Flat-panel display defect detection method and device

A flat panel display, defect detection technology, applied in the direction of instruments, image data processing, image enhancement, etc., can solve the problem of high requirements for hardware devices, and achieve the effect of high accuracy and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

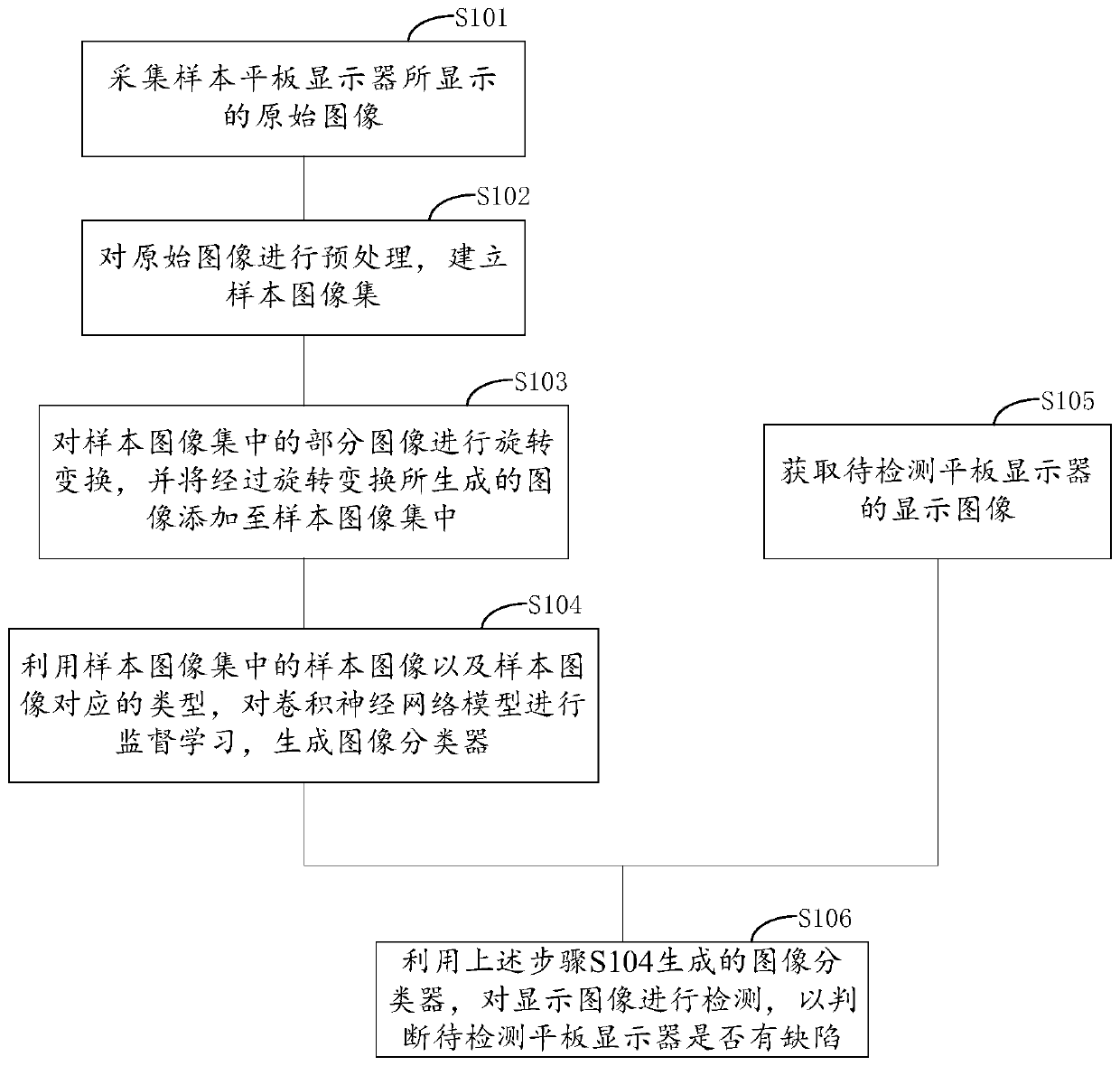

[0024] Based on the principles of the above invention, an embodiment of the present invention provides a flat panel display defect detection method, such as figure 1 As shown, the method includes:

[0025] S101. Collect an original image displayed on a sample flat panel display.

