Method for correcting influence quantity of heat supply and steam extraction on sliding pressure operation of steam turbine

A sliding pressure operation and steam turbine technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as difficulty in determining the optimal operating curve of sliding pressure, large manpower and material resources, and test accuracy affected by heat supply and steam extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

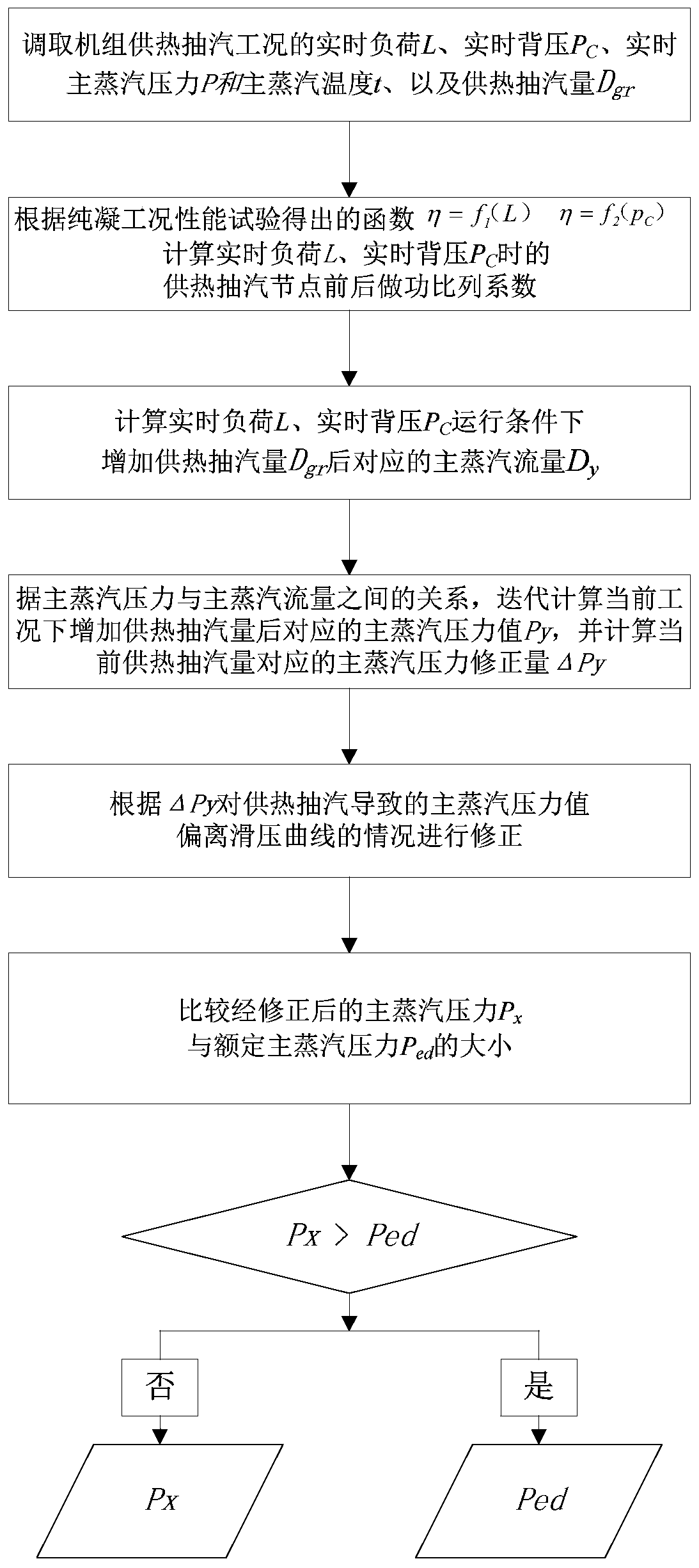

[0058] This embodiment adopts the correction method of the present invention for the influence of heat extraction on steam turbine sliding pressure operation. The steam turbine includes N stage groups before the heat supply and extraction node and M stage groups after the steam extraction node. The method includes:

