Method for synthesizing succinonitrile or adiponitrile

A synthesis method and technology for succinonitrile are applied in the field of synthesis of succinonitrile or adiponitrile, and achieve the effects of low human and environmental harm, high yield, and suitability for industrialized mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

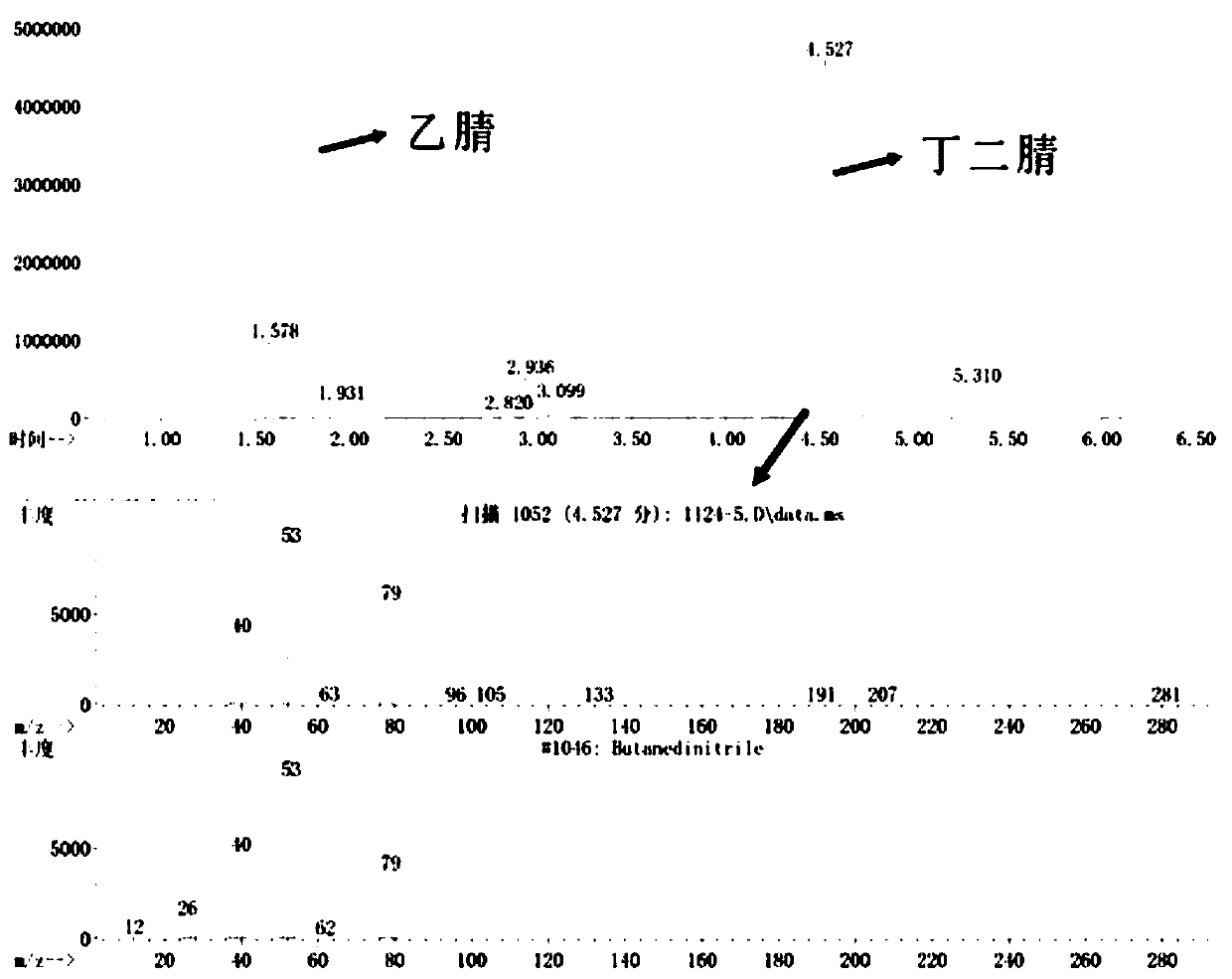

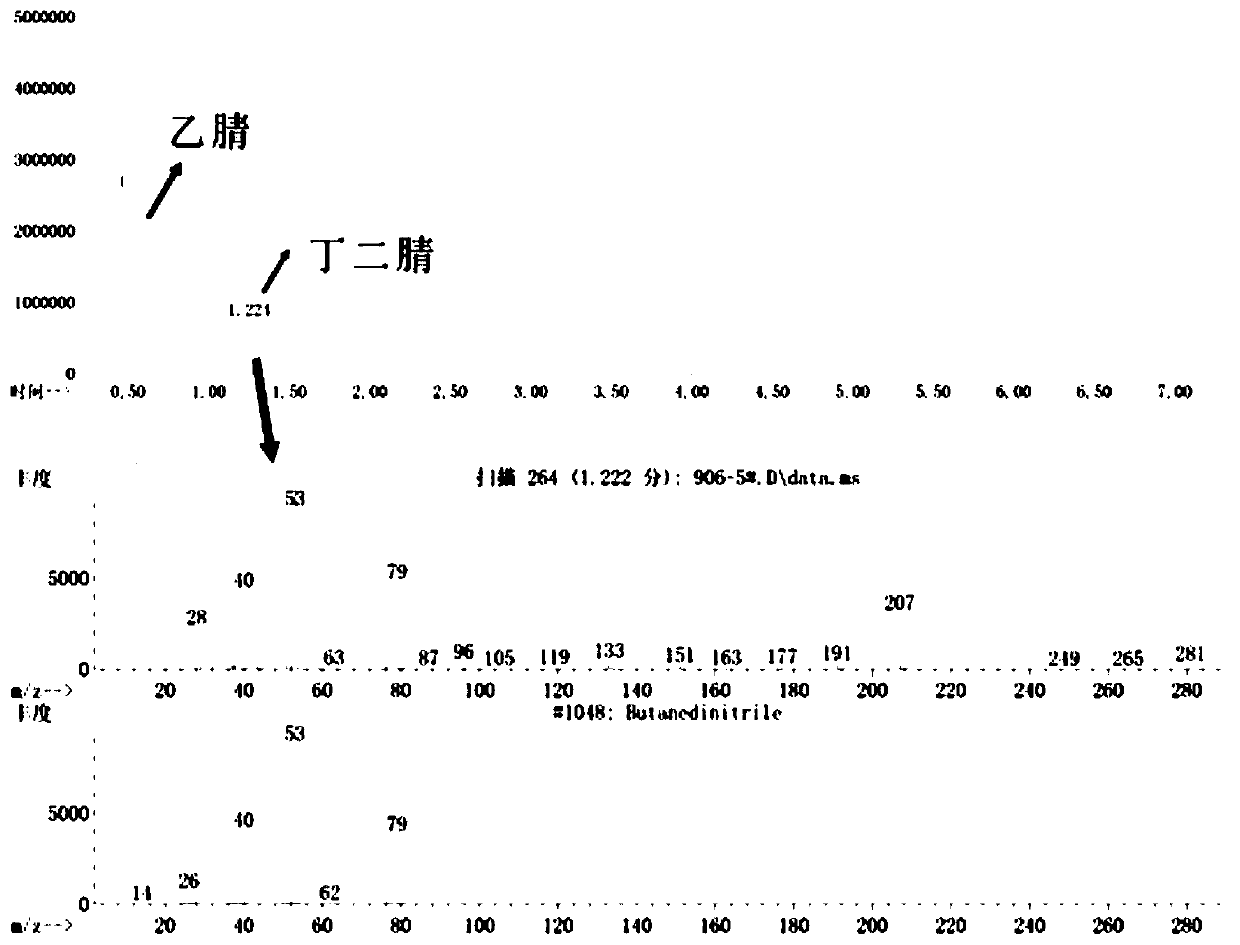

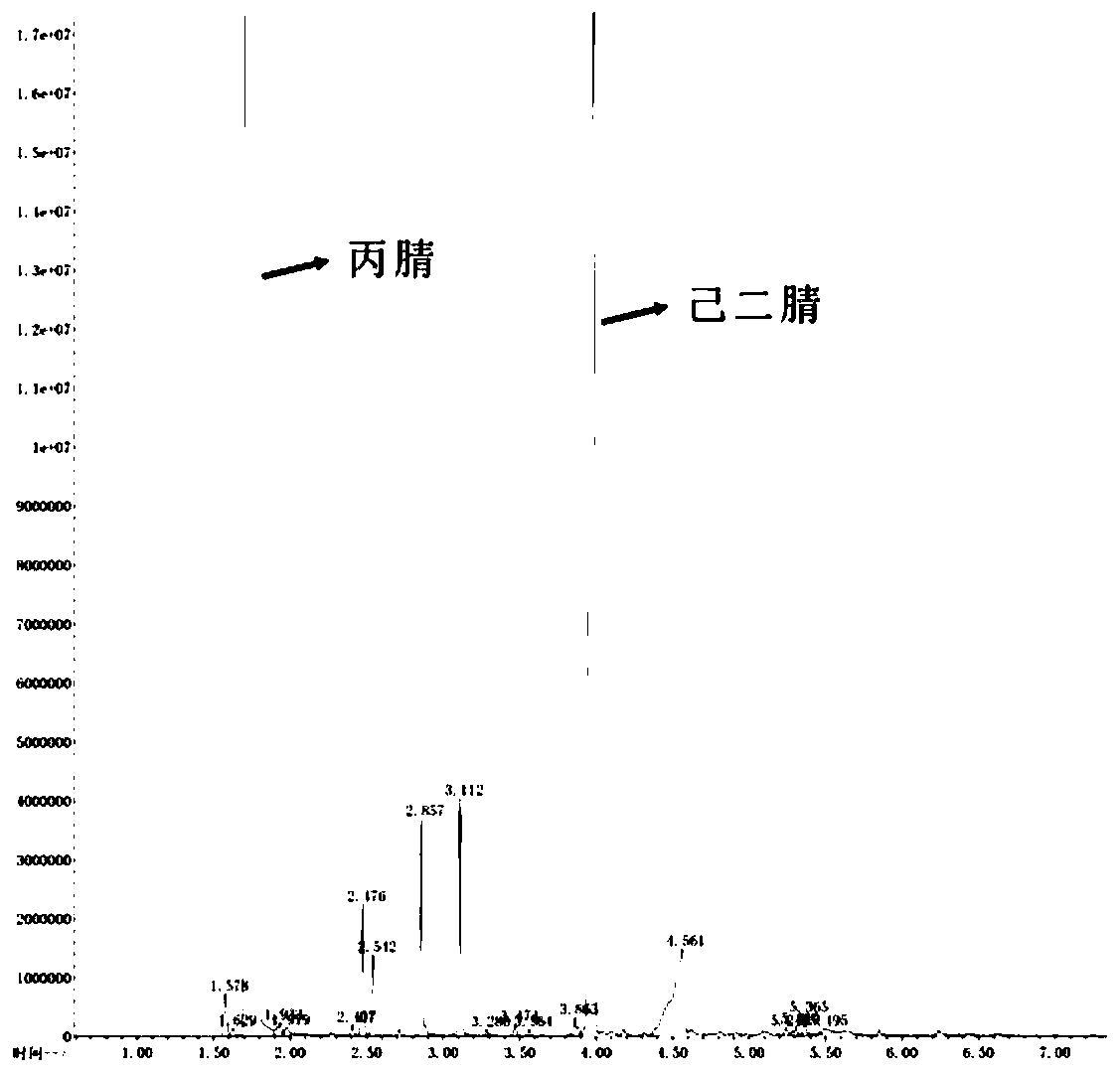

Image

Examples

Embodiment 1

[0047] Add 102g of acetonitrile, 10g of ferrous sulfate, and 42g of hydrogen peroxide (about 30g of water) into the flask equipped with mechanical stirring, then start stirring and raise the temperature to 30°C, feed nitrogen, the reaction pressure is 1atm (one atmospheric pressure), and keep warm for 5h After the reaction is completed and the solid is recovered, the liquid is distilled under reduced pressure to obtain the finished product of succinonitrile, the product purity is 95%, and the yield is 15%.

Embodiment 2

[0049]Add 102g of acetonitrile, 10g of ferrous sulfate, and 42g of hydrogen peroxide (about 30g of water) into the flask containing the magneton, feed high-pressure nitrogen to pressurize to 2atm (2 atmospheres), add magnetic stirring, and then heat up to 35°C and keep warm 6h, after the reaction was completed and the solid was recovered, the liquid was distilled under reduced pressure to obtain the finished product of succinonitrile with a purity of 97% and a yield of 18%.

Embodiment 3

[0051] Add 500g of acetonitrile, 60g of oxyferric chloride, and 105g of hydrogen peroxide (with a water content of about 75g) into a flask equipped with mechanical stirring, then start stirring and heat up to 50°C, and nitrogen gas is introduced, and the reaction pressure is 1atm (one atmosphere) , keep warm for 8h, after the reaction is completed, recover the solid, and distill under reduced pressure to obtain the finished product of succinonitrile, the product purity is 94%, and the yield is 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com