Electrode assembly

An electrode assembly and positive electrode technology, which is applied in the field of electrode assemblies, can solve the problems of increased internal resistance, accelerated electrode deterioration, thickness difference, etc., and achieves the effect of solving the increased internal resistance and electrode deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

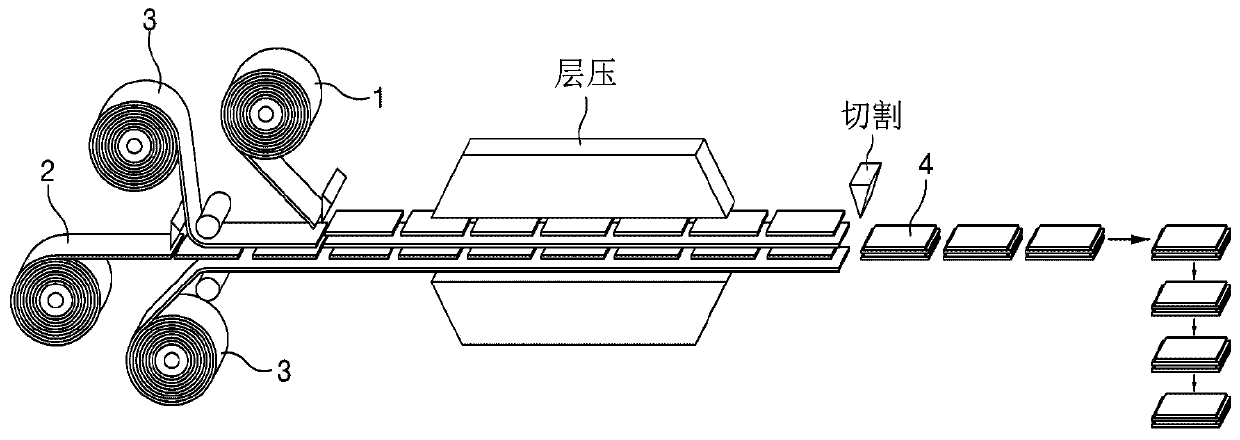

Method used

Image

Examples

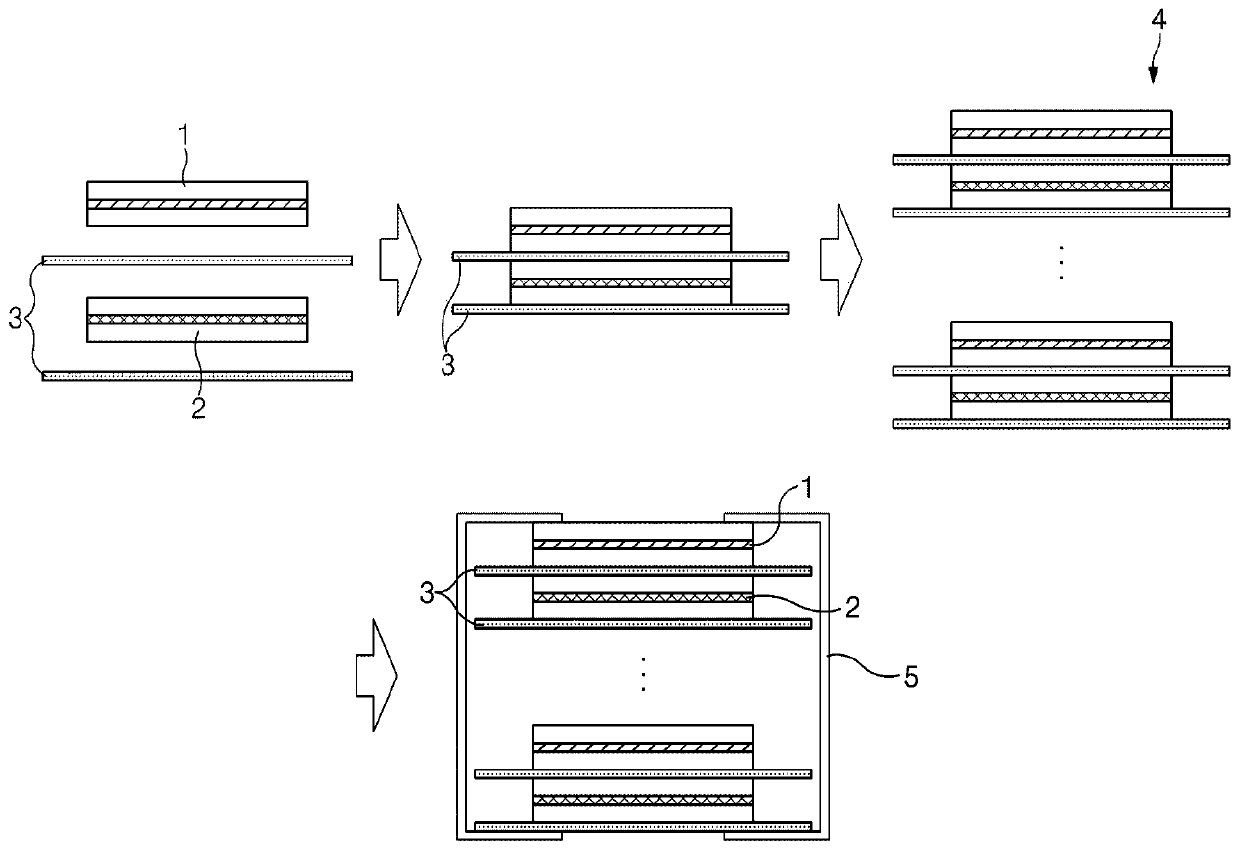

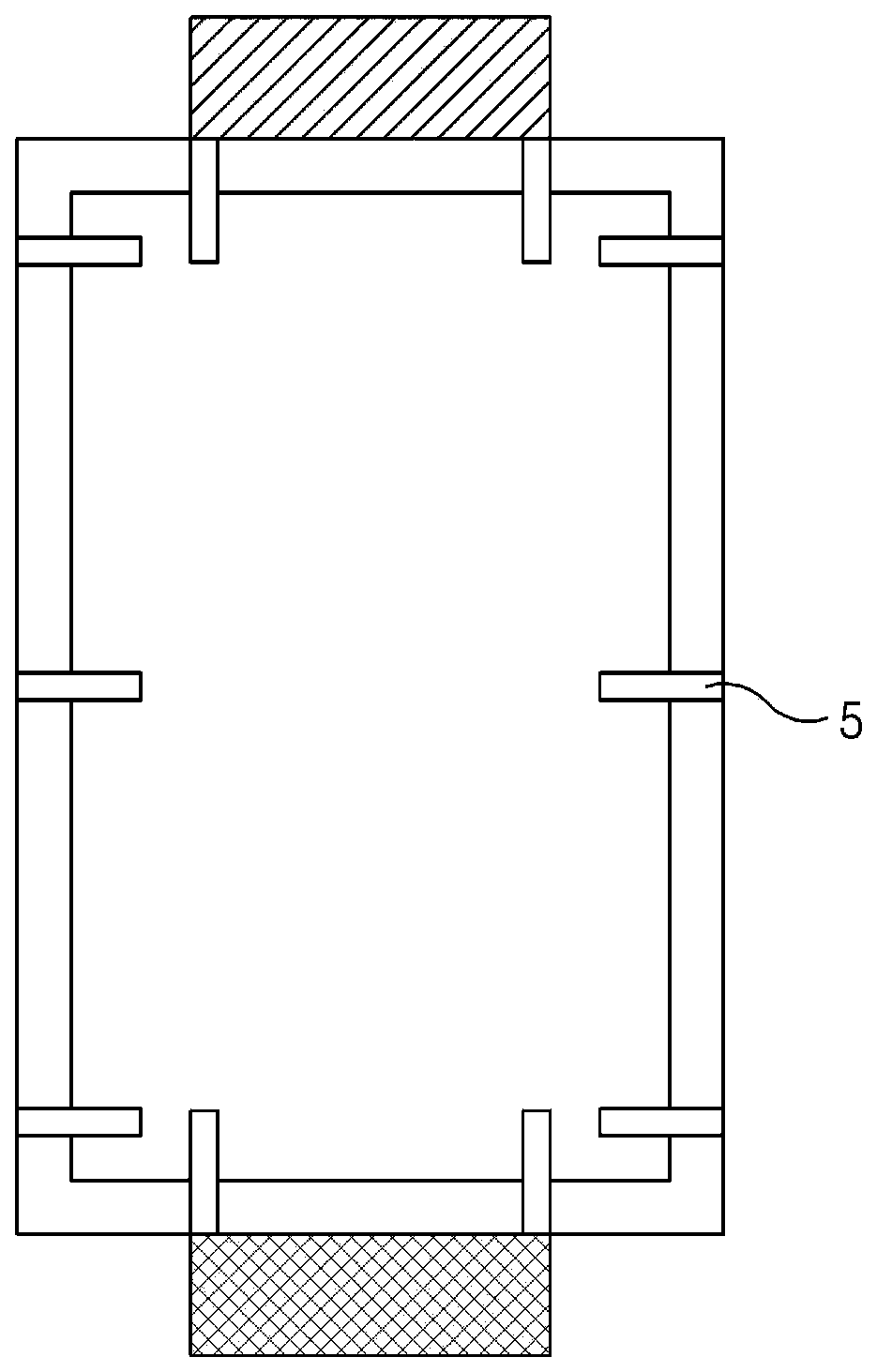

Embodiment approach 1

[0070] Figure 3a is a side view illustrating a state in which a plurality of single cells 100 and 101 are laminated according to Embodiment 1, in which figure 2 The single cells 100 are laminated at the uppermost layer, and the diaphragm extension 31 of the uppermost single cell 100 surrounds the entire single cells 100 and 101, and Figure 3b It is a plan view when the state of FIG. 3 is viewed downward from the upper side. Such as Figure 3a and Figure 3b As exemplified in , the electrode assembly according to Embodiment Mode 1 of the present invention is manufactured by laminating a plurality of single cells 100 and 101 . In the