A construction mortar partition mixer

A mixer and mortar technology, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of material volume reduction, cracking, and influence of construction safety factor, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

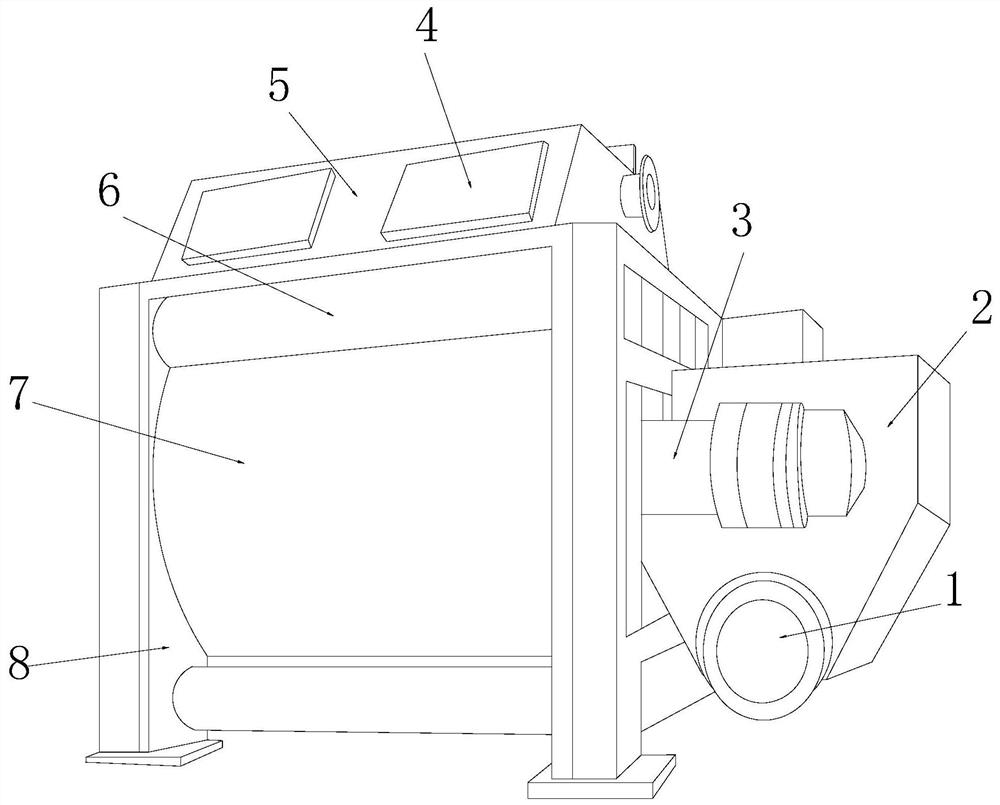

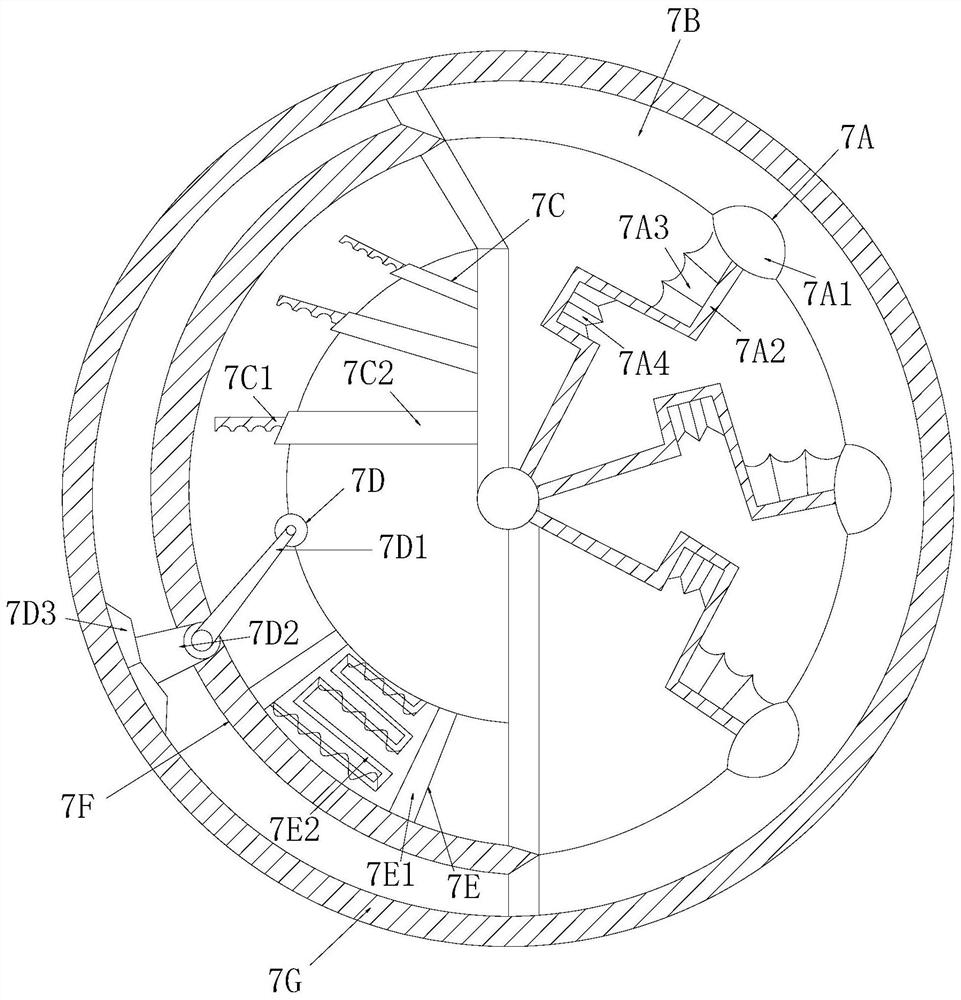

[0034] see Figure 1-Figure 6 , the present invention provides a construction mortar partition mixer, its structure includes: blower 1, vertical plate groove 2, shaft motor 3, feeding baffle 4, top shell cover 5, roller shaft pole 6, mortar stirring roller Groove 7, profile column block 8, described mortar sub-stirring roller groove 7 is mechanically connected with roller shaft column bar 6 and is parallel to each other, and described profile column block 8 is provided with four and is respectively nested in mortar sub-stirring roller groove 7 and On the left and right sides of the roller shaft pole 6, the feed baffle 4 is mechanically connected to the top shell cover 5 through a hinge and is on the same inclined plane, and the top shell cover 5 is nested in the mortar mixing roller groove 7 The shaft motor 3 is inserted on the right side of the mortar stirring roller groove 7 and the axes are collinear. The blower 1 is nested under the bottom of the vertical plate groove 2 an...

