A kind of laundry detergent and its preparation system and preparation process

A preparation system and laundry detergent technology, applied in liquid degassing, liquid degassing through vibration, separation methods, etc., can solve problems such as incomplete defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

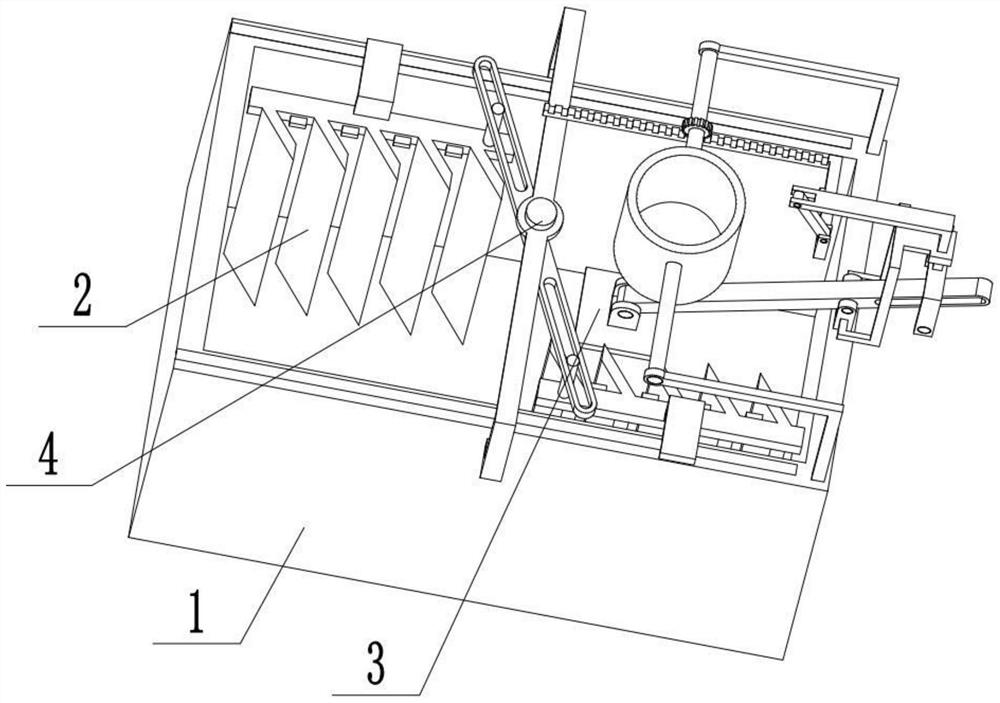

[0030] Combine below Figure 1-7Illustrating this embodiment, a laundry liquid preparation system includes a stirring box 1 , a stirring assembly 2 , a defoaming agent control mechanism 3 and a defoaming agent pouring mechanism 4 , and the stirring assembly 2 is cooperatively connected in the stirring box 1 . , the stirring assembly 2 drives the washing liquid in the stirring box 1 to stir and mix evenly, the defoaming agent control mechanism 3 and the defoaming agent pouring mechanism 4 are both arranged on the stirring box 1, and the defoaming agent control mechanism 3 and the defoaming agent are poured The mechanism 4 is matched and connected, and the defoaming agent control mechanism 3 is used to drive the defoaming agent pouring mechanism 4 to pour the defoaming agent into the stirring box 1 . When in use, put the laundry liquid to be processed into the stirring box 1, pour a sufficient amount of defoamer into the antifoaming agent pouring mechanism 4, and start the stirr...

specific Embodiment approach 2

[0031] Combine below Figure 1-7 Illustrating this embodiment, the lower end of the stirring box 1 is fixedly connected and communicated with a drain pipe 1-1 with a control valve. The upper end of the stirring box 1 is symmetrically provided with two trapezoidal slide rails 1-2. The stirring assembly 2 Connect with the two trapezoidal slide rails 1-2. The processed laundry liquid is discharged through the control drain pipe 1-1.

specific Embodiment approach 3

[0032] Combine below Figure 1-7 Illustrating this embodiment, the stirring assembly 2 includes a driving motor 2-1, a motor frame 2-2, a double-slotted rod 2-3, a lever 2-4, a stirring plate fixing frame 2-5, and an L-shaped sliding seat 2 -6. The stirring plate 2-7 and the ultrasonic generator 2-8; the driving motor 2-1 is fixedly connected to the motor frame 2-2, the motor frame 2-2 is fixedly connected to the upper end of the stirring box 1, and the driving motor 2- The output shaft of 1 is fixedly connected to the double-slotted rod 2-3, the two levers 2-4 are respectively connected to the two ends of the double-slotted lever 2-3 by sliding fit, and the two levers 2-4 are fixedly connected to the two stirring plates respectively. On the fixing frame 2-5, the upper ends of the two stirring plate fixing frames 2-5 are respectively fixedly connected to an L-shaped sliding seat 2-6, and the two L-shaped sliding seats 2-6 are respectively connected to the two trapezoidal slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com