Anti-static antibacterial fabric and preparation method thereof

An antibacterial fabric and anti-static technology, applied in the field of fabrics, can solve the problems that affect the drying quality of the fabric, cannot be dried uniformly, and affect the overall shape of the fabric, and achieve the effect of improving the stable shape, maintaining the overall shape, and avoiding wrinkles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

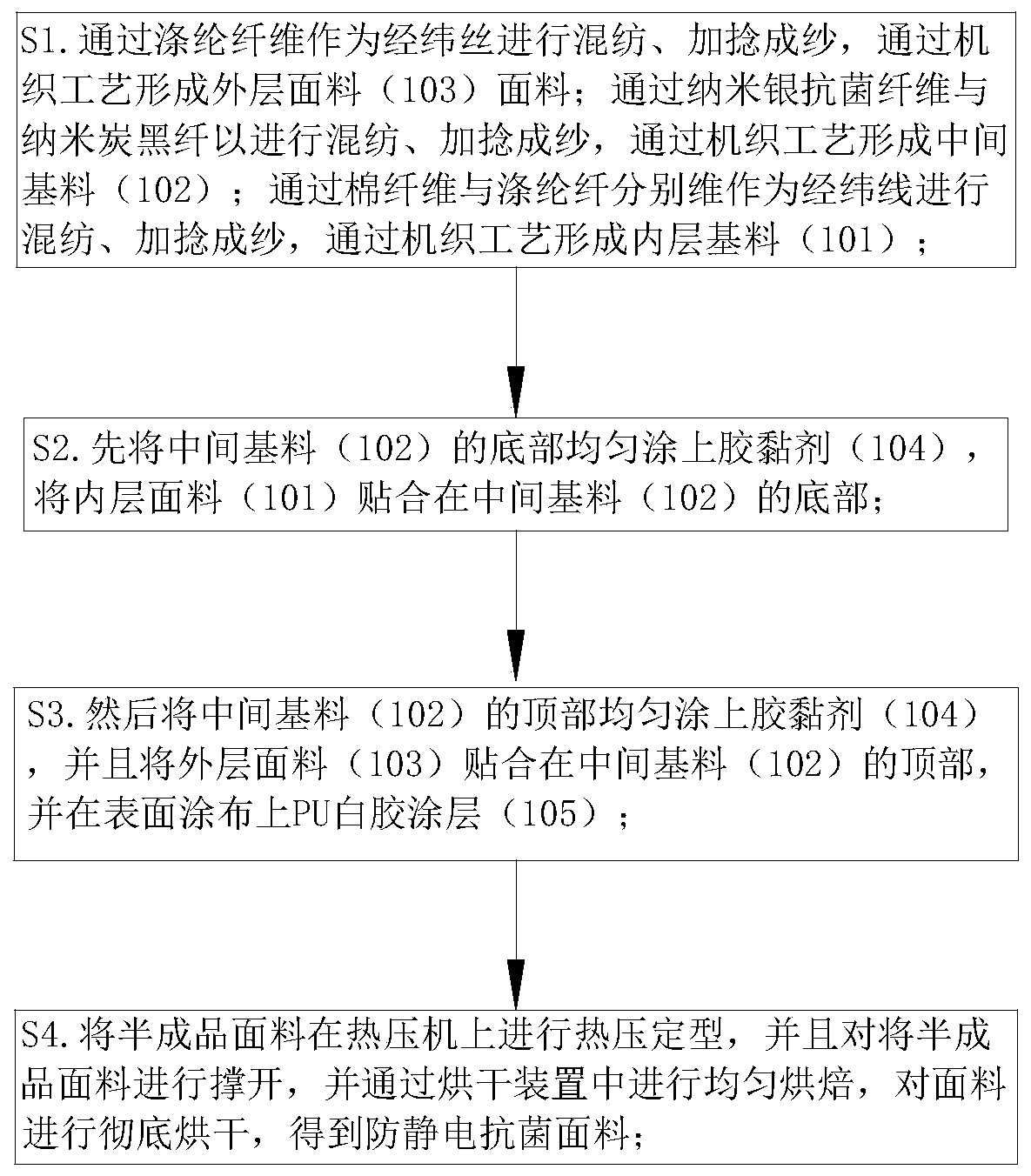

[0034] A preparation method for an antistatic antibacterial fabric, suitable for an antistatic antibacterial fabric, comprising the following steps:

