Method for synthesizing ethylbenzene from benzene and ethanol

A technology for synthesizing ethylbenzene and ethanol, applied in chemical instruments and methods, condensation between hydrocarbons and non-hydrocarbons to produce hydrocarbons, carbon compound catalysts, etc., can solve the problems of high by-product xylene content and low ethylbenzene selectivity, etc. Achieve the effect of less product impurities, low xylene content and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0069] The synthesis of embodiment 1-8 pure phase ZSM-11 molecular sieve

[0070] 1.4g sodium hydroxide is dissolved in 100g deionized water, and 50g silica sol (SiO 2 content 30%), 2.66g aluminum chloride and 2.33g aniline were mixed together and added to the above solution, crystallized at 180°C for 24h, after cooling, filtered, washed, and dried to obtain a pure phase ZSM-11 molecular sieve sample, which was recorded as sample 1#.

[0071] The operation steps are as above, and the type and ratio of raw materials and crystallization conditions are changed to obtain the ZSM-11 molecular sieve as follows.

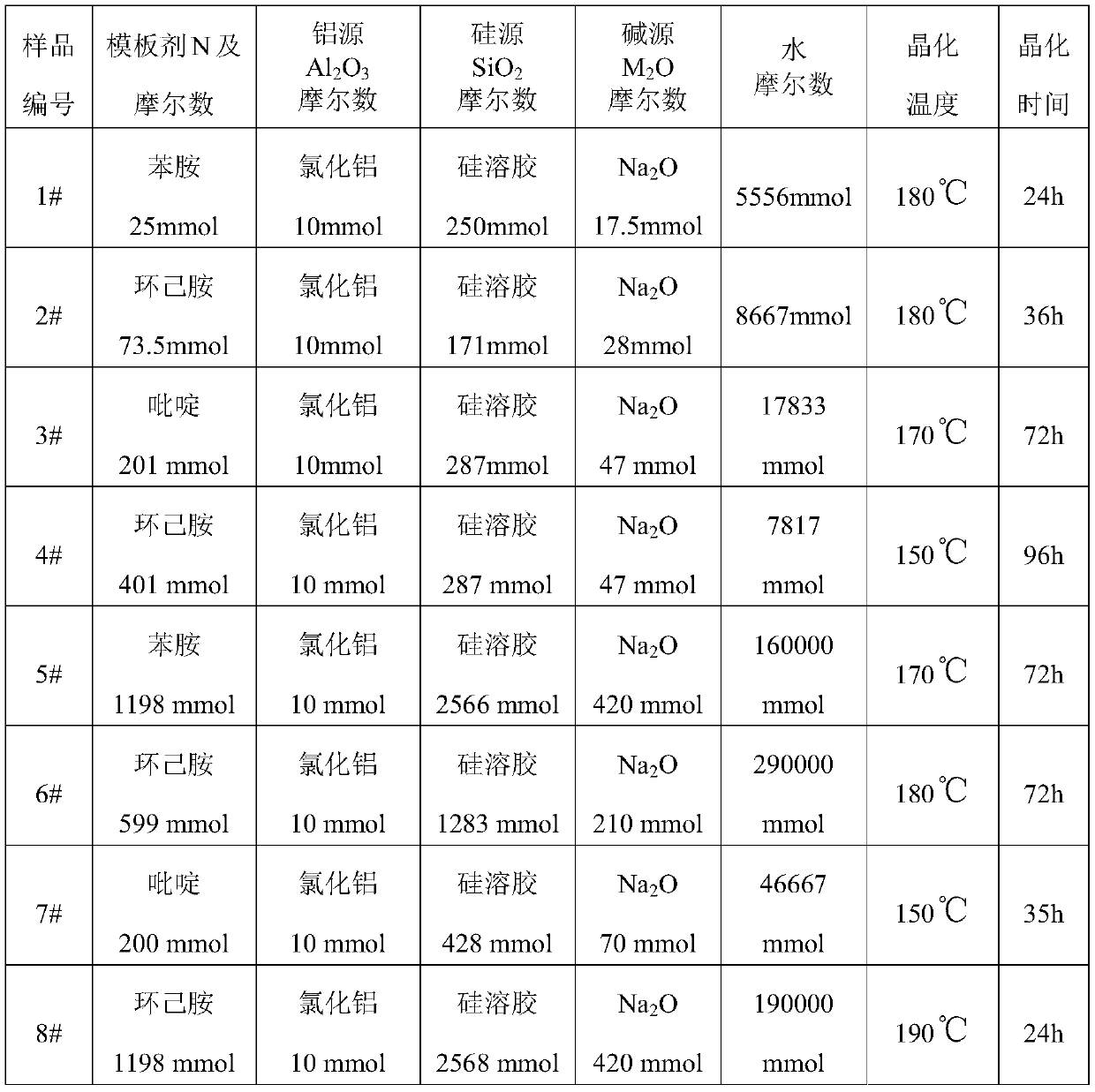

[0072] ZSM-11 molecular sieves synthesized under different conditions in table 1

[0073]

