Flexible workshop scheduling optimization method and system with robot transportation

A technology of workshop scheduling and optimization methods, applied in manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as low applicability, slow convergence speed, time-consuming, etc., to minimize completion time, improve convergence, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0035] Example 1

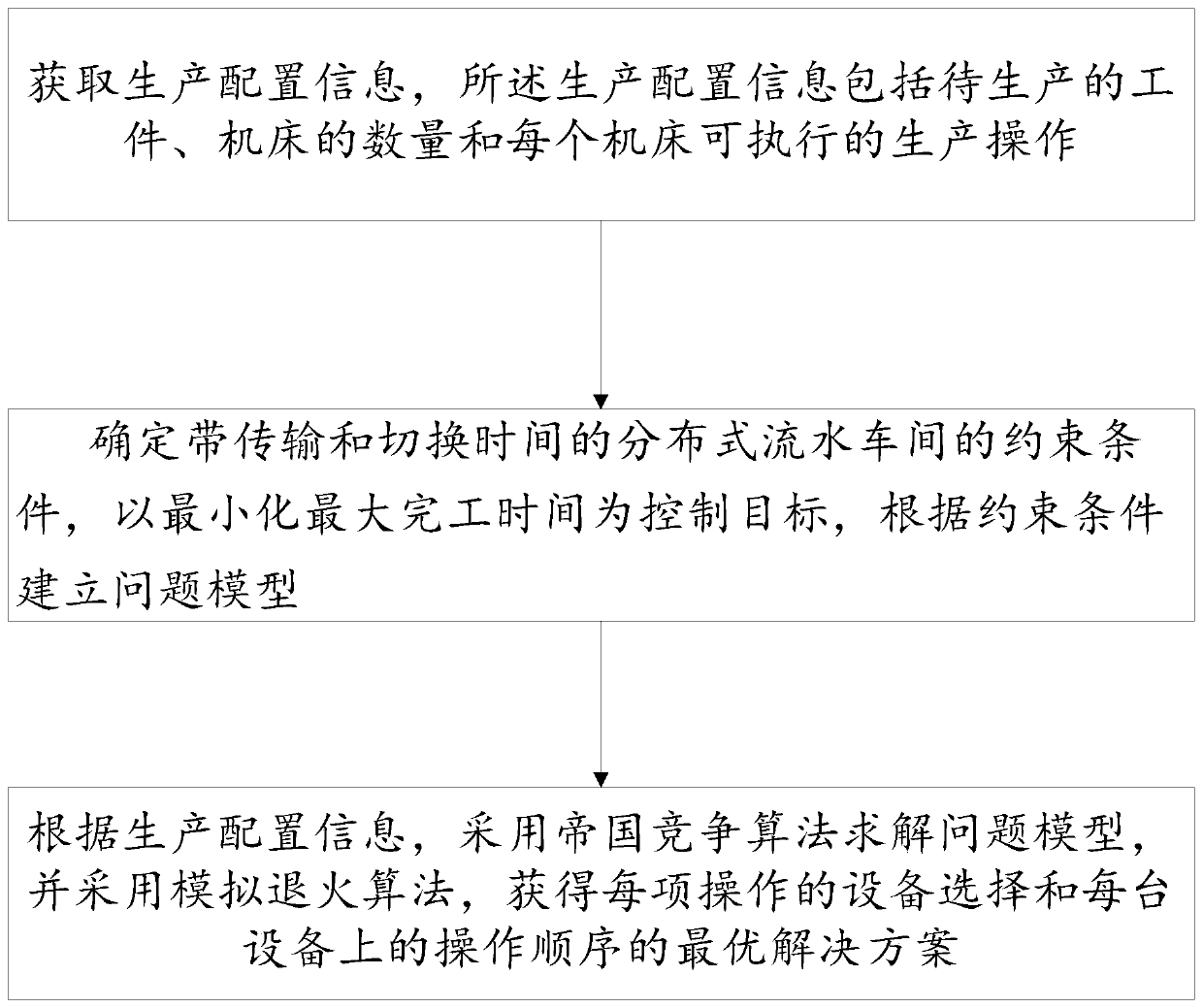

[0036] Among the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a flexible workshop scheduling optimization method with robot transportation includes the following steps:

[0037] Step 1. Obtain production configuration information, where the production configuration information includes the workpieces to be produced, the number of machine tools, and the production operations that each machine tool can perform;

[0038] Step 2. Determine the constraint conditions of the distributed flow shop with transmission and switching time, take minimizing the maximum completion time as the control goal, and establish the problem model according to the constraint conditions;

[0039] Step 3. According to the production configuration information, the imperial competition algorithm is used to solve the problem model, and the simulated annealing algorithm is used to obtain the optimal solution for the selection of equipment for each operation a...

Example Embodiment

[0117] Example 2

[0118] This embodiment provides a flexible workshop scheduling optimization system with robot transportation, including:

[0119] Obtaining module: configured to obtain production configuration information, the production configuration information including the workpieces to be produced, the number of machine tools, and the production operations that each machine tool can perform;

[0120] Problem model establishment module: It is configured to determine the constraint conditions of the distributed flow shop with transmission and switching time, with the control goal of minimizing the maximum completion time, and the problem model is established according to the constraint conditions;

[0121] Solving module: It is configured to solve the problem model by using the imperial competition algorithm according to the production configuration information, and using the simulated annealing algorithm to obtain the optimal solution for the selection of equipment for each oper...

Example Embodiment

[0122] Example 3

[0123] This embodiment provides an electronic device, including a memory, a processor, and computer instructions stored on the memory and running on the processor. When the computer instructions are executed by the processor, the steps described in the method in Embodiment 1 are completed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap