Synthesis method of amino-anisole compound

An aminoanisole and a synthesis method technology, applied in the field of catalysis, can solve the problems of easy agglomeration, great environmental hazards, easy to be eluted, etc., and achieve the effects of being suitable for storage and transportation, good catalytic performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The invention provides a method for synthesizing aminoanisole compounds, comprising: using a carbon-coated nickel nanocomposite material containing alkali metals as a catalyst, and catalyzing nitroanisole compounds for hydrogenation reduction reaction under a hydrogen atmosphere ; The chemical reaction equation is illustrated as follows,

[0057]

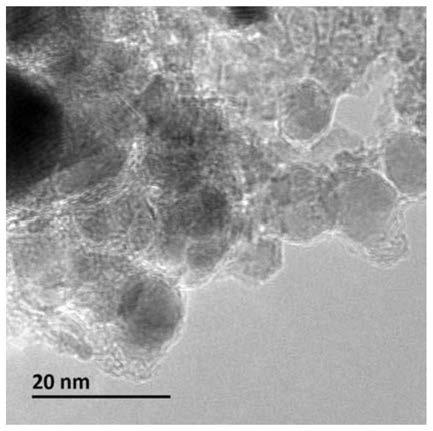

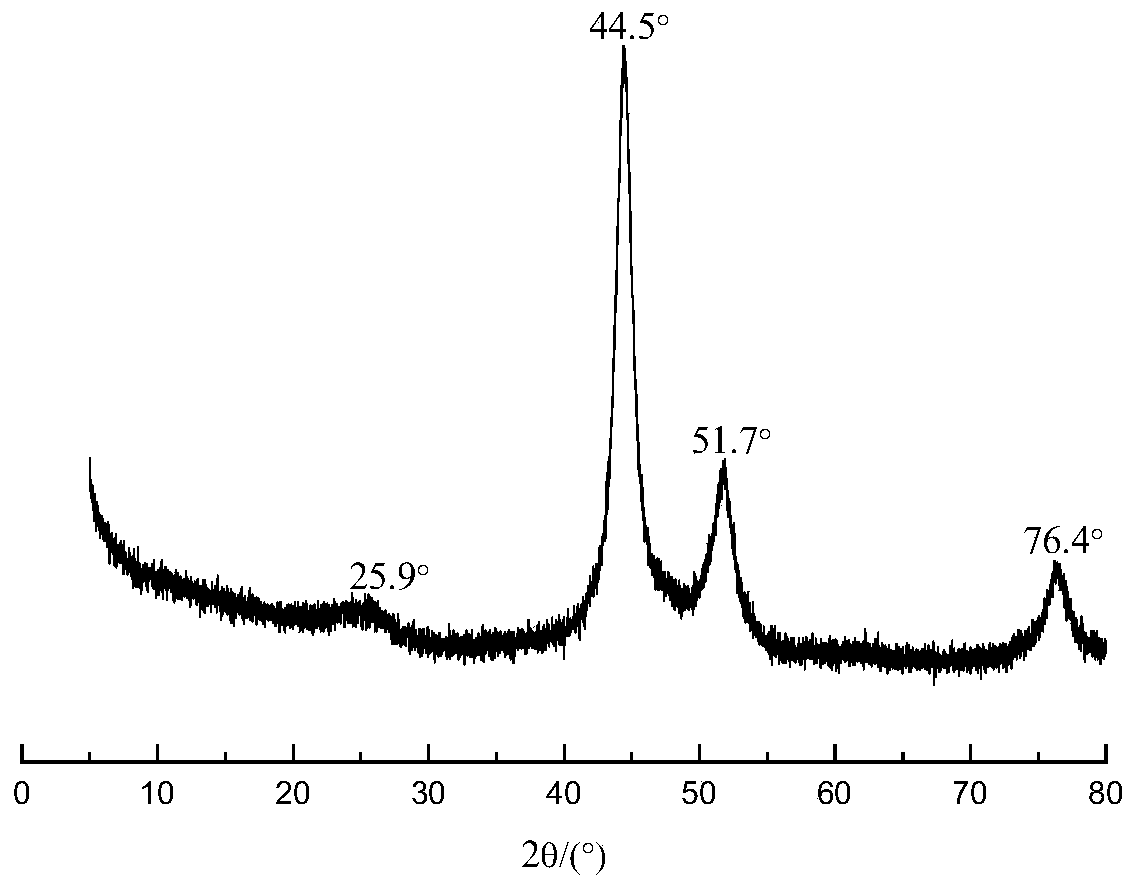

[0058] Wherein, the nanocomposite material has a core-shell structure with a shell and an inner core, the shell is a graphitized carbon layer containing alkali metal and oxygen, and the inner core is nickel nanoparticles.

[0059] In some embodiments, the benzene ring of the nitroanisole compound also contains a substituent, and the substituent R is selected from C 1-20 One or more of the alkyl, cycloalkyl and aryl groups, the above-mentioned substitutions can be mono-substituted or multi-substituted, such as p-nitroanisole, m-nitroanisole or 3-methyl -4-Nitroanisole.

