A control method for the tail tension solenoid valve of scraper machine

A control method and solenoid valve technology, applied in conveyors, transportation and packaging, etc., can solve the problems of slow response speed and poor control reliability of the tension solenoid valve, and achieve improved control reliability, fast response speed and high flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

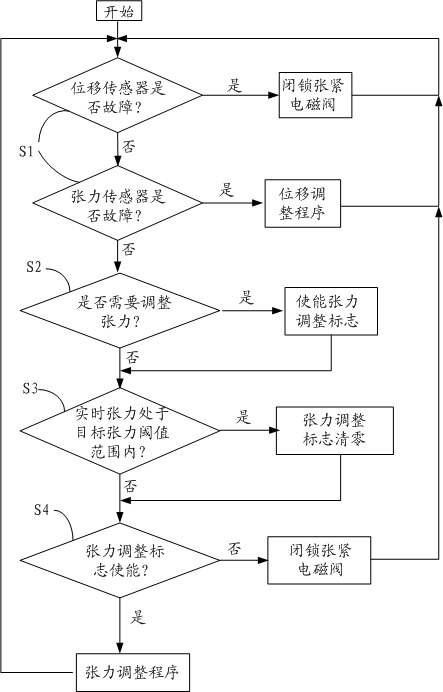

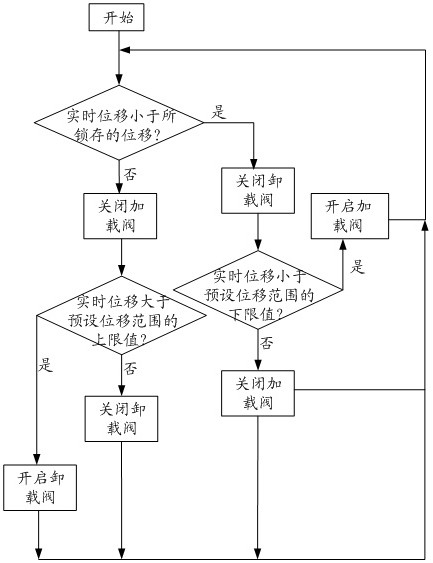

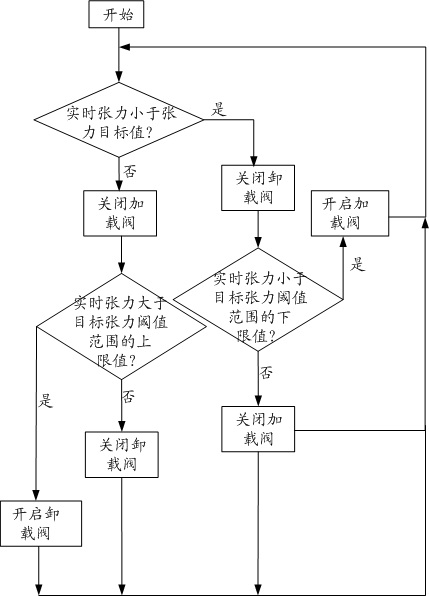

[0027] In order to realize the control of the tension solenoid valve flexibly and reliably, ensure that the tension of the scraper chain is within a certain reasonable range, neither the tension is too small to cause failures such as chain drop or jamming, nor is the tension too large to cause abrasion of the scraper , broken chain and other faults, this embodiment relates to a control method for the tail tension solenoid valve of scraper machine, see Figure 1 to Figure 3 As shown, the specific description is as follows.

[0028] S1: Determine whether the tension sensor and the displacement sensor are faulty. If both are faulty or only the displacement sensor is faulty, control the tension solenoid valve to lock and return to S1. If only the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com