Active aero system in-mold assembly hinge modular frame

A technology of in-mold assembly and modularization, which is applied in the direction of cooling combination layout of the power unit, component optimization, power unit, etc., can solve the problem of additional floor space and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following description of the preferred embodiments is merely exemplary in nature, and is not intended to limit the present invention, the application or use of the present invention.

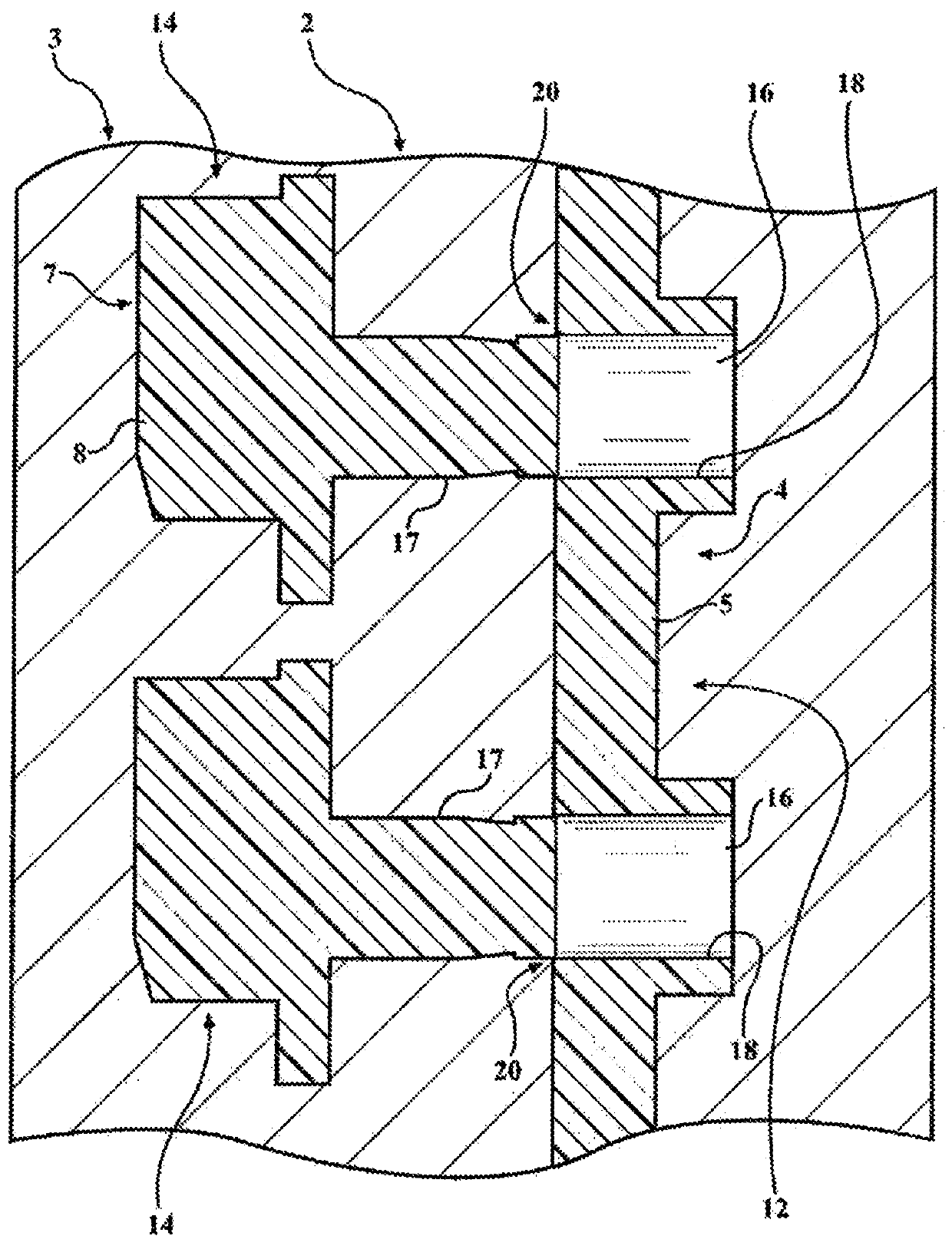

[0023] Referring generally to the drawings, an in-mold assembly of an active pneumatic hinge modular frame is provided, which allows the joining of multiple components assembled directly from the molding process tool. These components include, for example, blade end pivots, blade end stops, drive links, and / or frame end stops. The geometric factors in the in-mold assembly (IMA) design contribute to the final assembly of the system, which is preferably the actuator that drives the blade interface.

[0024] Geometric factors allow components (eg, blade end pivots, blade end stops, drive links, frame end stops, etc.) to be directly attached from the mold and assembled into a single part. These components provide various functions in the complete system, including rotary engagement and torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com