LED lamp radiator and machining method thereof

A technology for LED lamps and radiators, applied in metal processing equipment, manufacturing tools, heat treatment equipment, etc., can solve the problems of large aspect ratio of heat sink grooves, large external dimensions, asymmetry, etc., to ensure heat dissipation efficiency, improve Effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

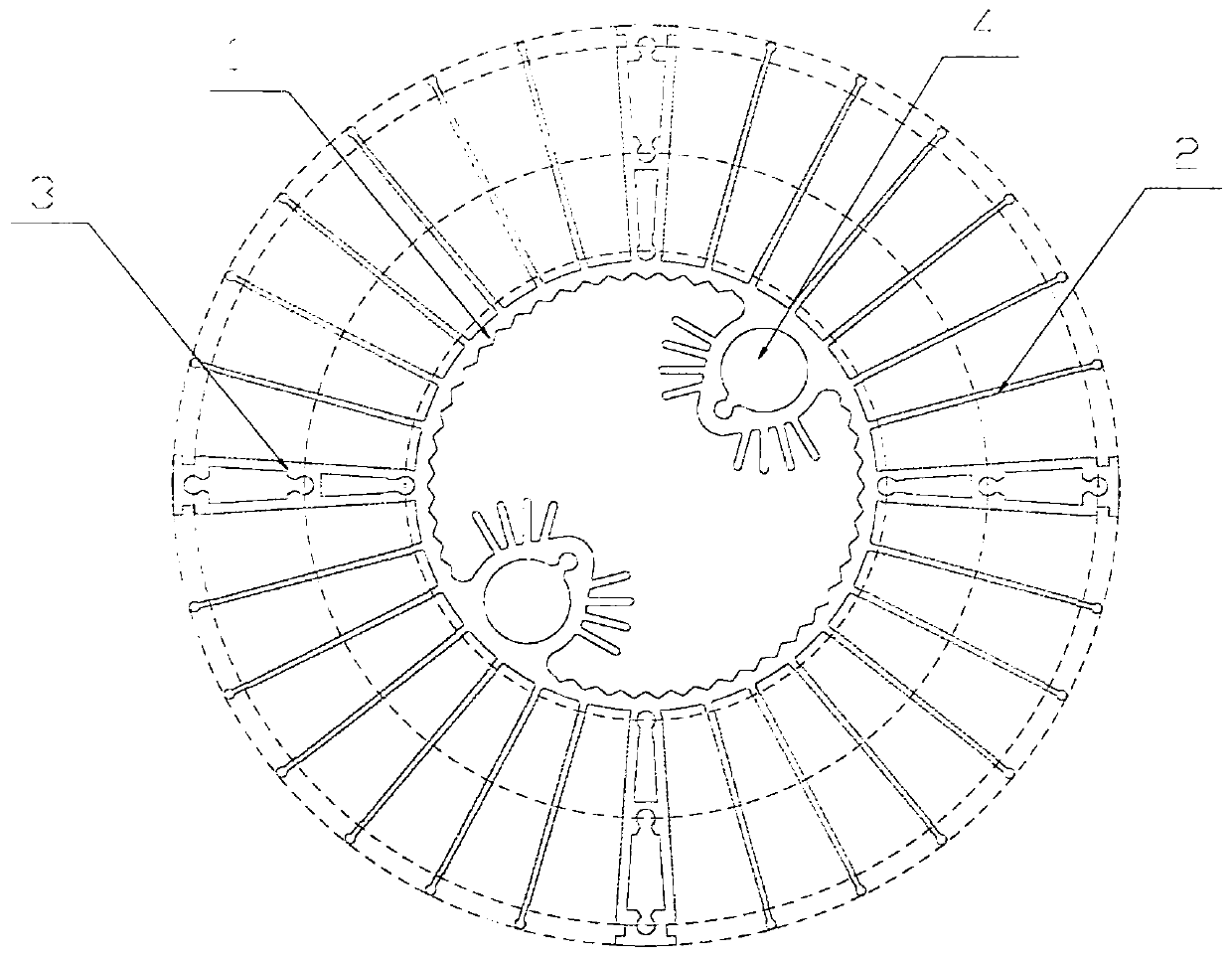

[0035] see figure 1As shown, a LED lamp heat sink in this embodiment has a circular structure as a whole, including a circular base 1, and a number of cooling fins 2 are arranged on the periphery of the circular base 1. The heat dissipation fins 2 are radially and evenly spaced, and there are 24 heat dissipation fins 2 in total. The rubber strip mounting seats 3 are arranged on the periphery of the circular base 1 in equal parts, and between two adjacent rubber strip mounting seats 3 There are 6 heat dissipation fins 2, and the rubber strip mounting seat 3 is arranged radially, and the length is consistent with the heat dissipation fins 2. Two cavities are provided on the rubber strip mounting seat 3 for setting the rubber strips. On the one hand The weight of the radiator can be reduced, the material can be saved, and at the same time, it ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap