Diesel particulate filter loaded with macroporous perovskite oxide and its application

A technology of perovskite oxides and particle traps, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor high temperature stability, and achieve It is not easy to fall off, the method is practical and effective, and the effect of efficient catalytic oxidation removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

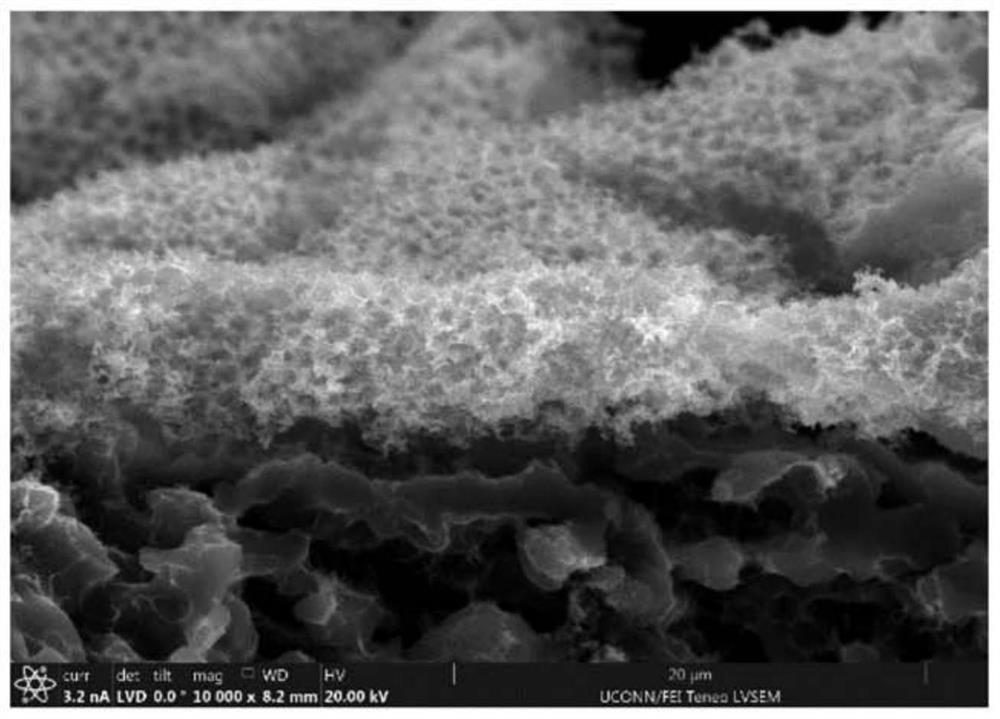

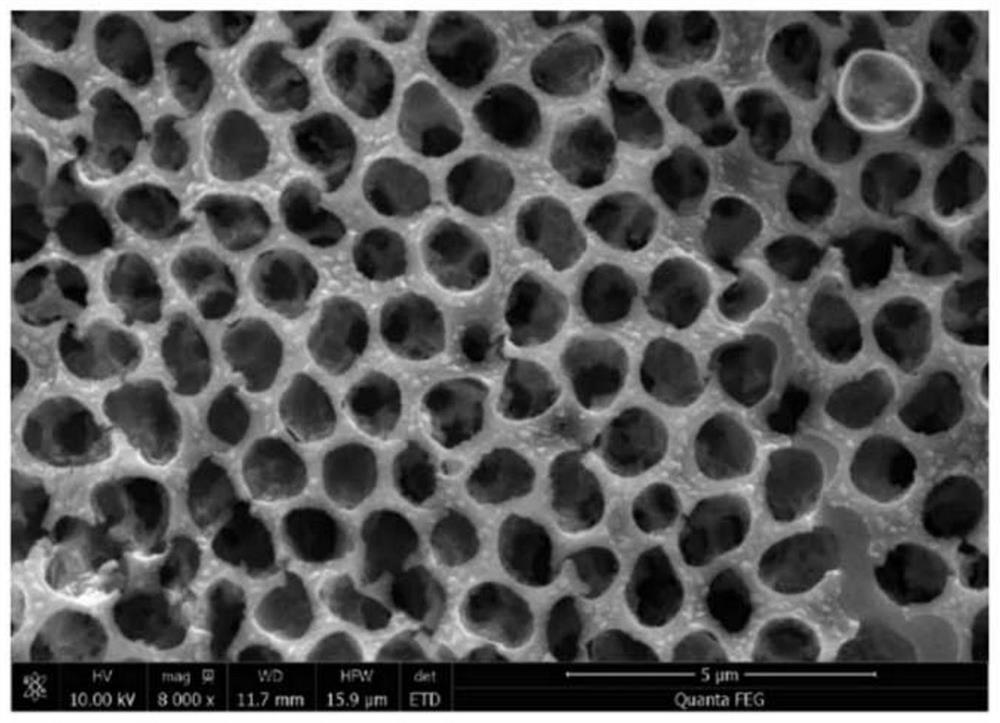

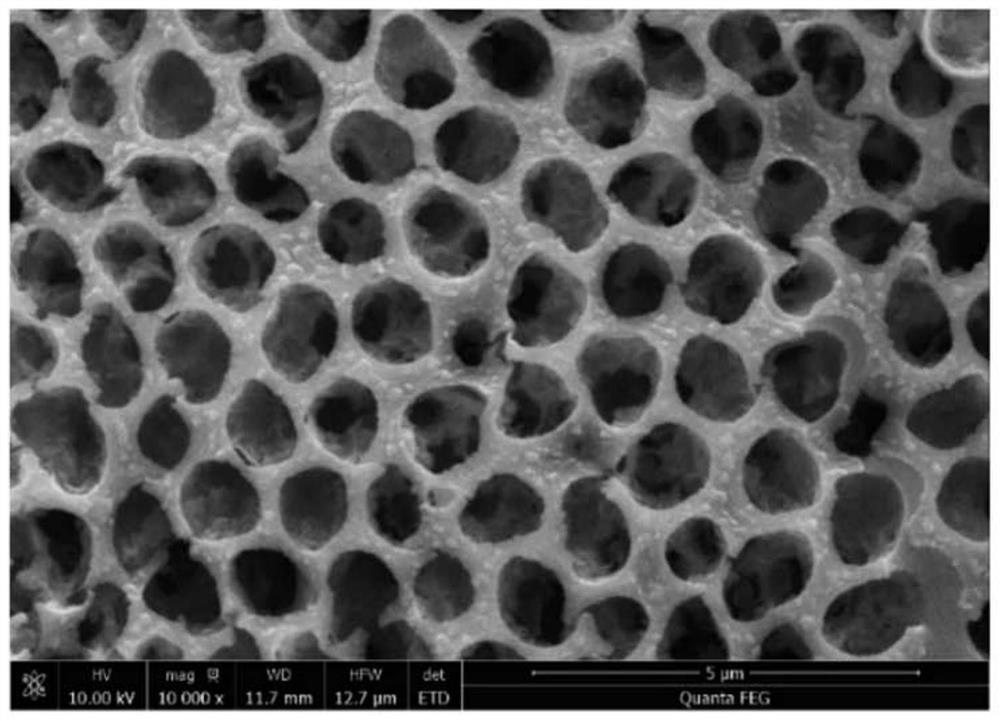

[0053] This embodiment provides a three-dimensional ordered macroporous perovskite La 0.8 K 0.2 CoO 3 The method for skeleton growth to the surface of a diesel particulate filter (DPF), the specific steps are as follows:

[0054] (1) Cleaning of DPF substrate

[0055] A commercial DPF substrate (channel 1.5mm×1.5mm) was cut into cube samples with a size of 1.5cm×1.5cm×1cm, followed by ultrasonic cleaning with distilled water, hexane, acetone and ethanol. The cleaning time of each solvent is 10 minutes; after cleaning, put the DPF substrate in an oven at 80° C. for 2 hours to dry for use.

[0056] (2) Perovskite La 0.8 K 0.2 CoO 3 Preparation of precursor sol

[0057] Dissolve 1.92mM lanthanum nitrate, 0.48mM potassium nitrate, and 2.4mM cobalt nitrate in a mixed solvent of 15ml ethylene glycol and 10mL methanol, ultrasonically dissolve and disperse it completely, then stir continuously at room temperature for 4h, and finally stand still for 24h to obtain calcium Titani...

Embodiment 2

[0075] In order to further evaluate the catalytic activity of the catalyst of the present invention, the present invention uses soot particulate matter catalytic combustion activity evaluation experiment and soot particulate matter loading experiment for evaluation.

[0076] The catalytic combustion activity evaluation test of soot particles was carried out in a fixed-bed reactor simulated by a quartz tube with a diameter of 23mm. Pack 800 mg of the monolithic catalyst (about 70-80 mg perovskite active component) manufactured in Example 1 of the present invention into a quartz tube, place the quartz tube in a tube furnace, and use a temperature program to raise the temperature from room temperature to To 700°C, the heating rate is 2°C / min. The reaction gas composition (volume fraction) is: 10% O 2 ,90% N 2 , the total flow rate is 100mL / min, and the mass space velocity is 75000mL / (g h). CO in the final reaction tail gas 2 The concentrations of CO and CO were analyzed onlin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com