Clamp assembly for cable processing device and cable processing device

A component and fixture technology, applied in the direction of electrical components, cable/conductor manufacturing, circuits, etc., can solve the problems of complex structure and heavy fixture components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

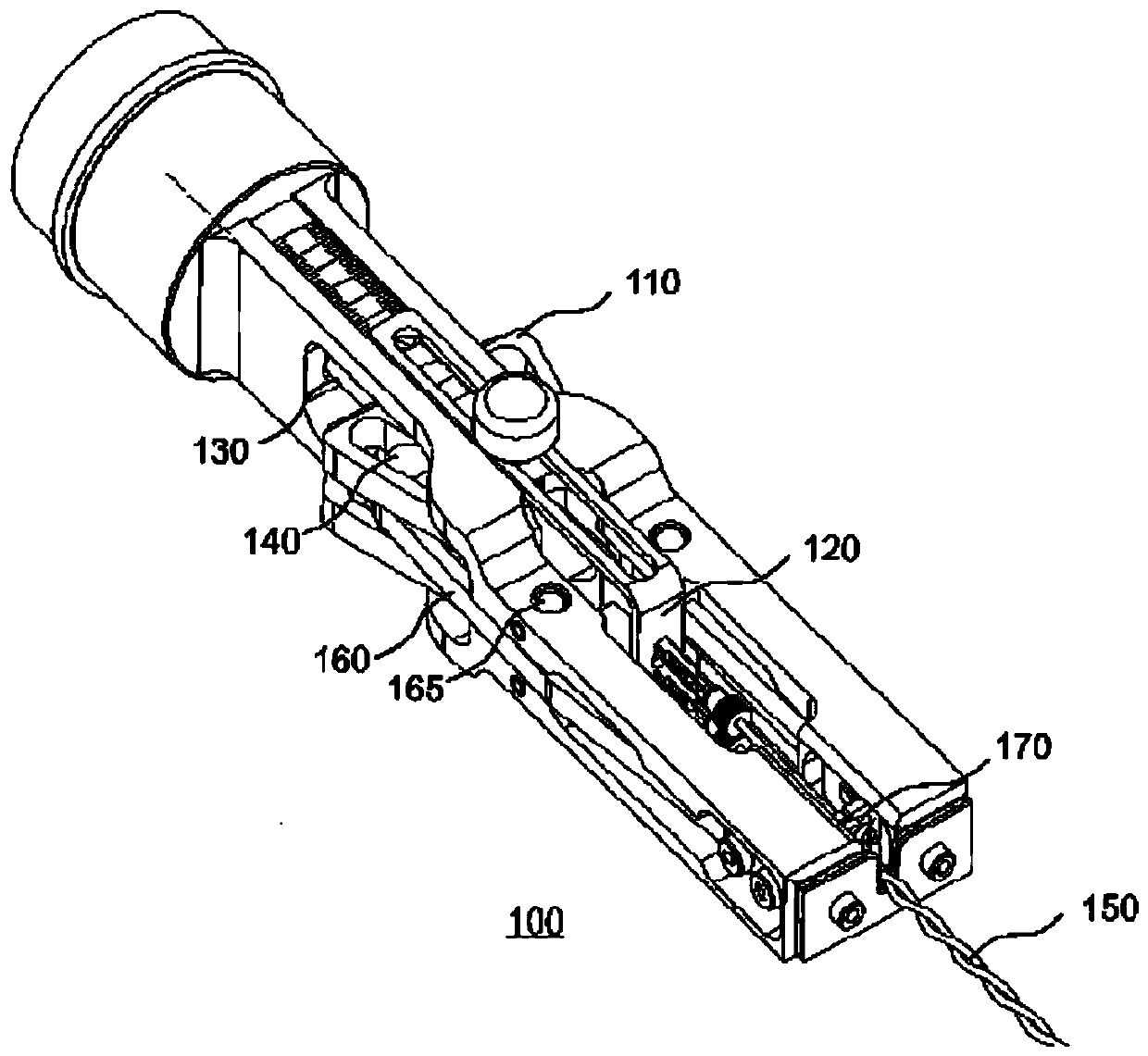

[0025] figure 1 A schematic perspective view of a prior art cable clamp 100 is shown. exist figure 1 Among them, the cable clamp 100 includes a pair of jaws 170 for clamping ends of a pair of cables 150 inserted into a region between the jaws 170 . The limit stopper 120 ensures an appropriate length of insertion of the pair of cables 150 in the axial direction. The slider 110 is arranged on the piston rod 130 of the cable clamp 100 . The piston rod 130 is part of a pneumatically operated cylinder and is substantially movable back and forth along the common axis of the cable 150 and the cable clamp 100 .

[0026] Bolts 140 on either side of slider 110 engage corresponding slots in each of a pair of levers 160 . As the piston rods 130 move, each control rod 160 pivots in a substantially synchronous manner about a rotational axis 165 such that the jaws 170 grip the pair of cables 150 substantially at a central position.

[0027] The mechanical complexity of the bolt 140, sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com