High-thermal-conductivity water-based damping coating and preparation method thereof

A damping coating, hot water technology, applied in anti-corrosion coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve the problems of reduced mechanical life, high temperature, and the temperature of mechanical parts cannot be well dissipated, and achieve high composite loss. Factors, excellent performance, and simple production equipment and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

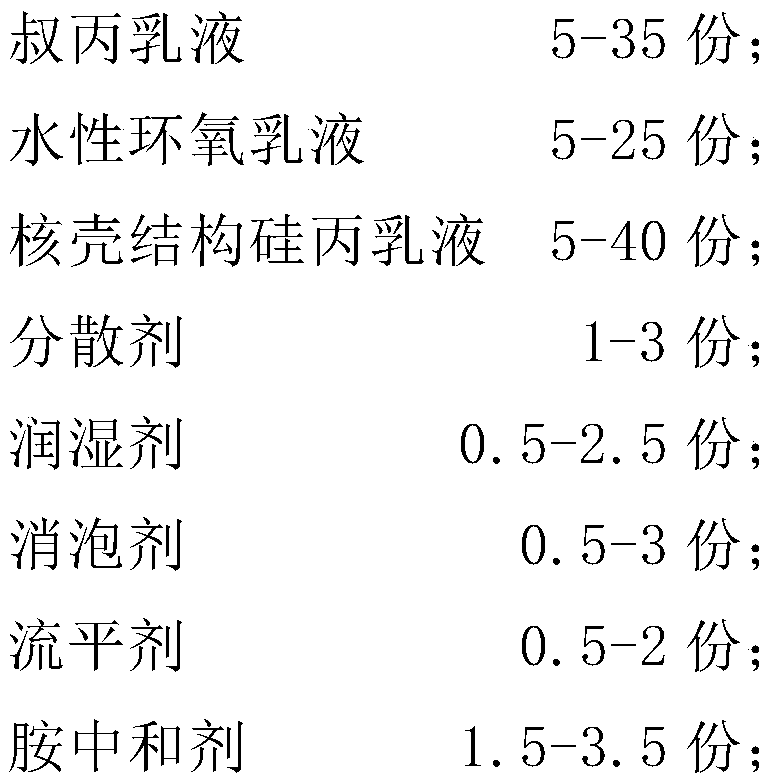

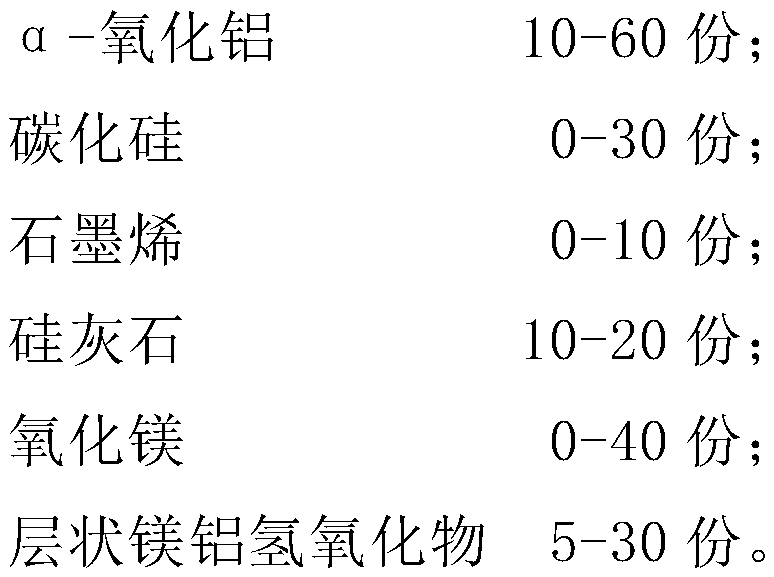

[0036] A high thermal conductivity damping coating of this embodiment, the main components are proportioned according to the following mass ratio: 10 parts of tertiary acrylic emulsion; 10 parts of water-based epoxy emulsion; 10 parts of silicon acrylic emulsion; 30 parts of α-alumina; silicon carbide 10 parts; 5 parts of graphene; 5 parts of wollastonite; 5 parts of magnesium oxide; 5 parts of layered magnesium aluminum hydroxide.

[0037] The method for preparing a kind of highly conductive water-based damping coating of this embodiment comprises the following steps:

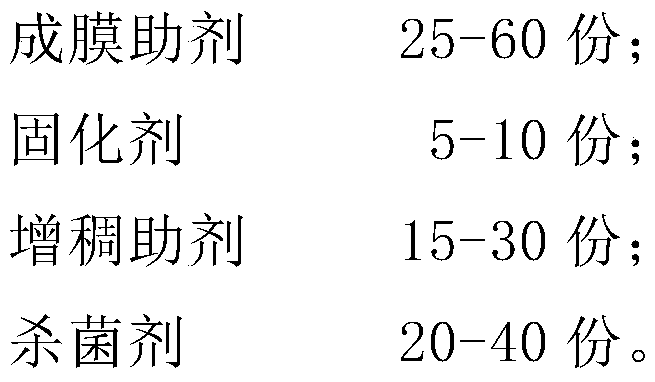

[0038] Step 1. Mix tert-acrylic emulsion, water-based epoxy emulsion, silicon-acrylic emulsion, 1 part of dispersant, 1.5 parts of wetting agent, 1.5 parts of defoamer, 0.5 parts of leveling agent, 1.5 parts of amine neutralizer and 10 parts of distilled water According to the above ratio, add in order under stirring at 300r / min, and stir at this speed for 20min after the addition to obtain a mixed solution; ...

Embodiment 2

[0043] A kind of highly conductive water-based damping coating of this embodiment, the main components are proportioned according to the following mass ratio: 5 parts of tertiary acrylic emulsion; 20 parts of water-based epoxy emulsion; 10 parts of silicon acrylic emulsion; 20 parts of α-alumina; graphene 5 parts; 5 parts of wollastonite; 5 parts of magnesium oxide; 15 parts of layered magnesium aluminum hydroxide.

[0044] The method for preparing a kind of highly conductive water-based damping coating of this embodiment comprises the following steps:

[0045] Step 1. Mix tert-acrylic emulsion, water-based epoxy emulsion, silicon-acrylic emulsion, 1.5 parts of dispersant, 0.5 parts of wetting agent, 2.5 parts of defoamer, 1 part of leveling agent, 2 parts of amine neutralizer and 14 parts of distilled water According to the above ratio, add in order under stirring at 500r / min, and stir at this speed for 25min after the addition to obtain a mixed solution;

[0046] Step 2. Ad...

Embodiment 3

[0050] A high-conductivity water-based damping coating of this embodiment, the main components are proportioned according to the following mass ratios: 20 parts of tertiary acrylic emulsion; 5 parts of water-based epoxy emulsion; 10 parts of silicon acrylic emulsion; 15 parts of α-alumina; silicon carbide 20 parts; 2 parts of graphene; 10 parts of wollastonite; 3 parts of magnesium oxide; 13 parts of layered magnesium aluminum hydroxide.

[0051]The method for preparing a kind of highly conductive water-based damping coating of this embodiment comprises the following steps:

[0052] Step 1. Mix tert-acrylic emulsion, water-based epoxy emulsion, silicon acrylic emulsion, 3 parts of dispersant, 2 parts of wetting agent, 2 parts of defoamer, 2.5 parts of leveling agent, 0.5 parts of amine neutralizer and 30 parts of distilled water According to the above ratio, add in order under stirring at 350r / min, and stir at this speed for 30min after the addition to obtain a mixed solution;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com