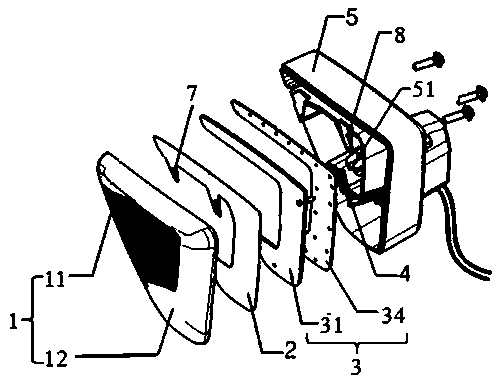

Light-emitting sign with light-transmitting function and manufacturing method of light-emitting signboard

A manufacturing method and technology of signs, which are applied in the directions of illuminated signs, instruments, display devices, etc., can solve the problem that metal luminous signs cannot achieve high uniformity and no chromatic aberration lighting effect, etc., so as to improve the utilization rate of light energy and reduce the Heat dissipation burden and the effect of improving light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0053] Example 1:

[0054] The nano-scale metal plating layer is coated on the inner surface of the transparent component 12.

Example Embodiment

[0055] Example 2:

[0056] Such as Figure 5 As shown, the surface light source module optical panel 31 includes a bottom optical structure layer 311 and an upper optical structure layer 312. The bottom optical structure layer 311 is a reflective microstructure, and the structural characteristics of its bumps can project the light beam to the bottom layer. Reflected out, thereby improving the utilization of light efficiency. Since the light beam emitted by the LED light source has a Gaussian distribution, bright spots will be generated at the center of the beam, thereby reducing the overall uniformity. The upper optical structure layer 312 includes optically uniform microstructures and bright spot shielding Therefore, the upper optical structure layer 312 on the upper surface of the optical panel 31 of the surface light source module can achieve the effect of hiding the bright spots of the light spot, thereby making the light distribution more uniform.

Example Embodiment

[0057] Example 3:

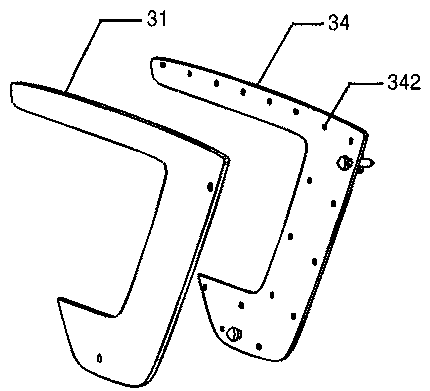

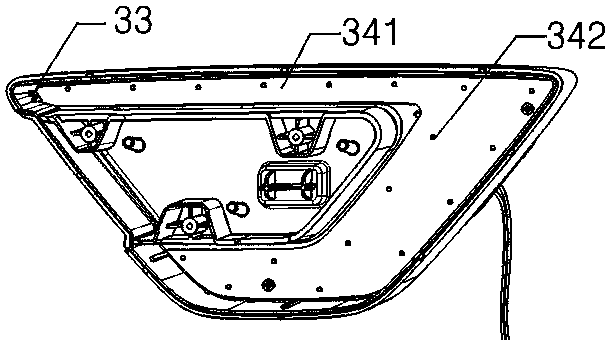

[0058] Such as Image 6 As shown, the optical system 3 includes a reflective bowl 35 and a circuit board 34, the reflective bowl 35 is arranged in an array, the focal length of the reflective bowl 35 is between 3mm-4mm, the spacing is 20mm-26mm, and the height of the reflective bowl 35 is 10mm-18mm. The distance from the diffuser 2 is greater than 10 mm.

[0059] A method for manufacturing the light-emitting sign with the light-transmitting function, the nano-level metal coating is realized by the PVD vacuum sputtering coating method, and the light transmittance is controlled between 10%-20% by adjusting the thickness of the nano-level metal coating .

[0060] In this embodiment, the reflection coefficient of the light-transmitting component 12 is 80%, the light transmission coefficient is 15%, the absorption coefficient is 5%, and the tolerance is ±5%.

[0061] In this embodiment, the reflection coefficient of the diffuser 2 is 25%, the light transmission coeffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap