A fast turning fixture for the turntable of a glue applicator

A technology of gluing machine and turntable, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of difficult installation and debugging, affecting production efficiency, and many electrical circuits, reducing electrical circuits and improving production. Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

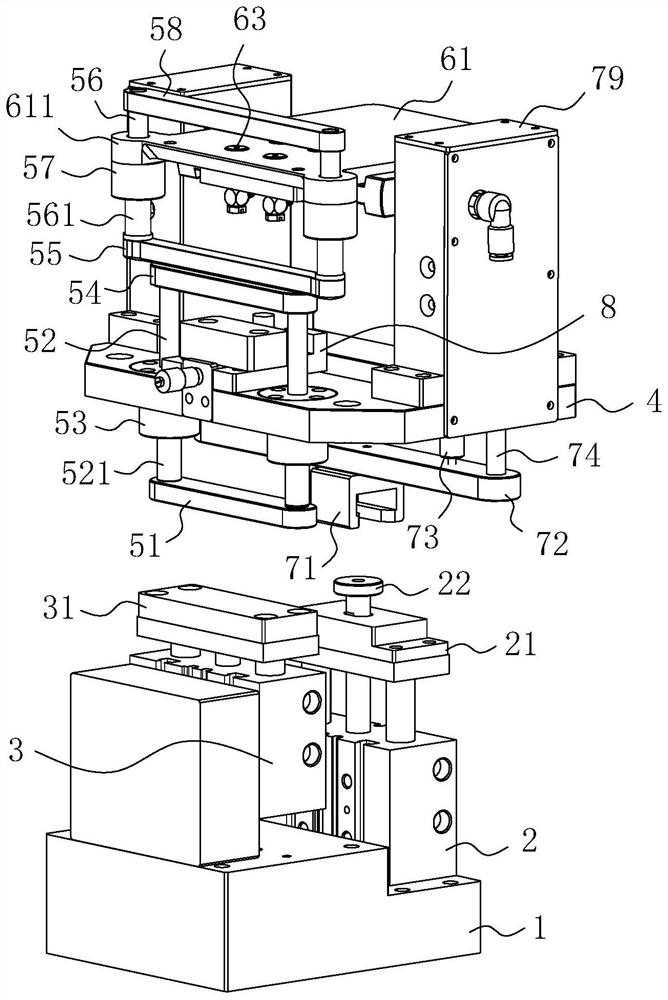

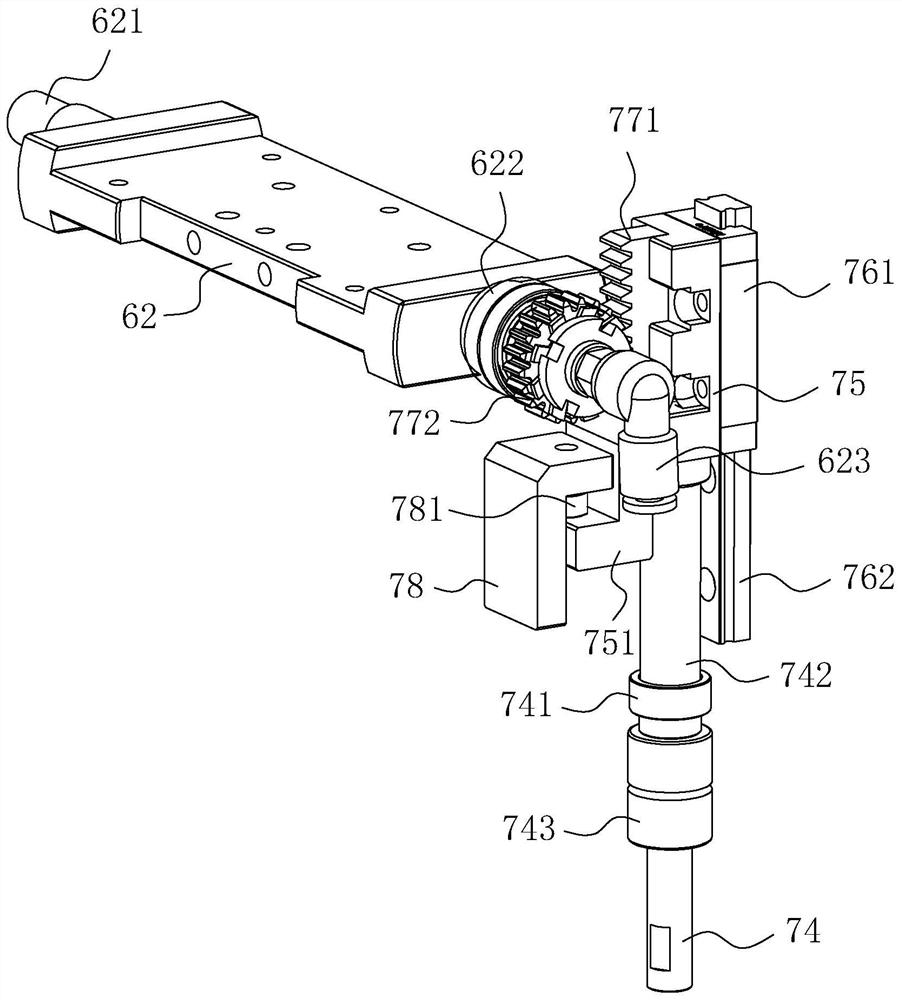

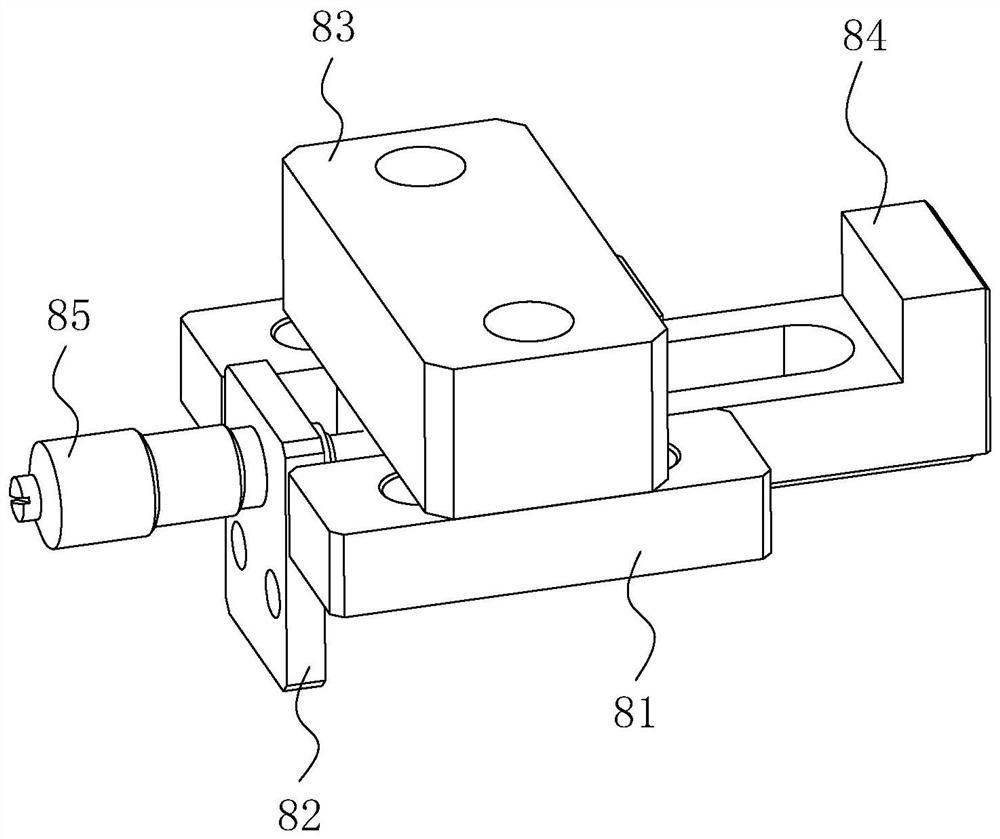

[0035] A fast flipping fixture for the turntable of a gluing machine, refer to figure 1 , which includes a fixed base plate 4 and a fixed base 1, the fixed base plate 4 is provided with an overturning actuator, the overturning actuator is provided with an automatic clamping mechanism, and the fixed base plate 4 is also provided with an unclamping actuator that cooperates with the automatic clamping mechanism ; The fixed base 1 is respectively provided with an unclip driving device and an overturning driving device.

[0036] refer to figure 1 , the unclamp driving device includes an unclamp cylinder 3 connected to the fixed base 1, the unclamp cylinder 3 is provided with a wear-resistant top plate 31 that can be in contact with the unclamp actuator, and the unclamp cylinder 3 can drive the wear-resistant top plate 31 along the vertical Move back and forth in a straight direction.

[0037] refer to figure 1 The turning drive device includes a turning cylinder 2 connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com