[0026] Wherein, the sample flat panel displays include flat panel displays with defects and flat panel displays without defects.

[0027] Specifically, in order to train the convolutional neural network model, it is necessary to collect a large number of images displayed by defective flat-panel displays as positive samples and images displayed by non-defective flat-panel displays as negative samples, so as to train the convolutional neural network. Perform supervised learning training.

[0028] When collecting the original image displayed on the sample flat panel display, it may be collected by using an optical device such as a camera, a video camera and the like to directly capture the image displ...

Embodiment 2

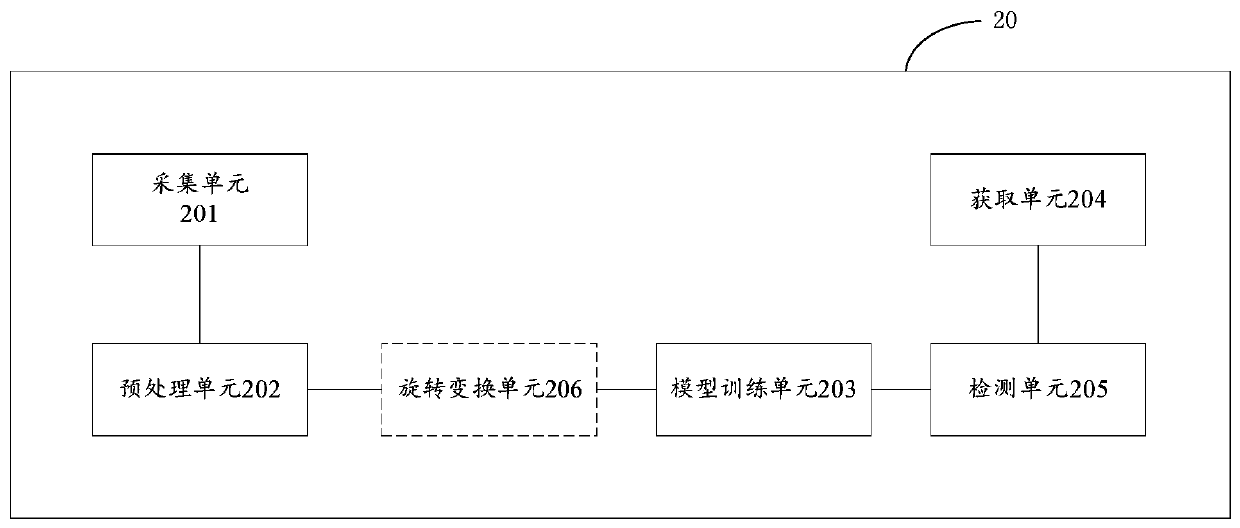

[0104] An embodiment of the present invention provides a defect detection device for a flat panel display, and the defect detection device for a flat panel display is used to implement the above defect detection method for a flat panel display. Such as image 3 As shown in FIG. 1 , it is a schematic diagram of a possible structure of the flat panel display defect detection device provided by the embodiment of the present invention. Specifically, the flat panel display defect detection device 20 includes: an acquisition unit 201 , a preprocessing unit 202 , a model training unit 203 , an acquisition unit 204 and a detection unit 205 . in:

[0105] The acquisition unit 201 is configured to acquire the original image displayed by the sample flat panel display; the sample flat panel display includes a defective flat panel display and a non-defective flat panel display;

[0106] A preprocessing unit 202, configured to preprocess the original image to establish a sample image set;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com