remaining single cells 101 except the uppermost single cell 100, the positive electrode 10, the separator 30, the negative electrode 20, and the separator 30 are sequentially laminated from the upper side downward, and each of the contact surfaces to be bonded to each other may be provided. Apply heat and / or pressure. However, the single cel...

Embodiment approach 2

[0078] In the electrode assembly, it is preferable not to provide double-sided positive electrodes in the outermost layer in order to minimize precipitation of lithium (Li) contained in the positive electrode active material. In more detail, a single-sided positive electrode or negative electrode may be provided on the outermost layer to prevent the positive electrode active material from being exposed from the outermost layer. Therefore, in the present invention, as Embodiment 2, a configuration in which a one-sided positive electrode is provided at the outermost layer is provided, and as Embodiment 3, a configuration in which the negative electrode 20 is provided at the outermost layer is provided.

[0079] That is, like the electrode assembly according to Embodiment 1, in the electrode assembly according to Embodiment 2, the single cell 100 including the separator 30 on which the expanded portion 31 is formed is laminated on the uppermost layer, and the positive electrode 10...

Embodiment approach 3

[0081] In the electrode assembly according to Embodiment 3 of the present invention, the negative electrode 20 is additionally laminated in the electrode assembly according to Embodiment 1 so that the negative electrode 20 is disposed on the uppermost layer.

[0082] which is, Figure 3c is a side view illustrating a state in which a plurality of single cells 100 and 101 are laminated according to Embodiment 3 of the present invention, wherein figure 2 The single cells 100 of 2 are laminated at the uppermost layer, and the separator extension 31 of the uppermost single cell 100 surrounds the entire cells 100 and 101 , and then the negative electrode 20 is additionally laminated on the separator extension. As illustrated in the drawing, the electrode assembly according to Embodiment 3 has a structure in which the end of the expanded portion 31 of the separator 30 surrounds and covers the entire uppermost positive electrode 10 in the structure according to Embodiment 1. Referri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com