[0060] In some embodiments, the catalyst accounts f...

preparation example 1

[0099] (1) Weigh 10g of nickel acetate and 10g of citric acid into a beaker containing 30mL of deionized water, stir at 70°C to obtain a homogeneous solution, continue heating and evaporate to dryness, and obtain a solid precursor.

[0100] (2) Place the solid precursor obtained in step (1) in a porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed nitrogen gas with a flow rate of 100mL / min, and set the temperature at a rate of 5°C / min. Raise the temperature to 650°C, stop the heating after keeping the temperature for 2 hours, and cool to room temperature under a nitrogen atmosphere to obtain a carbon-coated nickel material.

[0101] (3) Weigh 2 g of the material obtained in step (2), add 4 ml of an aqueous solution containing 0.1538 potassium bicarbonate, stir at room temperature for 24 hours, and dry to obtain a potassium-containing carbon-coated transition nickel material.

[0102] (4) Place the material obtained in step (3...

preparation example 2

[0108] (1) Weigh 10g of nickel acetate and 20g of citric acid into a beaker containing 50mL of deionized water, stir at 80°C to obtain a homogeneous solution, continue heating and evaporate to dryness, and obtain a solid precursor.

[0109] (2) Place the solid precursor obtained in step (1) in a porcelain boat, then place the porcelain boat in the constant temperature zone of the tube furnace, feed in nitrogen gas with a flow rate of 150mL / min, and heat at a rate of 5°C / min. Raise the temperature to 600°C, stop heating after keeping the temperature for 2 hours, and cool to room temperature under a nitrogen atmosphere to obtain a carbon-coated nickel material.

[0110] (3) Weigh 2 g of the material obtained in step (2), add 15 mL of 1M KOH aqueous solution, stir at room temperature for 24 h, filter, and finally dry at 120° C. to obtain a potassium-containing carbon-coated nickel material.

[0111] (4) The dried material obtained in step (3) is placed in a porcelain boat, and th...

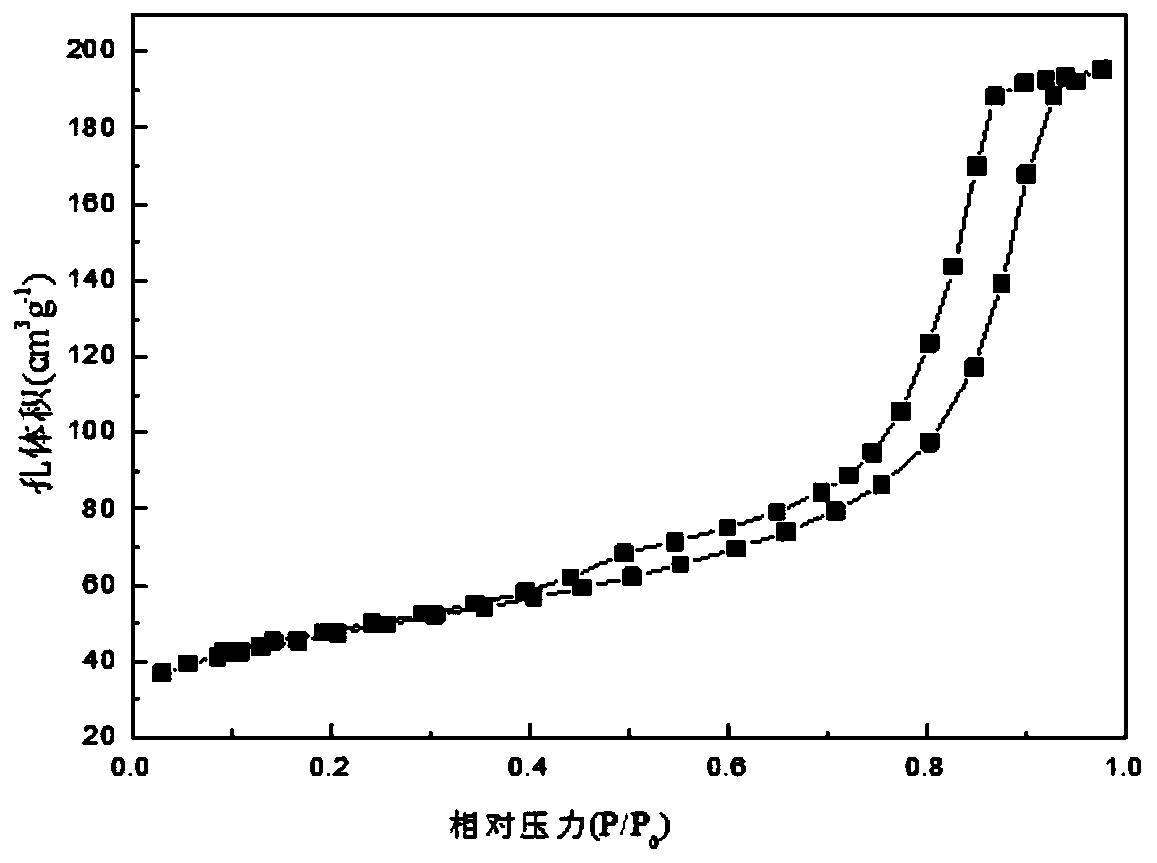

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com