Preparation method of malt syrup prepared from corn

A technology for making malt and syrup, which is applied in the field of preparation of corn malt syrup, which can solve the problems of large water consumption, environmental pollution, and high process cost, and achieve the effects of reducing procurement costs, increasing cost input, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

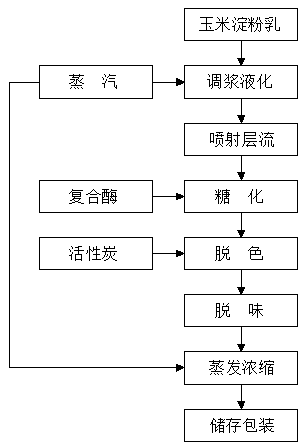

[0018] Such as figure 1 Shown, a kind of preparation method of corn maltose syrup, concrete operation steps are as follows:

[0019] a. Slurry liquefaction: mix the raw material cornstarch with water to make the cornstarch content reach 34%, add high-temperature-resistant amylase under the condition of pH5.6, and then liquefy at 108°C for 3 minutes to obtain a liquefied slurry;

[0020] b. Spray laminar flow: spray the liquefied slurry prepared in step a once at a temperature of 95°C for 90 minutes, and control the DE value to 15%; then continue to carry out secondary spraying at the same temperature for 30 minutes, control The DE value is 16% and the slag is removed and filtered to obtain the spray slurry;

[0021] c. Saccharification: Saccharify the sprayed slurry prepared in step b and the compound glucoamylase at 60°C and pH 4.5 for 4 hours to obtain the saccharified slurry; remove slag after saccharification; the compound glucoamylase is fungal enzyme, β-amylase , pullu...

Embodiment 2

[0026] Such as figure 1 Shown, a kind of preparation method of corn maltose syrup, concrete operation steps are as follows:

[0027] a. Slurry liquefaction: mix the raw material cornstarch with water to make the cornstarch content reach 40%, add high-temperature-resistant amylase under the condition of pH5.8, and then liquefy at 110°C for 5min to obtain the liquefied slurry;

[0028] b. Spray laminar flow: spray the liquefied slurry prepared in step a once at a temperature of 98°C for 120 minutes, and control the DE value to 20%; then continue to carry out secondary spraying at the same temperature for 30 minutes, control The DE value is 22% and the slag is removed and filtered to obtain the spray slurry;

[0029] c. Saccharification: saccharify the jet slurry prepared in step b and the compound glucoamylase at 62°C and pH 6.0 for 120 hours to obtain the saccharification slurry; remove slag after saccharification; the compound glucoamylase is fungal enzyme, β-amylase , pullu...

Embodiment 3

[0034] Such as figure 1 Shown, a kind of preparation method of corn maltose syrup, concrete operation steps are as follows:

[0035] a. Slurry liquefaction: mix the raw material cornstarch with water to reach a cornstarch content of 37%, add high-temperature-resistant amylase under the condition of pH5.7, and then liquefy at 109°C for 4 minutes to obtain a liquefied slurry;

[0036] b. Spray laminar flow: spray the liquefied slurry prepared in step a once at a temperature of 97°C for 100 minutes, and control the DE value to 18%; then continue to carry out secondary spraying at the same temperature for 30 minutes, control The DE value is 19% and the slag is removed and filtered to obtain the spray slurry;

[0037] c. Saccharification: saccharify the jet slurry prepared in step b and the compound glucoamylase at 61°C and pH 5.0 for 60 hours to obtain the saccharification slurry; remove slag after saccharification; the compound glucoamylase is fungal enzyme and β-amylase , pull...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap