Aircraft three-axis attitude control system and method based on active flow control

A technology of active flow control and three-axis attitude, applied in attitude control, control/adjustment system, non-electric variable control, etc., can solve problems such as poor reliability, difficulty in providing sufficient control torque, and reduced flight performance, and achieve fast response speed , Improve maneuverability and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

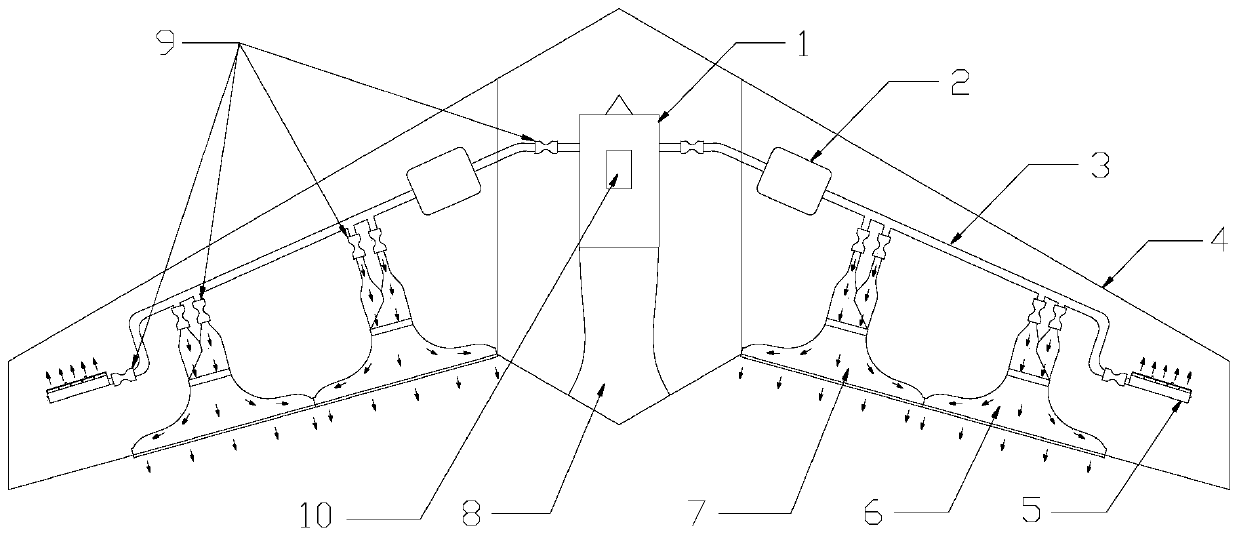

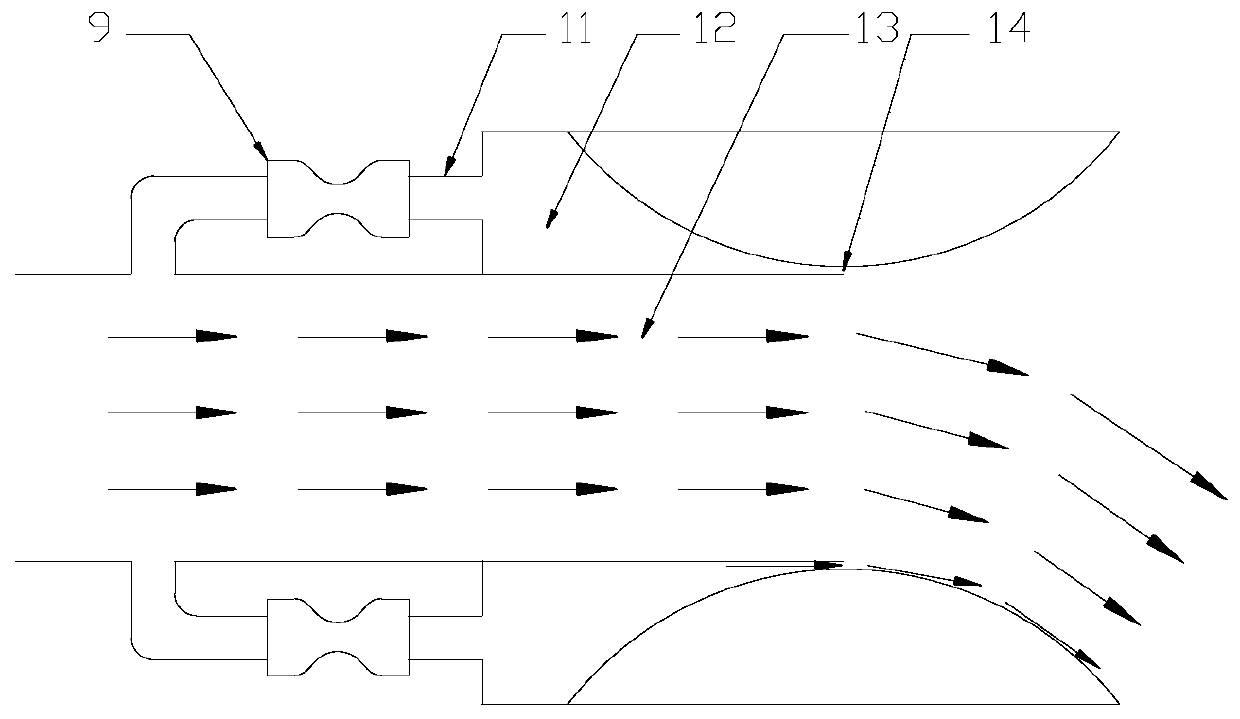

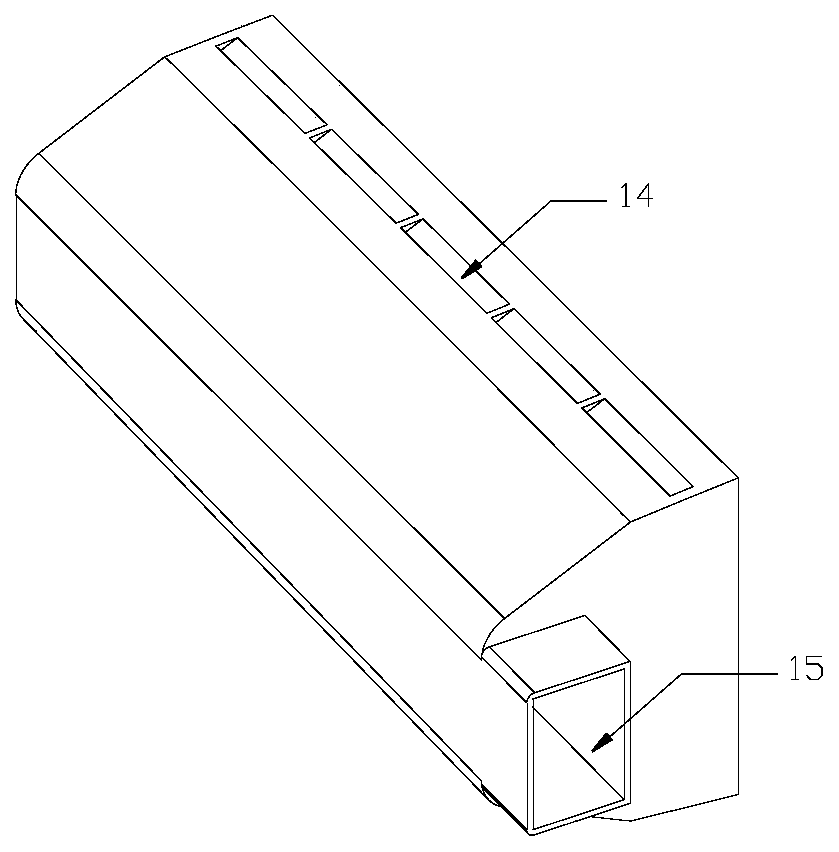

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] like figure 1 As shown, the aircraft three-axis attitude control system based on active flow control includes a flying wing layout body 4, an engine 1, a high-pressure gas storage cylinder 2, a bleed air pipeline 3, a jet thrust vectoring device 8 at the rear of the fuselage, and a wing rear Edge roll circulation control actuator 6, pitch circulation control actuator 7, wing tip reverse blowing actuator 5, electromagnetic proportional valve 9, flight attitude control module 10, roll circulation control actuator 6 , the pitching circulation control exciter 7, and the reverse blowing exciter 5 are connected with the high-pressure gas storage cylinder through pipelines and lead air from the high-pressure gas storage cylinder, and each exciter is provided with a Electromagnetic proportional valve, when the invention is in operation, the high-pressure gas cylinder i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap