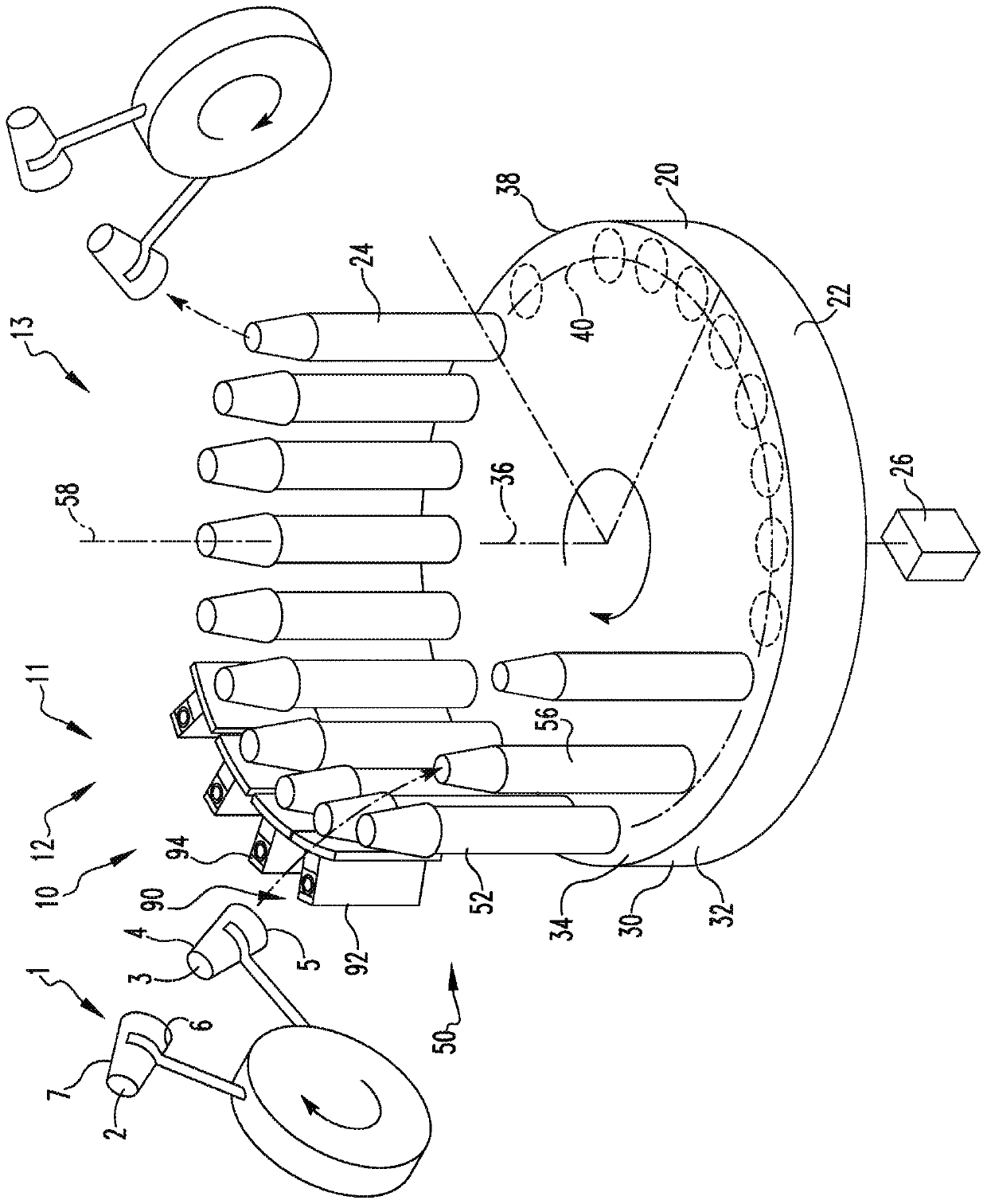

[0016] It is to be understood that certain elements shown in the drawings herein and described in the following specification are exemplary embodiments of the disclosed concepts only, offered as non-limiting examples for purposes of illustration only. Thus, specific dimensions, orientations, assemblies, quantities, embodiment configurations and other physical characteristics of parts used in connection with the embodiments disclosed herein are not to be construed as limiting the scope of the disclosed concepts.

[0017] Directional phrases such as, for example, clockwise, counterclockwise, left, right, top, bottom, up, down, and their derivatives as used herein relate to the orientation of elements shown in the drawings and do not limit the claims. , unless explicitly stated otherwise in this document.

[0018] As used herein, the singular forms "a", "an" and "the" include plural references unless the context clearly dictates otherwise.

[0019] As used herein, "constructed [...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com