Separated layer water injection string for petroleum exploitation and water injection process thereof

A technology of layered water injection and pipe string, applied in the direction of production of fluid, drill pipe, casing, etc., can solve the problems of high construction operation cost, easy drilling sticking, high processing cost, and achieve the effect of overcoming the short validity period of layering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

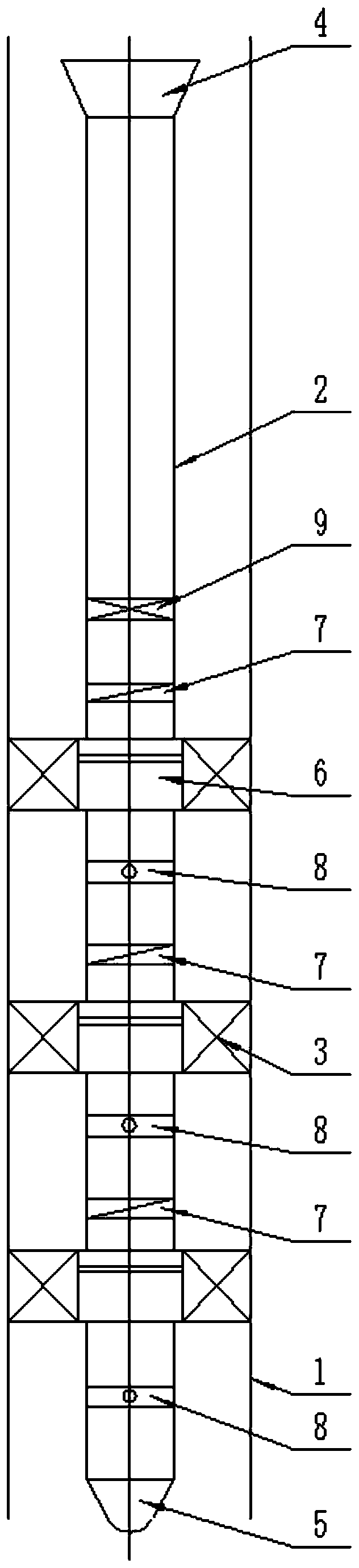

[0030] like Figure 1 to Figure 7 shown,

[0031] A layered water injection pipe string for oil exploitation includes a casing 1 and an oil pipe 2. A plurality of packers 3 are seated in the casing 1 from top to bottom in sequence, and the top of the oil pipe 2 is connected with an oil pipe hanger 4. , the bottom of the oil pipe 2 passes through all the packers 3 in turn and is connected with a round plug 5, an insert seal 6 is provided between the oil pipe 2 and each packer 3, and the oil pipe 2 is in each seal. A hydraulic safety joint 7 is arranged above the separator 3, a water distributor 8 is arranged under each packer 3 of the oil pipe 2, and the upper end of the oil pipe 2 is arranged between the hydraulic safety joint 7 and the oil pipe hanger 4. There are circulating sliding sleeves 9.

