Workpiece flanging analysis and control method for separating radial and axial electromagnetic forces

An analysis method and electromagnetic force technology, which is applied in the field of metal workpiece forming control, can solve the problems that it is difficult to optimize the design of the electromagnetic flanging device of the plate, and the contribution of the radial electromagnetic force flanging cannot be separated, so as to improve the quality of the workpiece flanging , the effect of optimizing the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

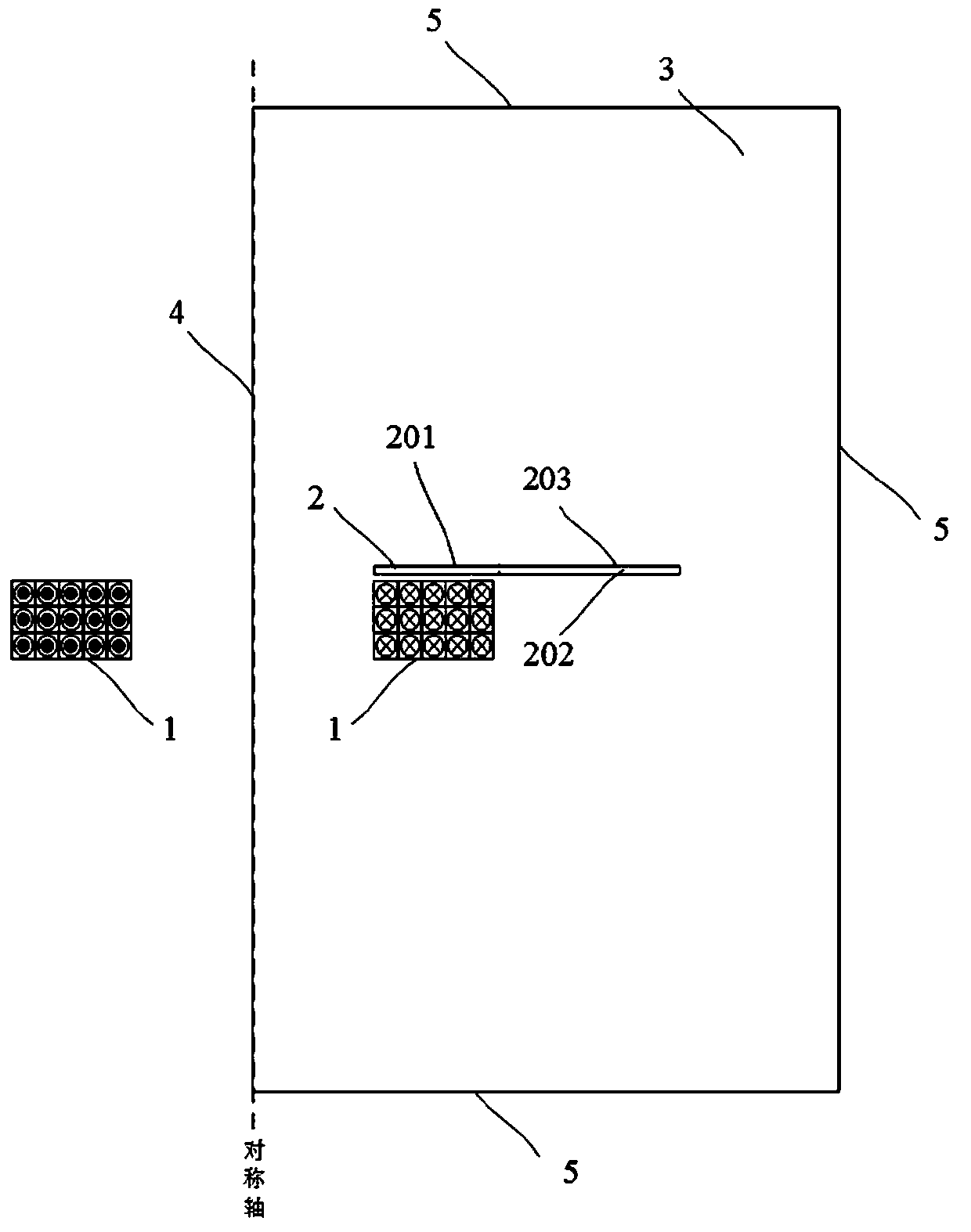

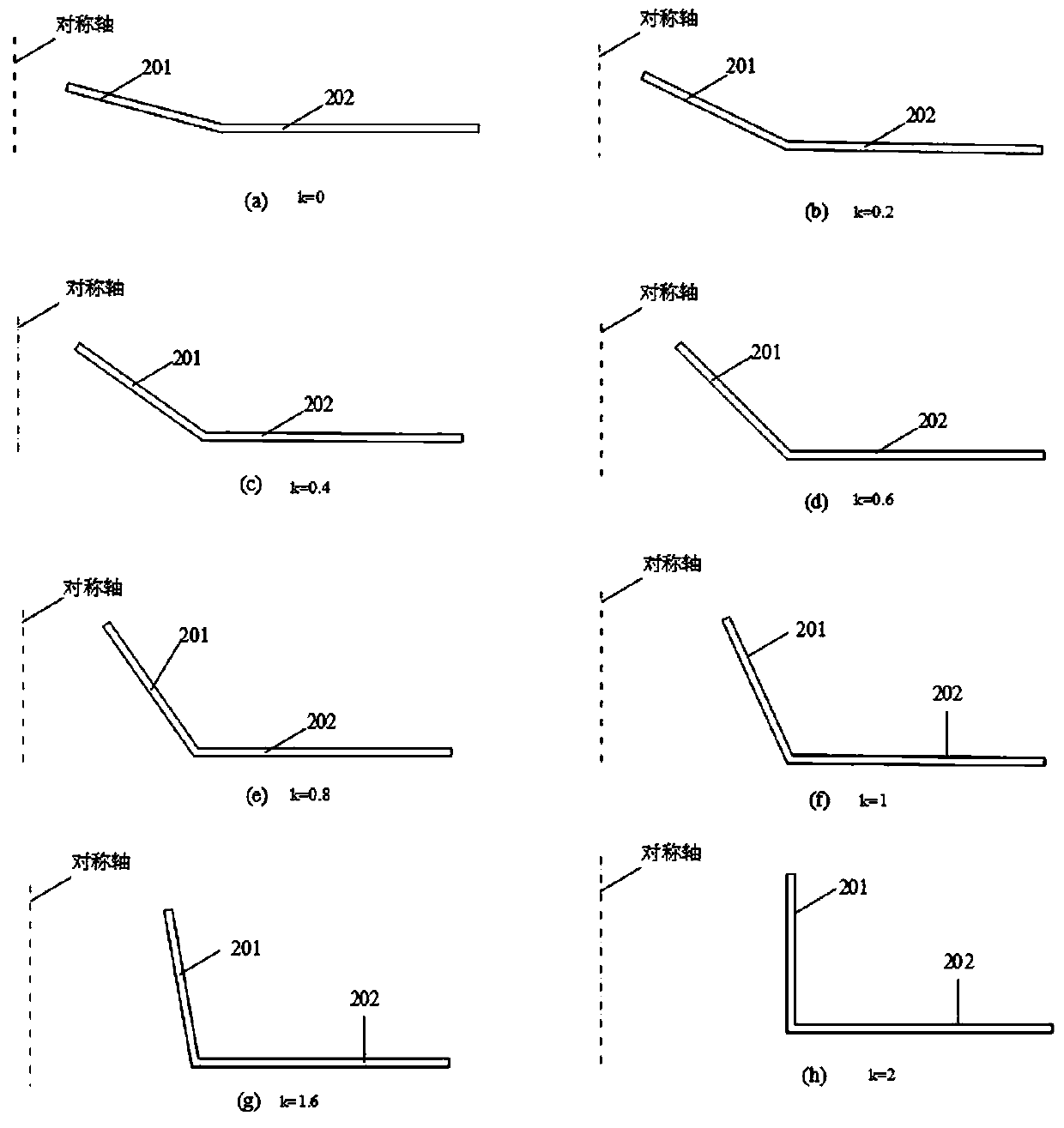

[0033] Such as Figure 1-3 As shown, the panel flanging analysis method that separates the radial and axial electromagnetic forces establishes an electromagnetic flanging model that includes the panel to be flanged, the drive coil, and the air domain. The model includes an electromagnetic module and a structural module. The electromagnetic module is used for Simulation calculation of radial electromagnetic force distribution Fr and axial electromagnetic force distribution Fz, the structure module is used to simulate and calculate the flanging effect of the panel, and the flanging analysis method of the panel includes the following steps,

[0034] Step 1: Use finite element software to establish the electromagnetic flanging model of the panel;

[0035] Step 2: Establish an electromagnetic module for the electromagnetic flanging model of the plate, and use the electromagnetic module to obtain the electromagnetic force distribution;

[0036] Step 2.1: Build an electromagnetic mo...

Embodiment 2

[0049] Such as figure 1and Figure 4 As shown, based on the simulation method of pipe flanging analysis of separated axial electromagnetic force, an electromagnetic flanging model including the pipe to be flanged, the driving coil, and the air domain is established. The model includes an electromagnetic module and a structural module, and the electromagnetic module is used for simulation calculations Radial electromagnetic force distribution Fr and axial electromagnetic force distribution Fz, the structure module is used to simulate and calculate the flanging effect of pipe fittings, and the flanging analysis method of pipe fittings includes the following steps,

[0050] Step 1: Use finite element software to establish the electromagnetic flanging model of pipe fittings;

[0051] Step 2: Establish an electromagnetic module for the electromagnetic flanging model of the pipe fitting, and use the electromagnetic module to obtain the electromagnetic force distribution;

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com