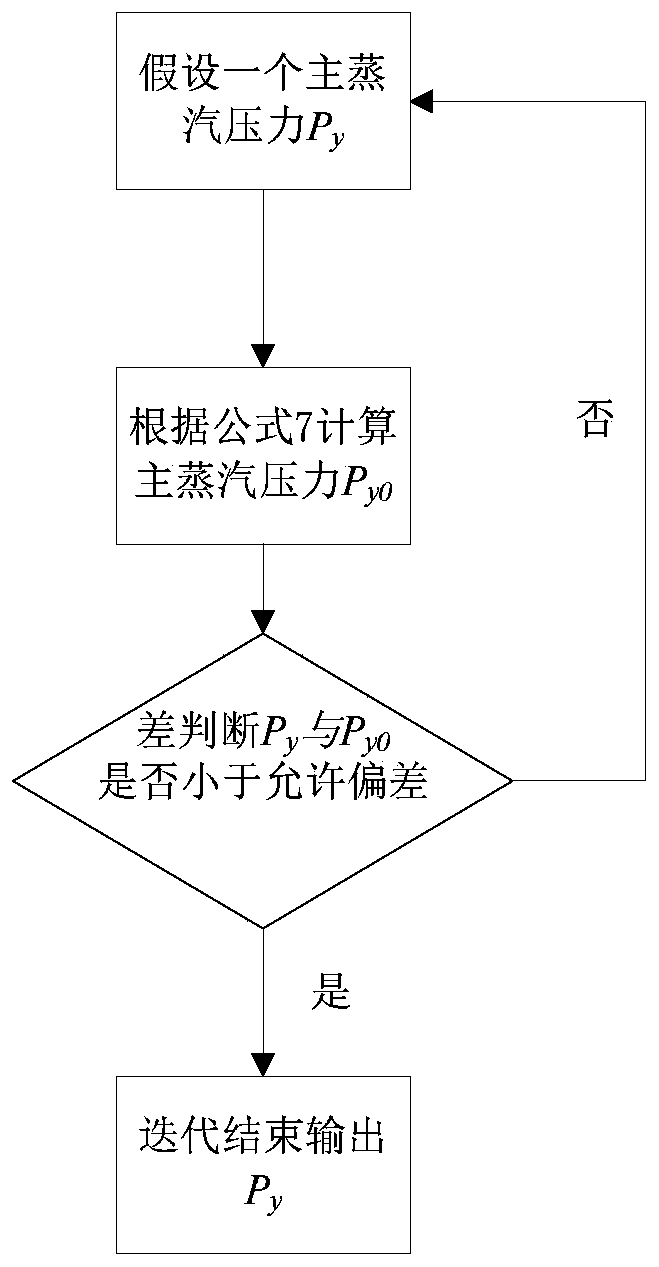

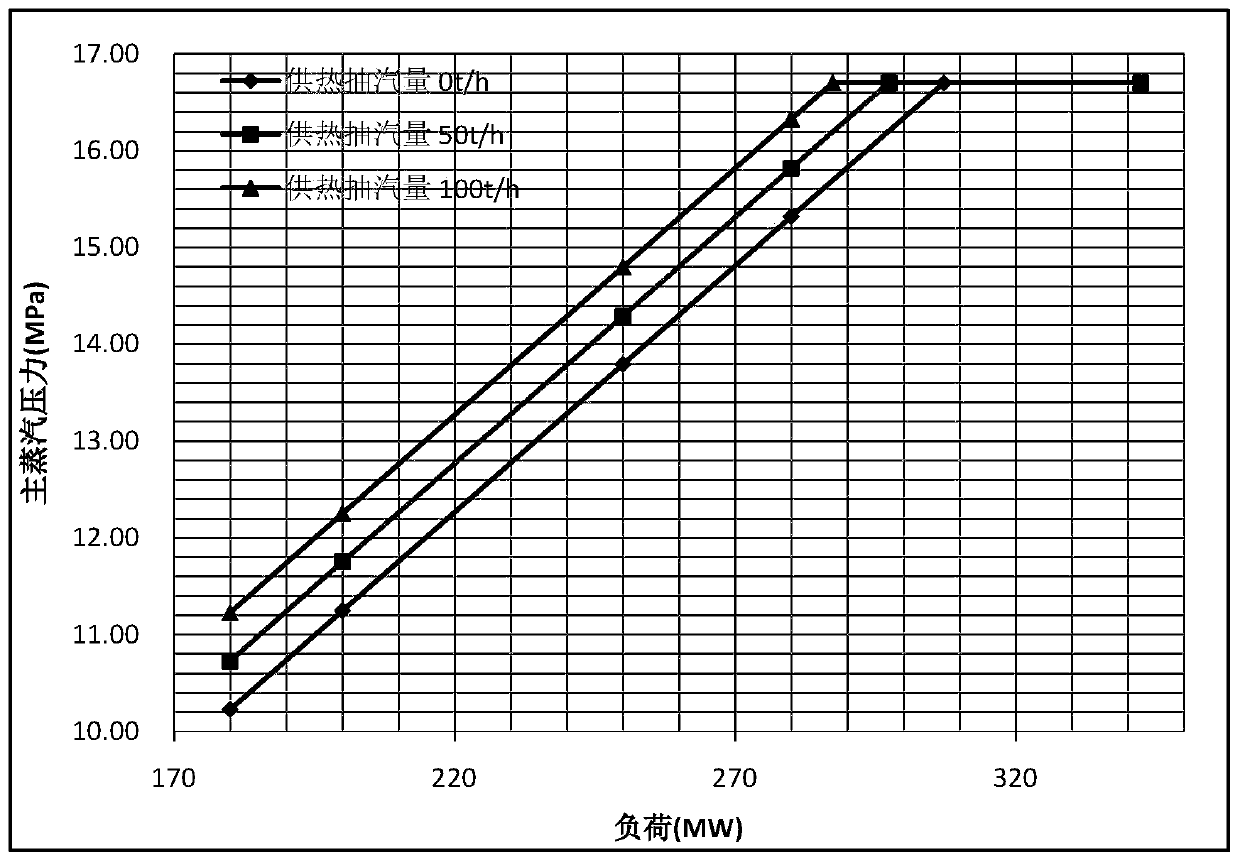

[0059] 1) The thermal performance tests of steam turbines with different loads are carried out under pure condensing conditions to obtain test data corresponding to 4 test load points. In this embodiment, the test load points are 100% rated load, 80% rated load, 65% rated load and 50% rated load Rated load. In the thermal performance test of steam turbines with different loads, the main steam pressure is P according to the test back pressure C0 Optimal sliding pressure curve P=f for pure condensing condition 3 (L, P C0 ) setting, the test back pressure P of the steam turbine can be adjusted by adjusting the amount of circulating cooling water or vacuum leakage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com