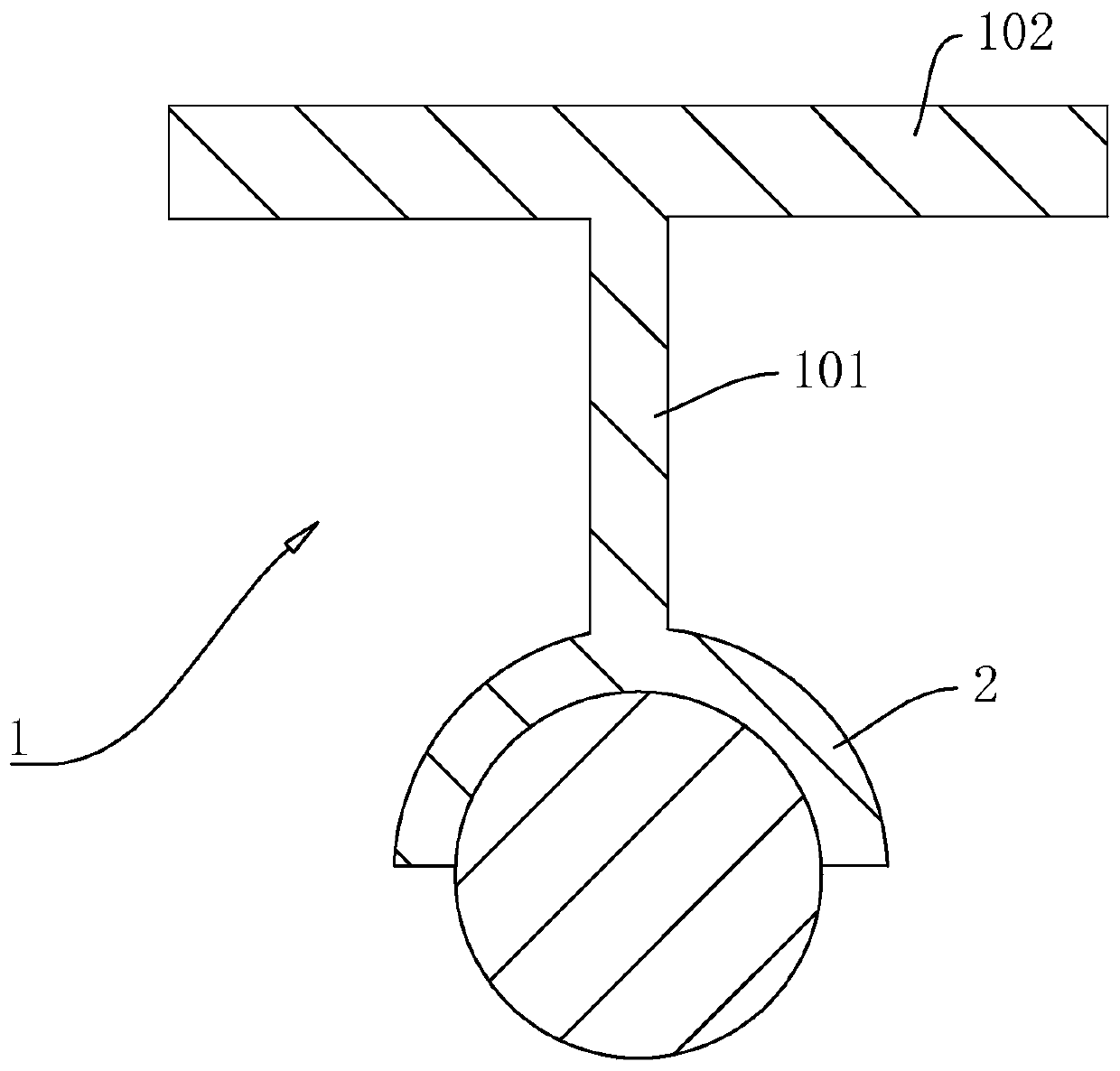

Fine grid and construction method of rotational flow grit chamber

The technology of a swirl grit chamber and construction method is applied in the construction field of fine grids and swirl grit chambers, which can solve the problem of affecting the normal service life of the grit chamber, pit bodies and cracks of different sizes, and lack of solidification on the inner wall Structural and other issues, to improve the overall stability and load strength, reduce gap cracking, and reduce the effect of sieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A construction method of a fine grid and a swirl grit chamber, comprising the following construction steps:

[0041] S100, selecting the site of the foundation pit, firstly selecting at least two different pieces of land, randomly sampling at least five land samples in different orientations from each piece of land through a soil sampling instrument, and submitting them for inspection. The degree of porosity of the soil is determined through soil sample analysis, and then the foundation selected for the excavation of the foundation pit is selected according to the soil quality.

[0042] After the foundation is determined, according to the pre-planned size, calibrate the excavation range on the selected foundation, and the calibrated range must be controlled within the planned size and must not exceed the size. The boundary line of the calibrated range can be demarcated by color steel plates. Use a forklift to dig out at least 30 cm of surface miscellaneous fill on the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com