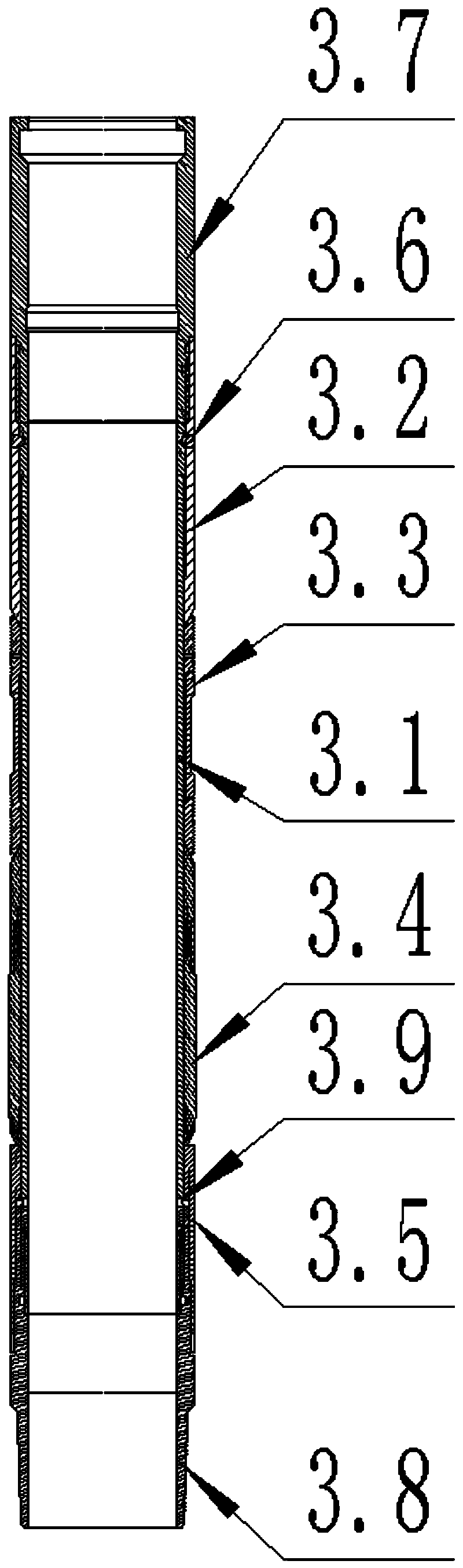

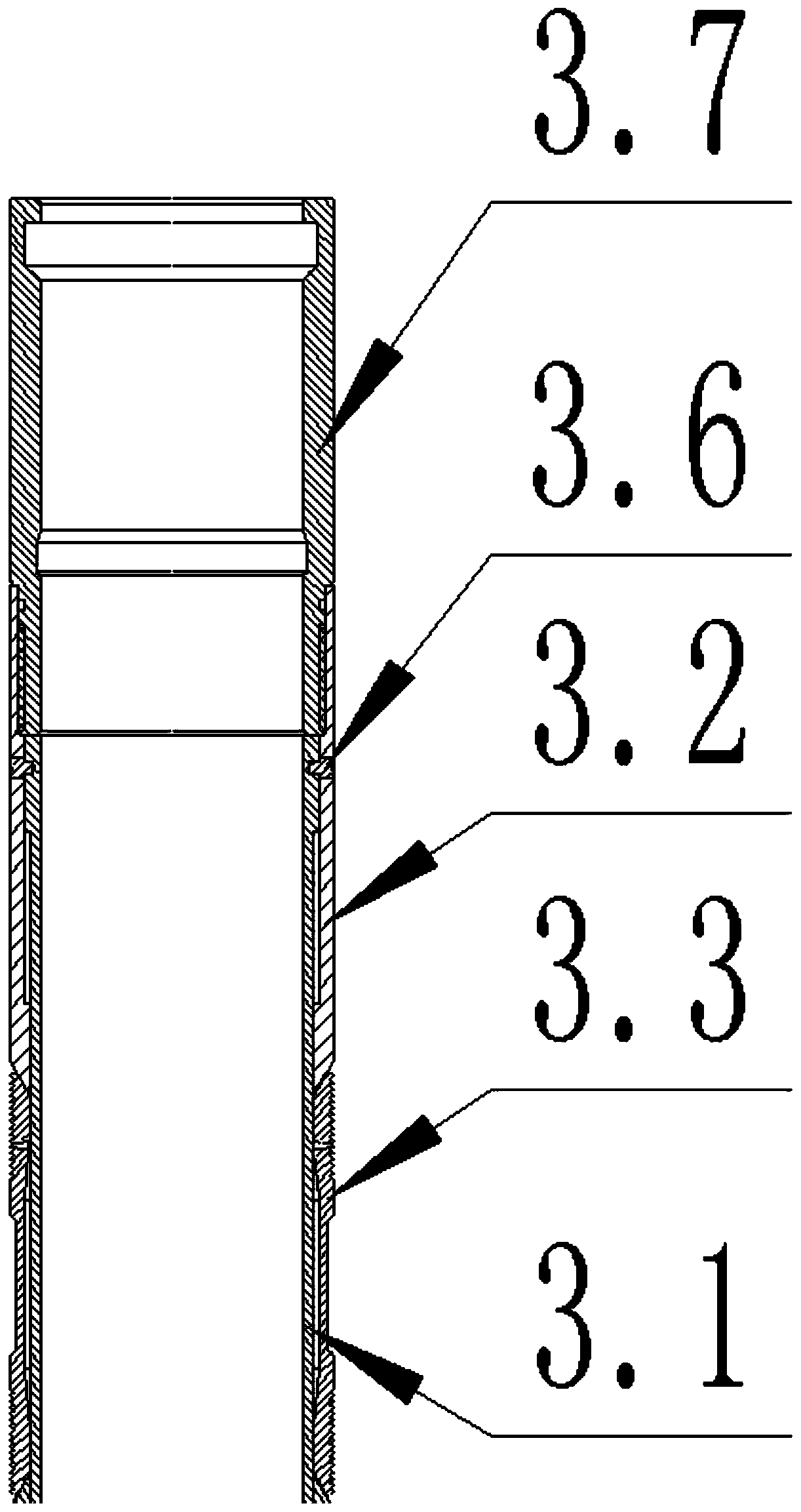

[0032] The packer 3 includes a central pipe 3.1, and outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com