Heat management module of engine cooling system and engine cooling system

A technology for engine cooling and thermal management, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve problems such as poor combustion conditions, reduced heat dissipation, and reduced service life of parts, so as to reduce processing costs and processing difficulties , reduce temperature fluctuations, reduce the effect of cold and heat shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

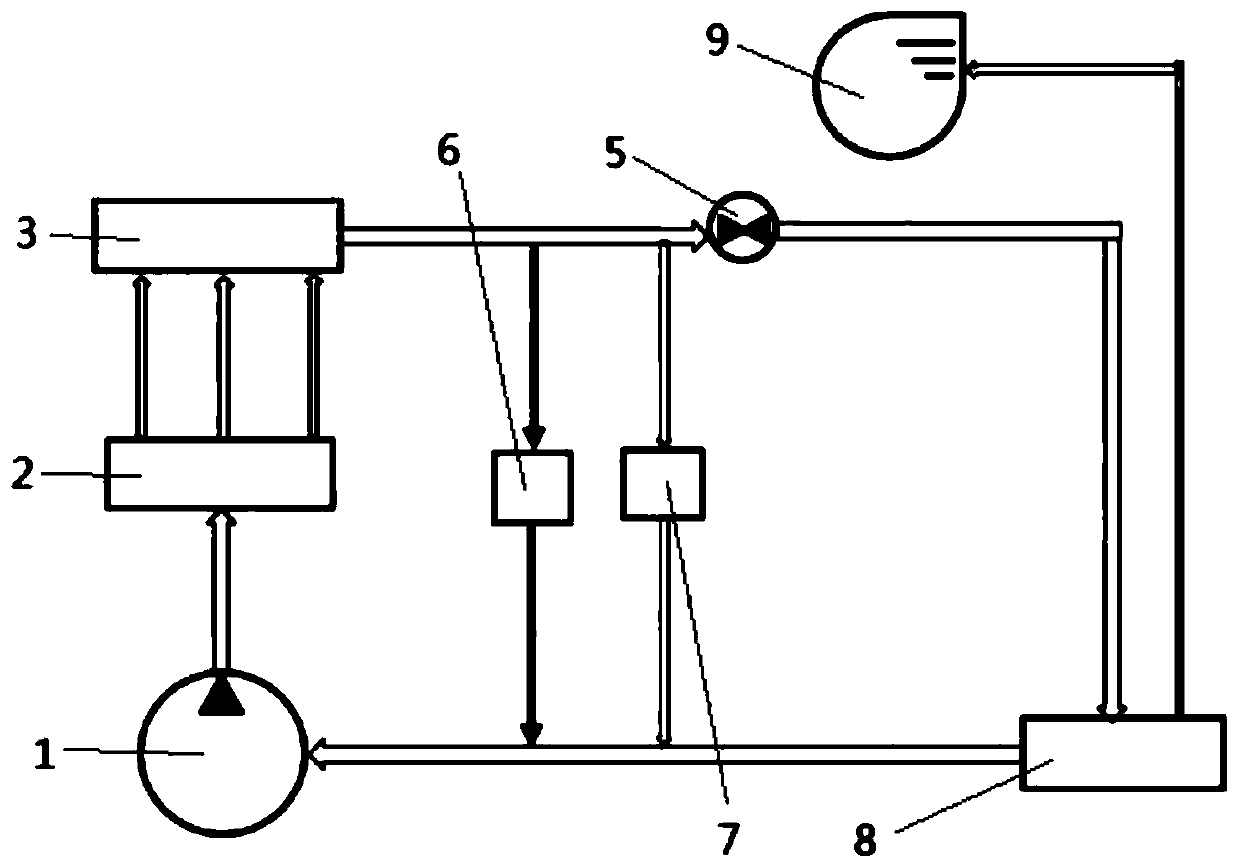

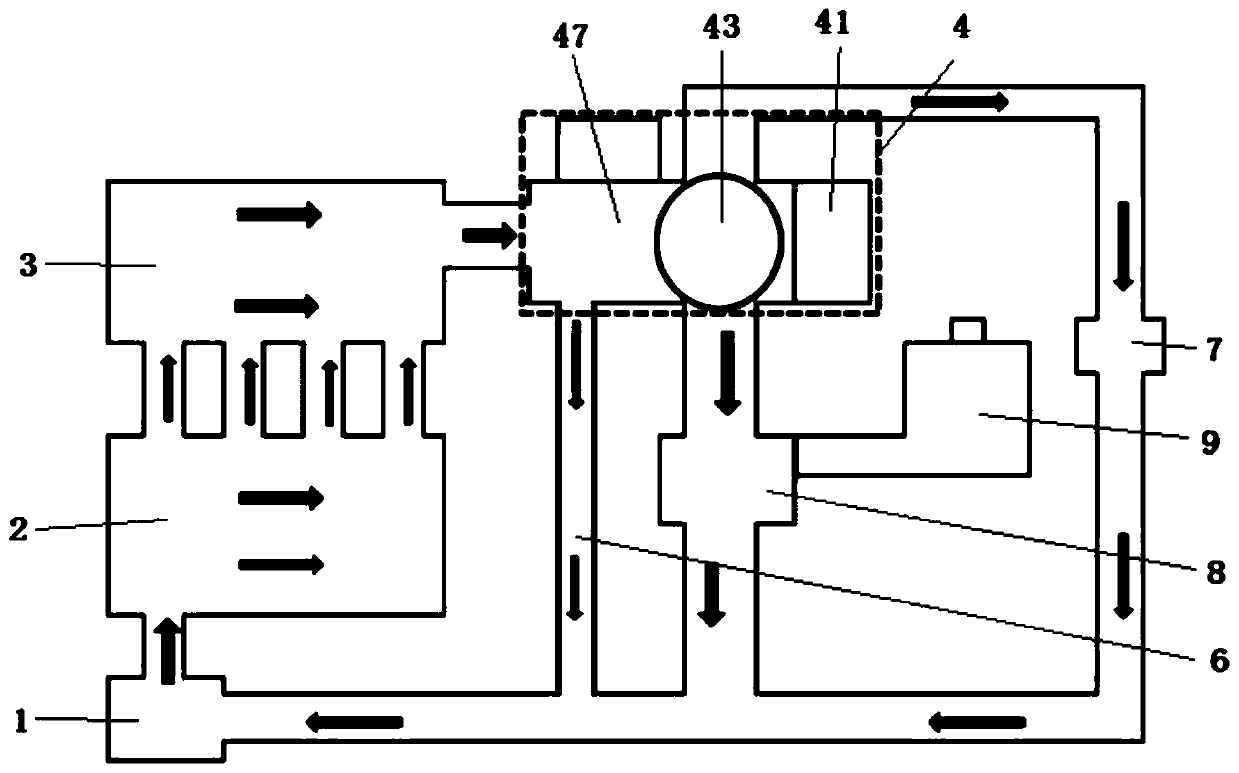

