Clamp of aero-engine turbine blade shroud thinning part and machining method thereof

A technology of aero-engines and turbine blades, which is applied in air transportation, metal processing equipment, metal processing machinery parts, etc., can solve problems such as unrealizable and difficult, and achieve the effects of reducing costs, improving production efficiency, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

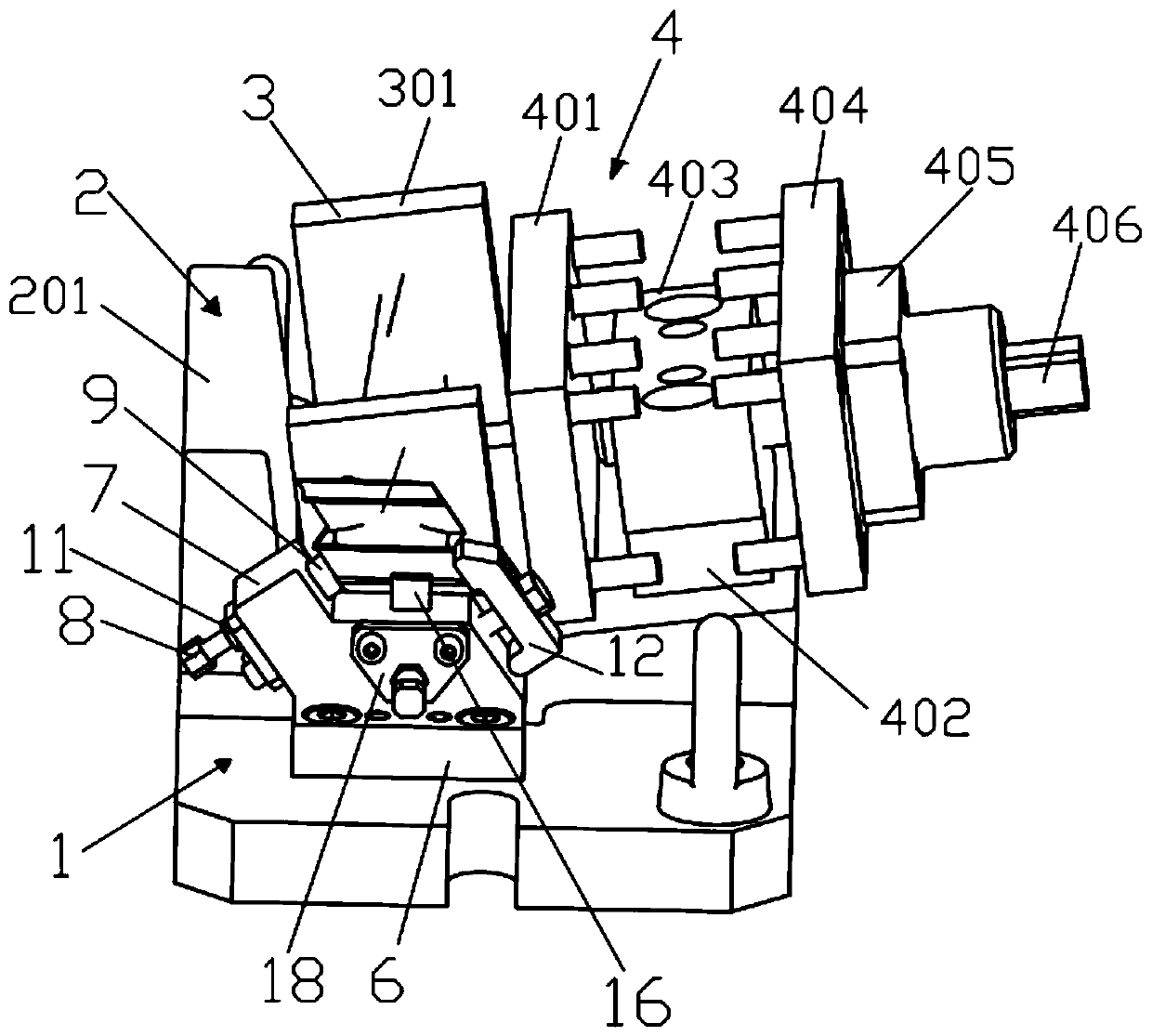

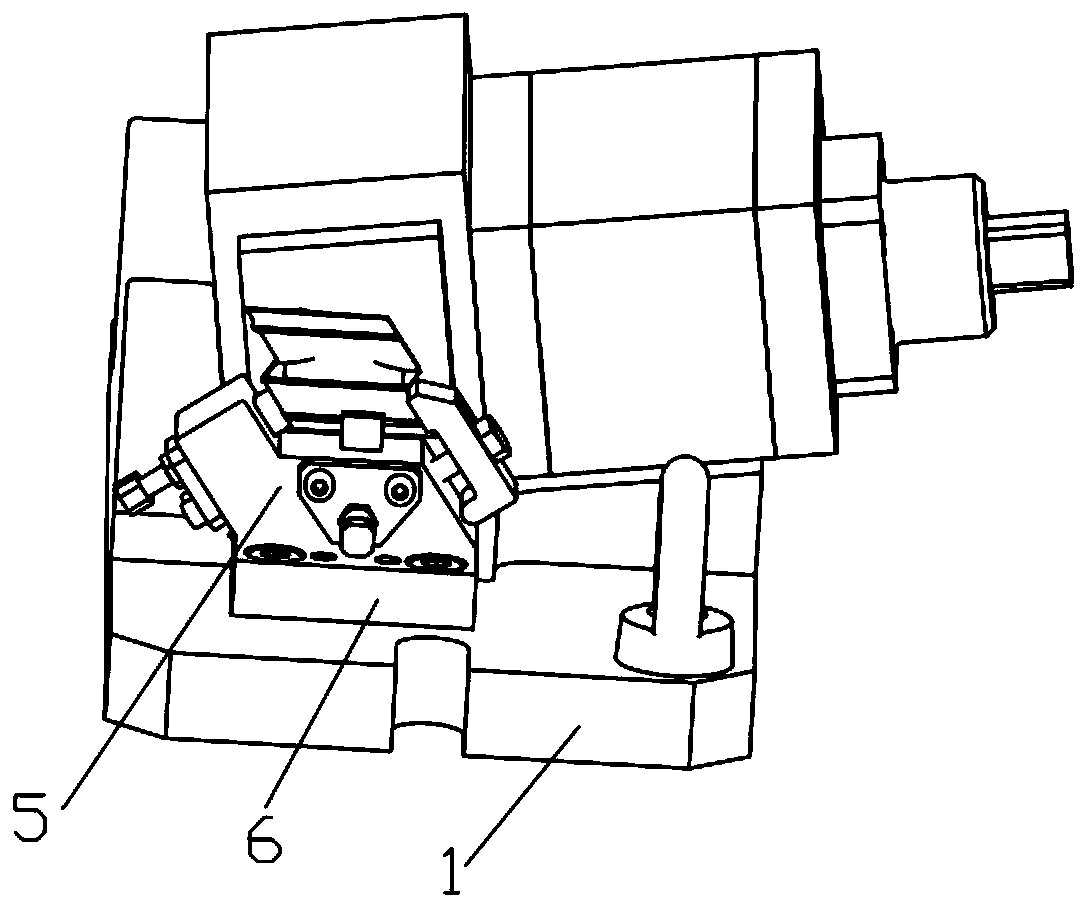