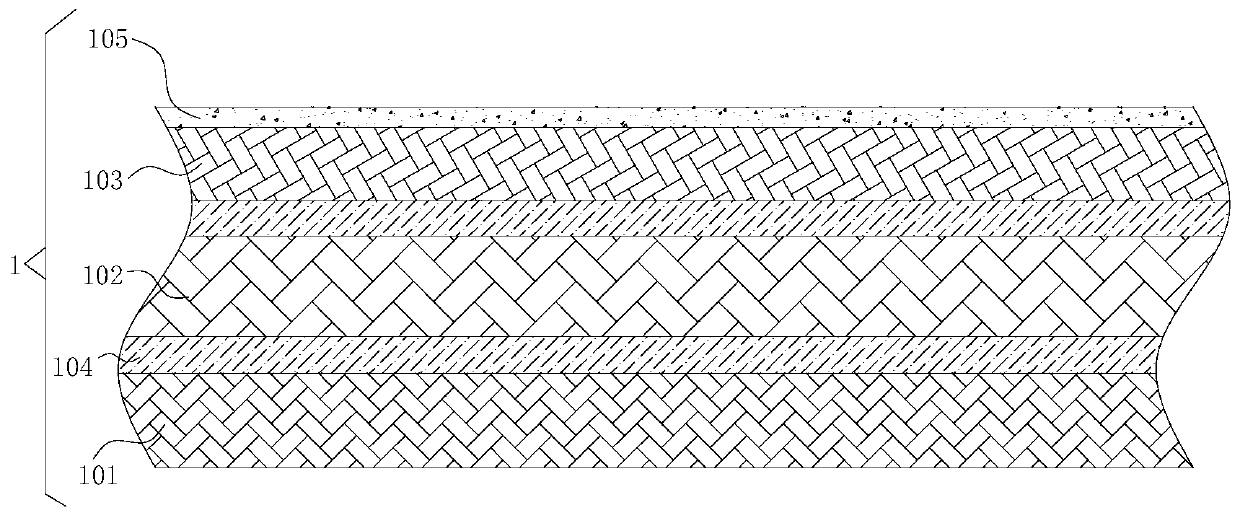

[0035] S1. Use polyester fibers as warp and weft yarns for blending and twisting into yarns, and form the outer fabric 103 fabrics through the weaving process; use nano-silver antibacterial fibers and nano-carbon black fibers for blending, twisting into yarns, and through the weaving process Form an intermediate base material 102; use cotton fibers and polyester fibers as warp and weft threads to blend and twist into yarns, and form an inner layer base material 101 through a weaving process;

[0036] S2. First, evenly coat the bottom of the intermediate base material 102 with the adhesive layer 104, and attach the inner fabric 101 to the bottom of the intermediate base material 102;

[0037] S3. Then the top of the intermediate base material 102 is evenly coated with the adhesive layer 104, and the outer fabric 103 is attached t...

Embodiment approach

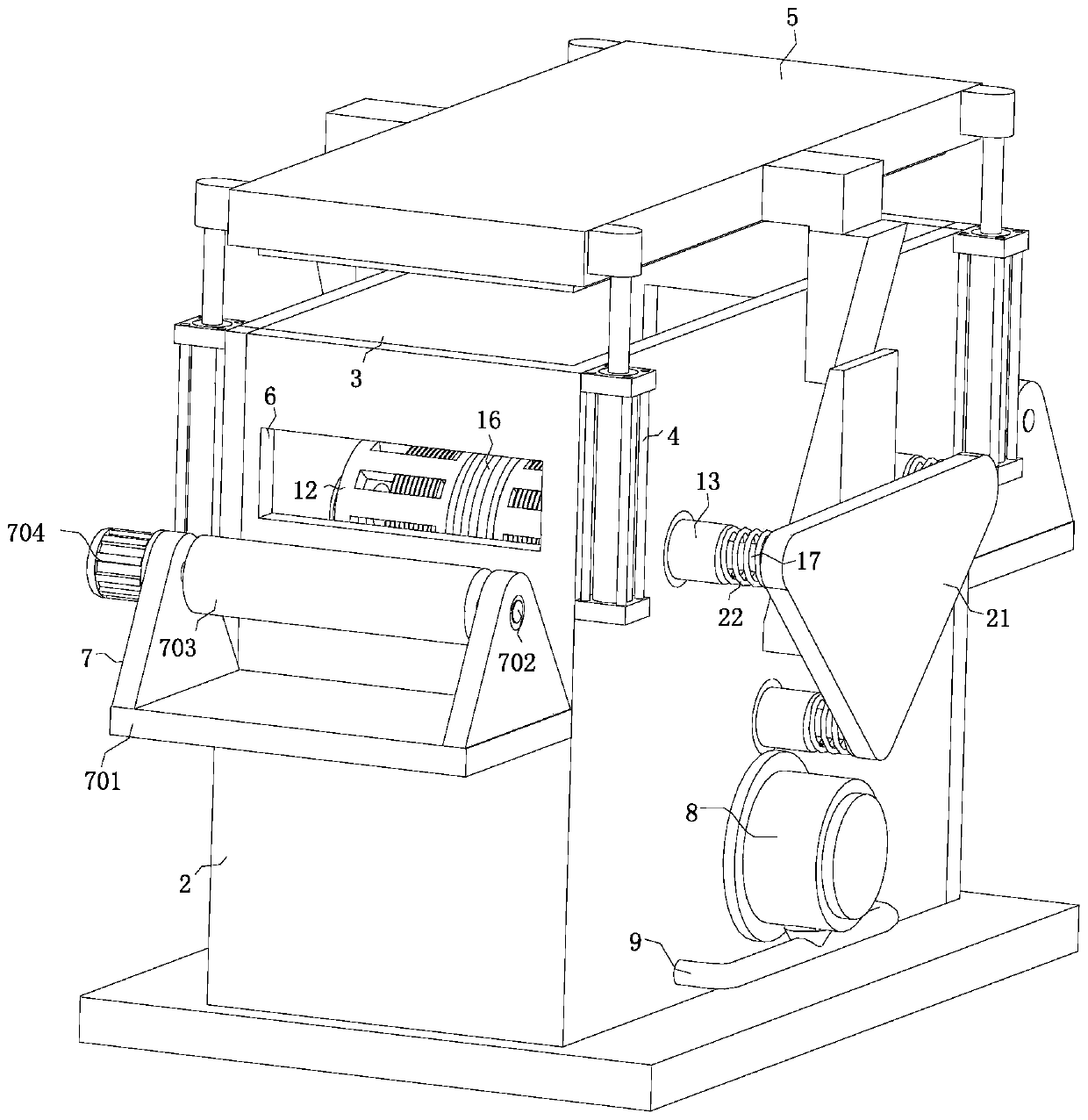

[0040]As an embodiment of the present invention, the cloth driving roller unit 7 includes a driving frame 701; the driving frame 701 is fixedly connected to the surface of the drying box 2 and is located below the cloth inlet and outlet 6; the driving frame 701 The inner wall is rotatably connected with a drive shaft 702; the surface of the drive shaft 702 is fixedly connected with a cloth drive roller 703; one end of the drive shaft 702 passes through the drive frame 701 and is connected with a drive motor 704; during work, the fabric main body 1 Wrapped on the surface of the cloth driving roller 703, and pass through the drying box 2 through the cloth inlet and outlet 6, and then drive and connect with the surface of the cloth driving roller 703 on the other side, and synchronously control the driving motors 704 on both sides through the external controller Synchronously drive the fabric driving roller 703 to drive the fabric main body 1, so that the fabric main body 1 can be...

Embodiment 1

[0045] Embodiment 1: a kind of antistatic antibacterial fabric of the present invention, comprises the raw material of following mass fraction: 0 part of polyester fiber, 25 parts of nano-silver antibacterial fiber, 25 parts of nano-carbon black fiber, 30 parts of cotton fiber, PU white 10 parts of adhesive coating, 10 parts of adhesive;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com