A kind of lithium manganate battery material and preparation method thereof

A lithium manganese oxide battery and manganese source technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor high temperature cycle performance, aggravated Jahn-Teller effect, surface structure damage, etc., to improve high temperature resistance , Improve long-term cycle performance and avoid structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

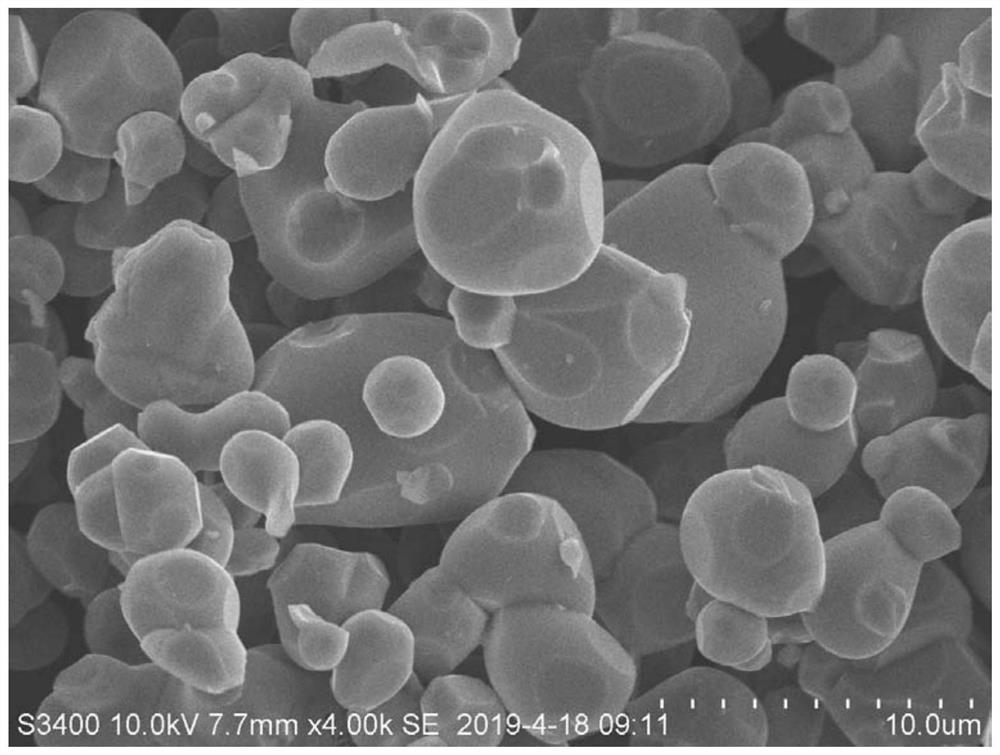

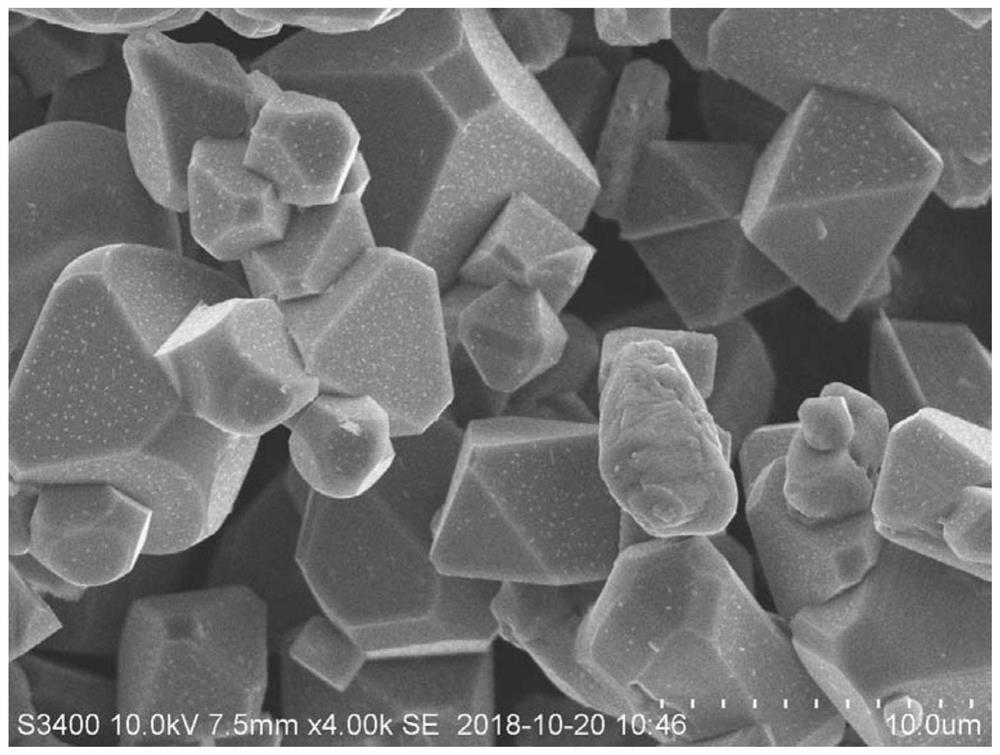

Image

Examples

preparation example Construction

[0032] The present invention provides a kind of preparation method of lithium manganate battery material, and described method comprises the following steps:

[0033] (1) The manganese source compound, lithium source compound, M source compound and L source compound are mixed and then sintered for the first time to obtain Li x mn 2-a-b m a L b o 4 material, the M source compound is at least one of lithium compound, chromium compound, zirconium compound, magnesium compound, niobium compound and boron compound, and the L source compound is cobalt compound, nickel compound, aluminum compound, titanium compound, lanthanum compound At least one of compound and yttrium compound, M is the element code in the M source compound, L is the element code in the L source compound, wherein, 1.00≤x≤1.20, 0.001≤a≤0.010, 0.04≤b≤0.10, The first sintering temperature is 850-1050°C, and the first-time sintering time is 6-20 hours;

[0034] (2) the Li obtained in step (1) x mn 2-a-b m a L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com