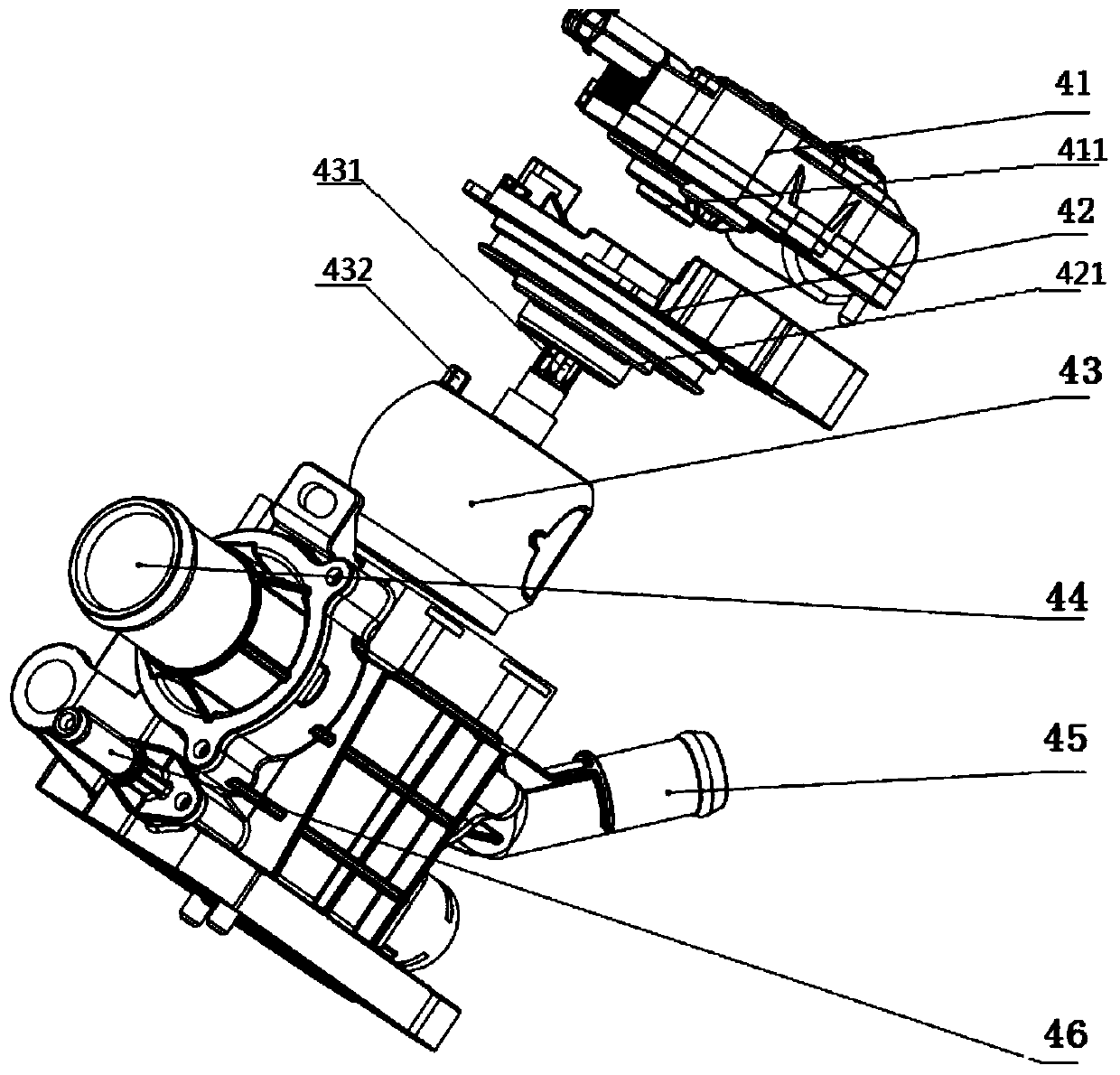

[0024] Such as Figure 2-Figure 6 As shown, the engine cooling system thermal management module 4 in this embodiment includes a housing, an actuator 41, and a ball valve 43. The actuator 41 is installed on the housing, and the ball valve 43 is installed in the housing and is connected to the housing. The output shaft of the actuator 41 is in transmission connection, and the housing is provided with a housing water inlet for communicating with the water outlet of the engine cylinder head water jacket 3, an HVAC pipe 45 for communicating with the HVAC 7, and a In the radiator pipe 44 communicating with the radiator 8, the ball valve 43 includes a spherical valve core, and the spherical valve core is provided with a water inlet that is connected to the water inlet of the housing for connecting to the HVAC pipe 45 The docking heating valve port 433 and the radiator valve port 434 for docking with the radiator pipe 44; the actuator 41 can drive the ball valve 43 to rotate, thereby ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap