Efficient quenching control method for thin-gauge quenched and tempered plates

A control method and thin gauge technology, applied in the direction of heat treatment process control, manufacturing tools, furnace types, etc., can solve the problems of large plate defects and low qualification rate, and achieve the effect of improving quenching efficiency and tempering heat treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In order to make the present invention more clear, a high-efficiency quenching control method for thin-gauge quenched and tempered plates of the present invention will be further described below in conjunction with the accompanying drawings. The specific embodiments described here are only used to explain the present invention and are not intended to limit it. this invention.

[0025] Taking the NM450 high-efficiency quenching plate with a specification of 5mm*3000mm*10000mm as an example, the effective length of the heat treatment furnace is 66m, and the safety interval for continuous production of steel plates is 1.2m. The specific steps of the high-efficiency quenching control method for NM450 are as follows, and the characteristics include:

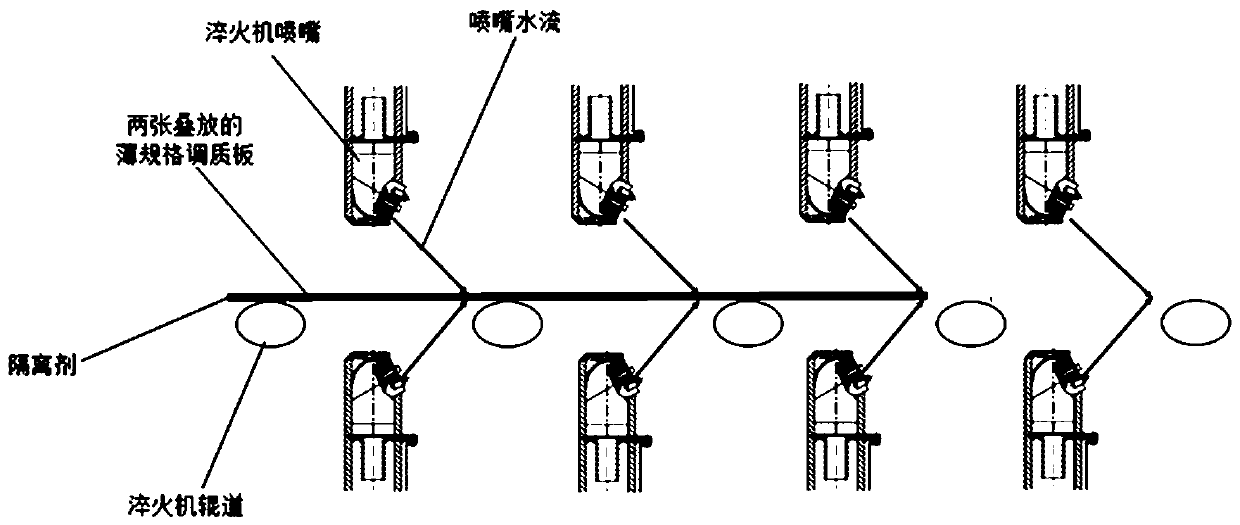

[0026] (1) Lamination: consider two above-mentioned NM450s fused together with release agent in the middle, up and down, and edges together as a 10mm*3000mm*10000mm NM450;

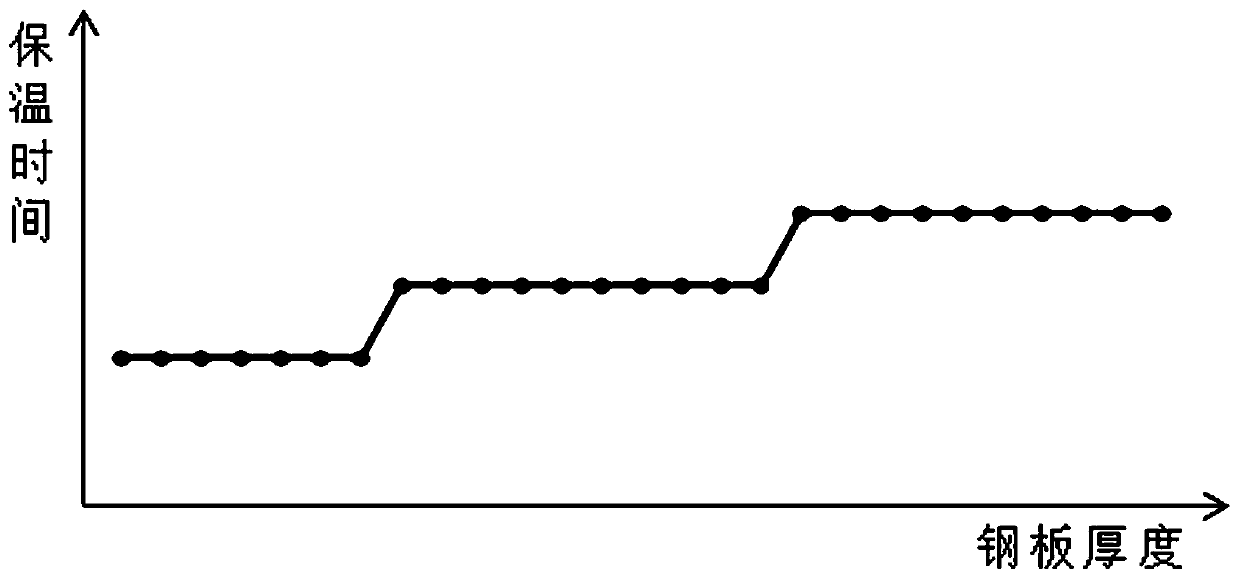

[0027] (2) Set the heating coefficient and furnace ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com