Variable pitch impeller and wind driven generator

A blade and pitch technology, applied in wind turbines, wind turbine combinations, wind turbines in the same direction as the wind, etc., can solve problems such as low efficiency, large blade resistance, and inconvenient transportation, and achieve improved efficiency, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

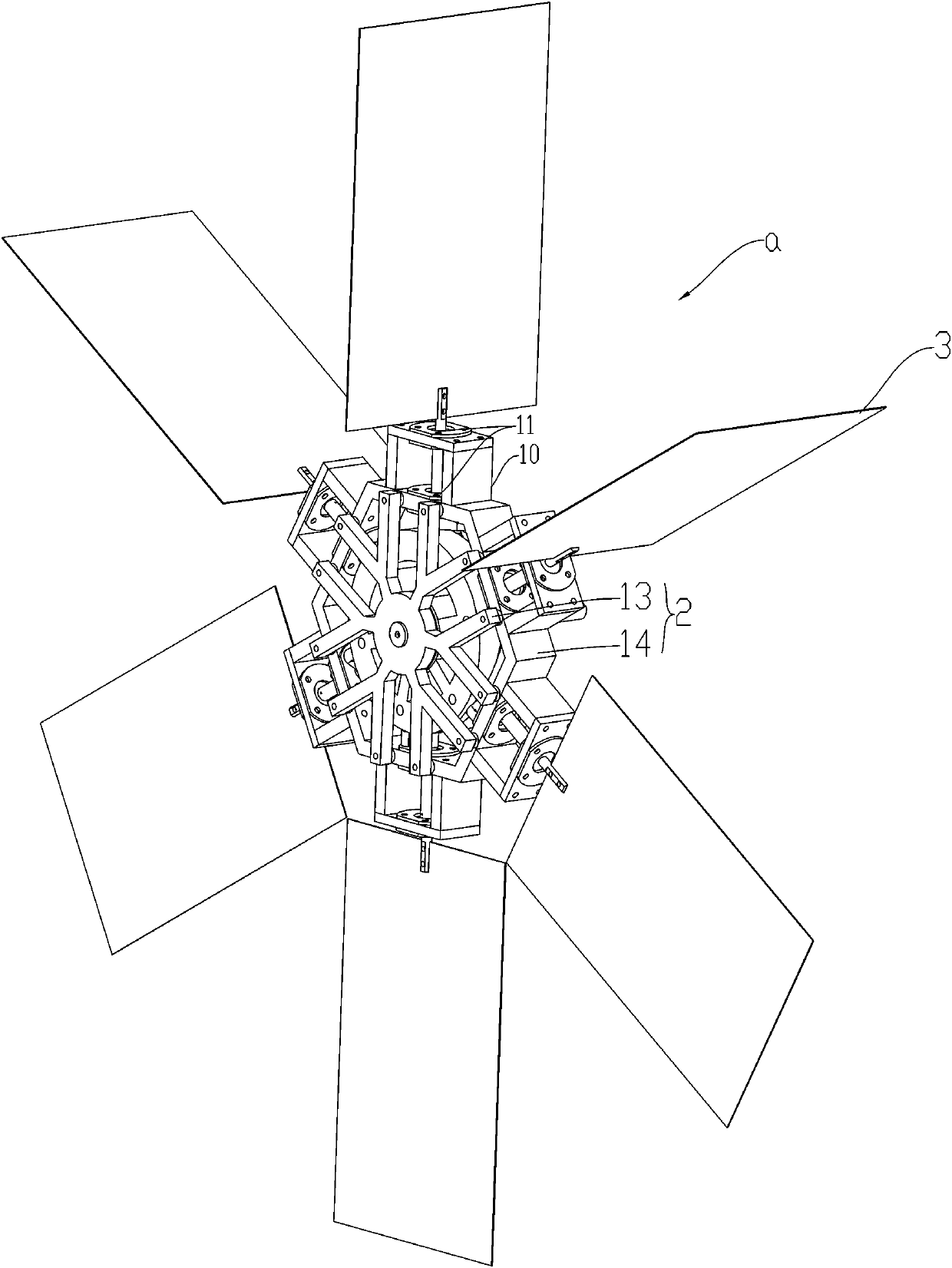

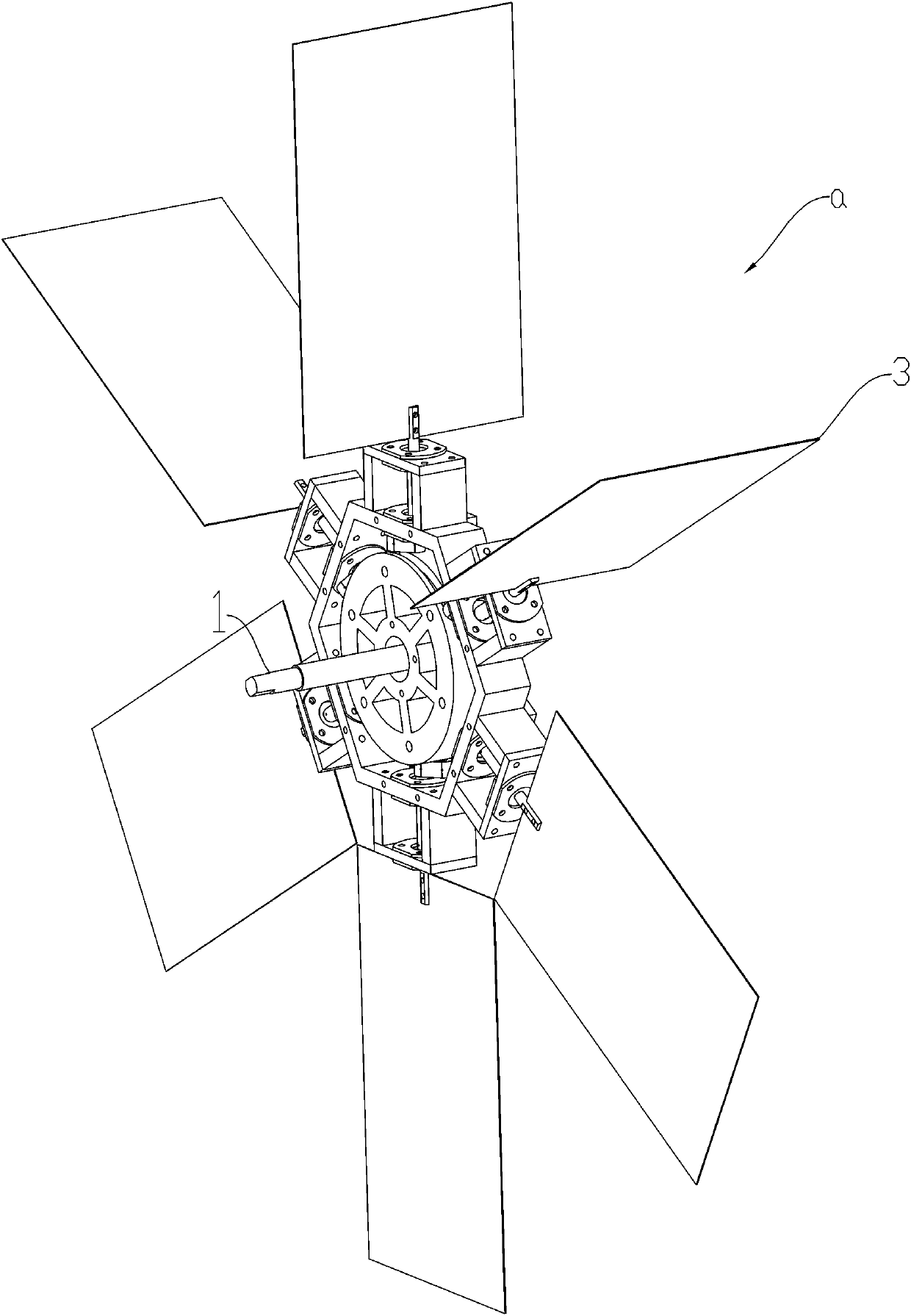

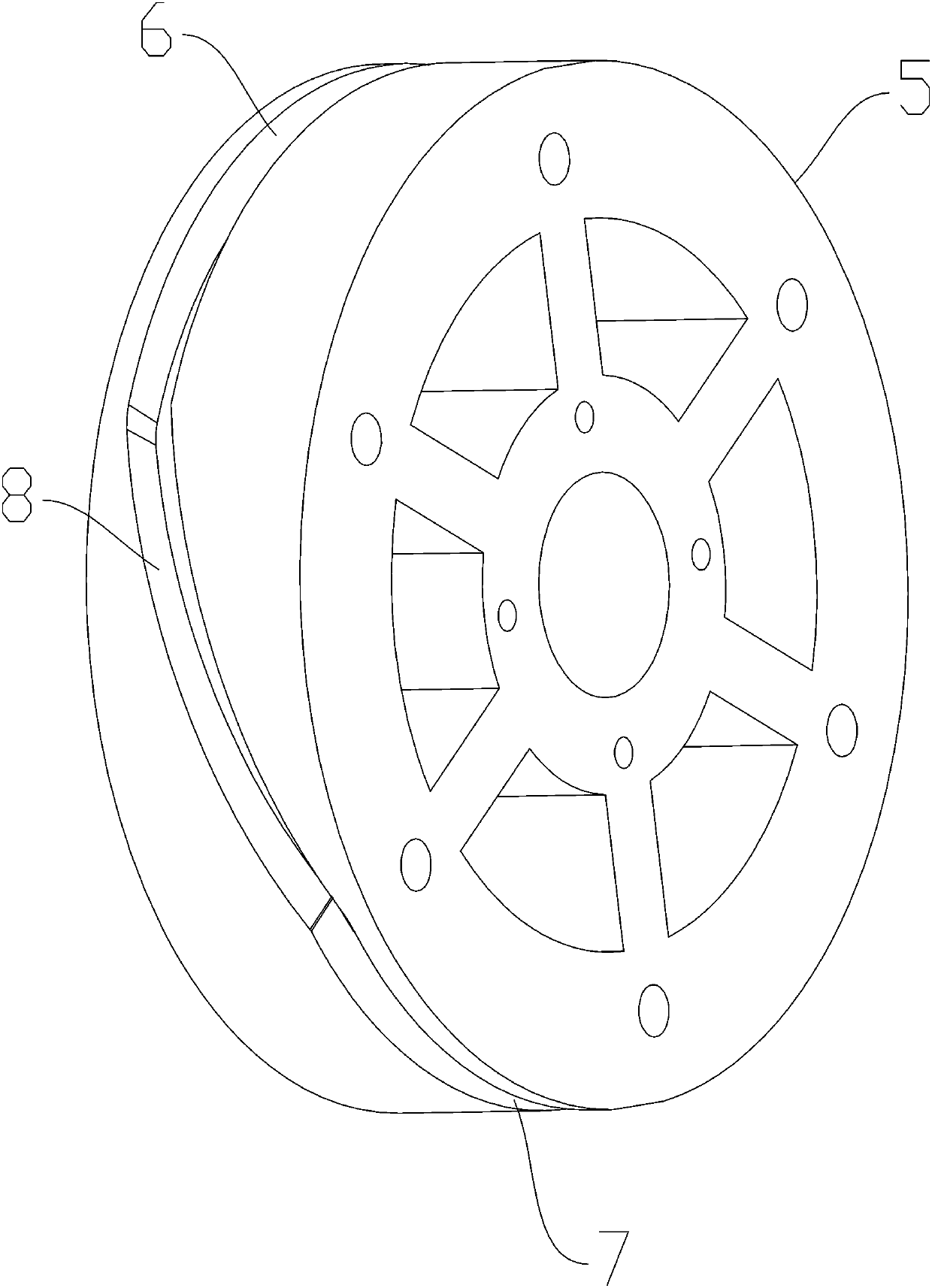

[0023] Such as Figure 1 to Figure 7 As shown, the pitch impeller of the present invention includes a main shaft 1 , a wheel frame 2 fixed at one end of the main shaft 1 , and a group of blades 3 distributed around the wheel frame 2 . The synchronous rotation of the paddle 3 and the wheel frame 2 drives the rotation of the main shaft 1 . There is a rotatable connection between the paddle 3 and the wheel frame 2 . A pitch-changing mechanism 4 is provided between the main shaft 1 and the wheel frame 2 . When the blade 3 rolls above the center line o of the wheel frame 2, the direction of the blade 3 above the center line o is changed by the pitch-changing mechanism 4, so that the blade 3 and the wheel Frame 2 is vertical, forms the windward side. When the paddle 3 rolls below the center line a of the wheel frame 2, the pitch change mechanism 4 changes the direction of the paddle 3 below the center line o, so that the paddle 3 and the wheel rack 2 parallel.

[0024] Preferab...

Embodiment 2

[0030] Such as Figure 8 As shown, the wind power generator of the present invention includes a column 15, and the pitch-changing impeller a described in Embodiment 1 is arranged symmetrically on both sides of the column 15, and the cylindrical cam 5 of the pitch-changing impeller a passes through a set of mounting columns 17 is fixedly connected with the column 15. The other end of the main shaft 1 is connected with a pulley 16 . The rotor of the generator set is driven to rotate by the pulley 16 to generate electricity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com