Embodiment 2

[0041] see Figure 1-Figure 6 , the present invention provides a kind of building mortar partition mixer, other respects are identical with embodiment 1, and difference is:

[0042] see figure 2 The spring frame damping block 7E is composed of a damping partition 7E1 and a folding rod spring wire frame 7E2. The damping partition 7E1 and the folding rod spring wire frame 7E2 adopt an interference fit and are on the same vertical plane. The internal damping chute is formed by the counterweight pressure of mud and sand on both sides of the folding rod spring wire frame 7E2 through the damping partition 7E1 The penetration effect ensures the combination of sand particles and mud parcels to form a mortar composition effect.

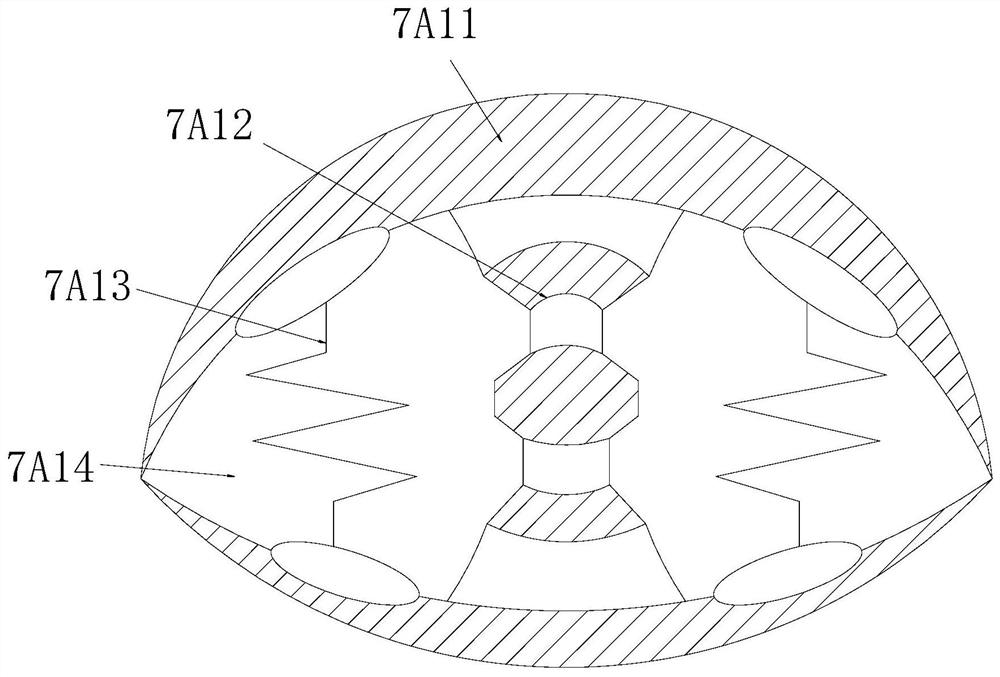

[0043] see Figure 6 The damping partition 7E1 is composed of a corrugated wire 7E11, a narrow fan plate 7E12, a triangular plate 7E13, and a spring wire 7E14. On the same vertical line, the triangular plate 7E13 is installed inside the narrow fan plate 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com