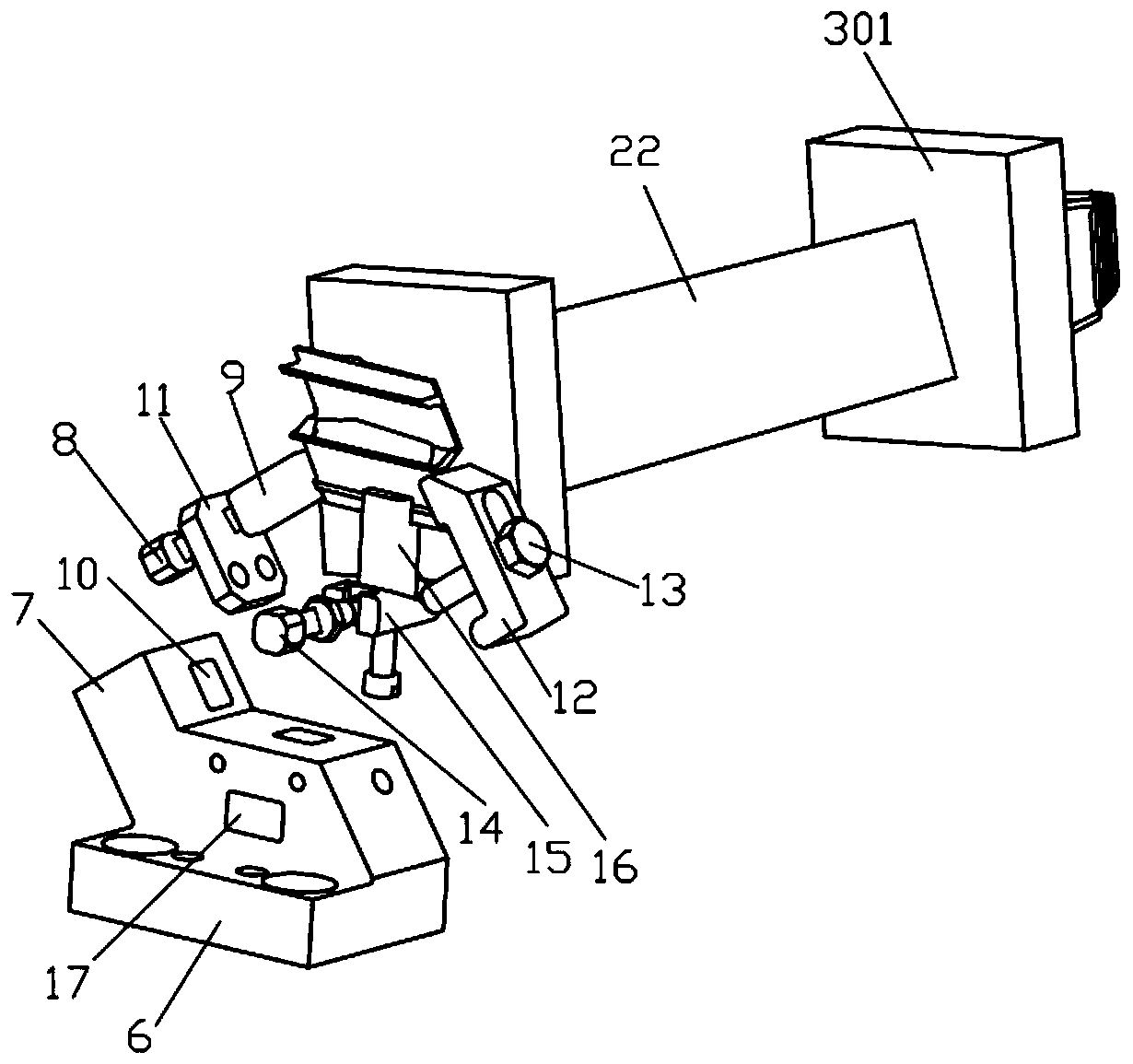

[0041] refer to Figure 1-6 , the present invention provides a technical solution:

[0042] Please refer to Figure 1-2 , a fixture for the thinning part of the turbine blade shroud of an aeroengine, comprising a base 1, a main positioning assembly 2 of a square box on the airfoil profile, a positioning assembly 3 on the back side of the square box, a positioning assembly 4 on the trailing edge surface of the square box, and a positioning assembly 5 for the shroud The positioning assembly 4 on the rear edge surface of the square box is slidably installed on the base 1 and attached to the square box on the surface of the blade body basin, and the positioning assembly 3 on the back side of the square box is installed on the base 1 and used to fix the The root of the blade, the main positioning assembly 2 of the airfoil profile square box is installed on the base 1 and is located in the square box at the back of the blade airfoil, and the blade crown positioning assembly 5 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com