A resin-type no-cleaning flux paste

A solder paste and no-cleaning technology, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve problems such as environmental pollution, affecting the reliability of electronic devices, and corrosion of components around solder joints, so as to improve welding Effect of quality, good aging resistance, good solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

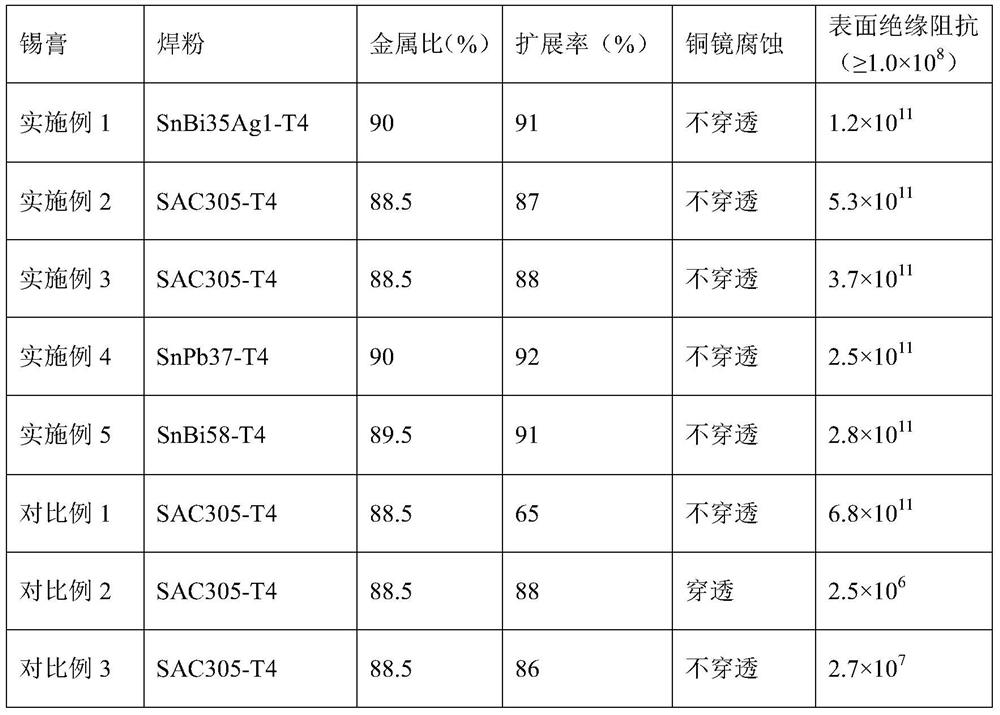

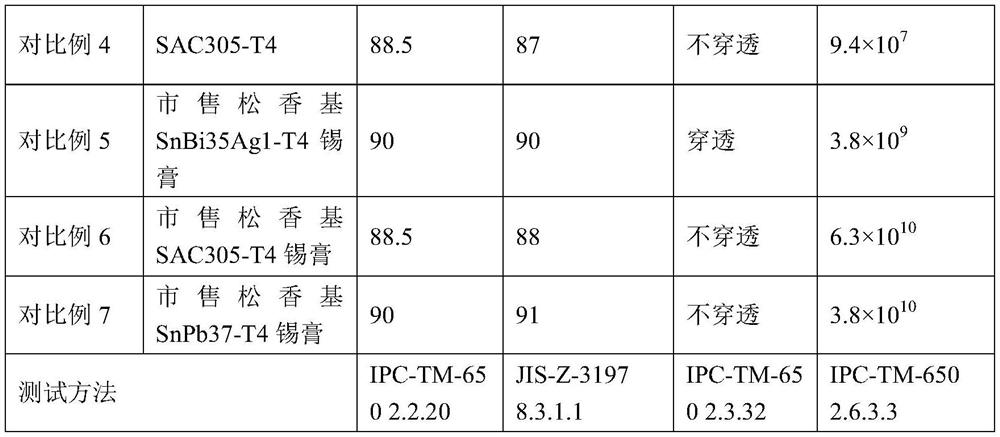

Examples

Embodiment 1

[0036] Embodiment 1 A kind of resin type no-clean soldering flux paste

[0037] A resin-type no-cleaning flux paste provided in this embodiment is composed of the following raw materials in percentage by weight: 20% of C5 hydrogenated petroleum resin, 5% of DCPD resin, 5% of terpene resin P-125, methyl Hydroquinone 1%, Succinic Acid 4%, Adipic Acid 8%, Modified Hydrogenated Castor Oil 8%, Diethylene Glycol Hexyl Ether 29% and 2-Ethyl-1,3-Hexanediol 20% .

[0038] The preparation method of above-mentioned flux paste comprises the following steps:

[0039] Mix C5 hydrogenated petroleum resin, DCPD resin, terpene resin P-125, diethylene glycol hexyl ether and 2-ethyl-1,3-hexanediol, stir at 140°C for 30min, then add methyl Hydroquinone, succinic acid, adipic acid and modified hydrogenated castor oil were stirred for 20 minutes, and then cooled to room temperature under stirring conditions.

Embodiment 2

[0040] Embodiment 2 A kind of resin type no-clean soldering flux paste

[0041] A resin-type no-clean soldering flux paste provided in this embodiment is composed of the following raw materials in percentage by weight: C9 hydrogenated petroleum resin 15%, terpene resin P-105 5%, terpene resin P-115 20% %, methyl hydroquinone 3%, phenylsuccinic acid 5%, fatty polyamide 5%, tripropylene glycol butyl ether 35% and 2-ethyl-1,3-hexanediol 12%.

[0042] The preparation method of above-mentioned flux paste comprises the following steps:

[0043]Mix C9 hydrogenated petroleum resin, terpene resin P-105, terpene resin P-115, tripropylene glycol butyl ether and 2-ethyl-1,3-hexanediol, stir at 120°C for 40min, then add in sequence Methyl hydroquinone, phenylsuccinic acid and fatty polyamide, stirred for 30min, then cooled to room temperature while stirring.

Embodiment 3

[0044] Embodiment 3 A kind of resin type no-clean soldering flux paste

[0045] A resin-type no-clean flux paste provided in this embodiment is composed of the following raw materials in weight percentage: 2% of C5 / C9 copolymer resin, 3% of DCPD resin, 15% of terpene resin P-105, p-hydroxy Benzoic acid 4%, malic acid 4%, adipic acid 5%, modified hydrogenated castor oil 4%, fatty polyamide 8% and diethylene glycol hexyl ether 55%.

[0046] The preparation method of above-mentioned flux paste comprises the following steps:

[0047] Mix C5 / C9 copolymer resin, DCPD resin, terpene resin P-105, and diethylene glycol hexyl ether, stir at 150°C for 30 minutes, then add p-hydroxybenzoic acid, malic acid, adipic acid, modified Hydrogenated castor oil and fatty polyamide, stirred for 20min, then cooled to room temperature while stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com