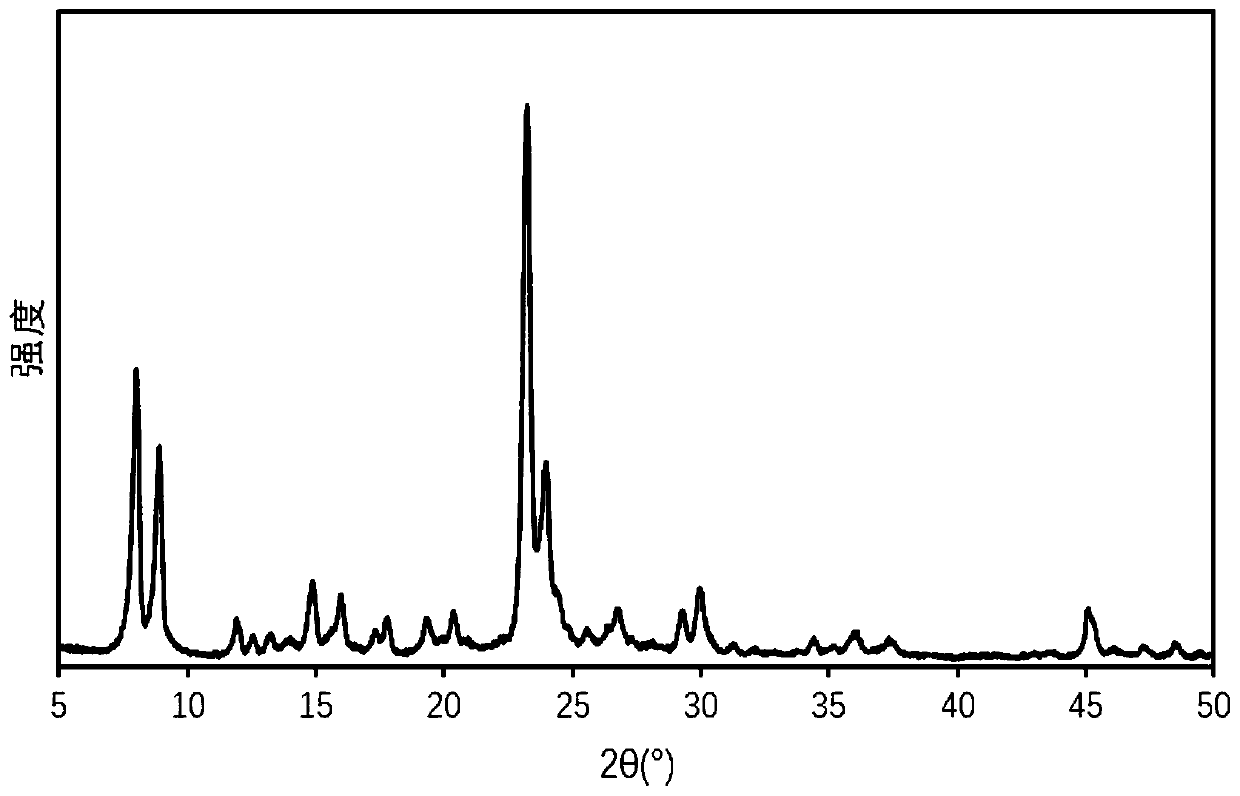

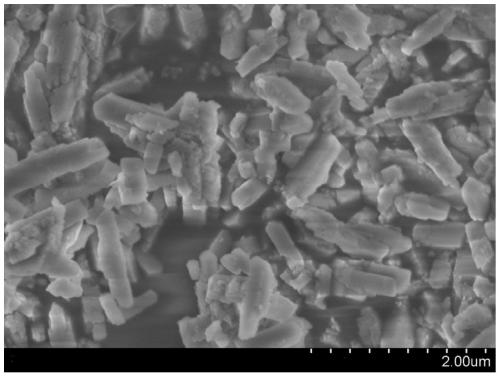

[0074] The XRD diffraction pattern of sample 1# is as follows figure 1 As shown, it can be seen that sample 1# is a single peak at 2θ=45.12°, which is the main difference from ZSM-5 and other heterogeneous phases. It can be seen that sample 1# is a pure phase ZSM-11. figure 2...

Embodiment 9-17

[0077] The raw materials benzene and ethanol are mixed uniformly in the liquid state in advance according to the molar ratio of 6:1 (6 mol of benzene, 1 mol of ethanol, 7 mol in total), and enter into the pure phase ZSM-11 molecular sieve catalyst synthesized by the above examples after being heated and vaporized. Alkylation reactor, the catalyst is 2# sample, the dosage is 1g, the bed temperature of the alkylation reactor is 440°C, the pressure is 1.2MPa, and the total weight space velocity is 5 hours -1 . Change the corresponding operating conditions, wherein the amount of ethanol is 1mol, and the amount of catalyst is 1g, see Table 2 for details.

[0078] Table 2 Alkylation reaction data of benzene and ethanol

[0079]

[0080] As can be seen from Table 2, using pure phase ZSM-11 as a catalyst, ethanol instead of ethylene as a raw material and benzene to synthesize ethylbenzene, the raw material cost is low, and the conversion rate is high; the product ethylbenzene has ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap