Carbon fiber bar and manufacturing method thereof

A technology of carbon fiber rods and manufacturing methods, which is applied in the field of carbon fiber rods, can solve problems such as low torsional strength, achieve the effects of reducing process costs, enhancing space adaptability, and improving torsional strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention is not limited to the embodiments described below. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other, and the technical idea of the present invention can be combined with other known technologies or other technologies that are the same as those known technologies implement.

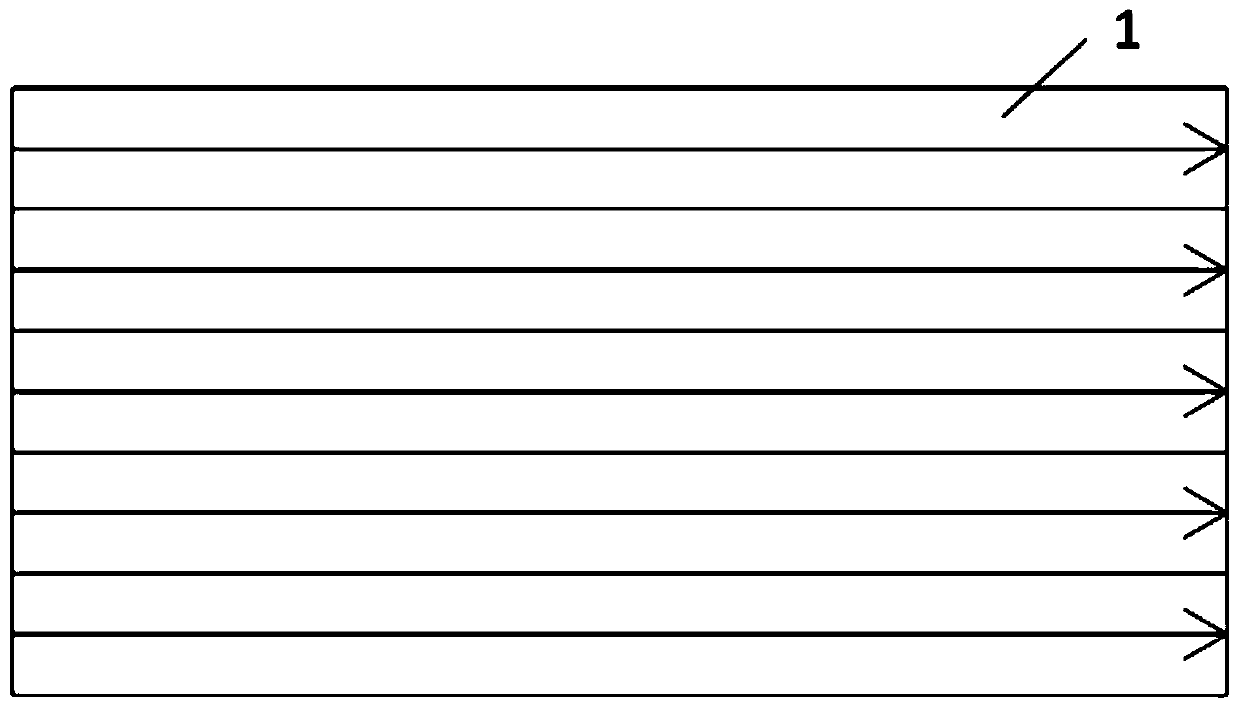

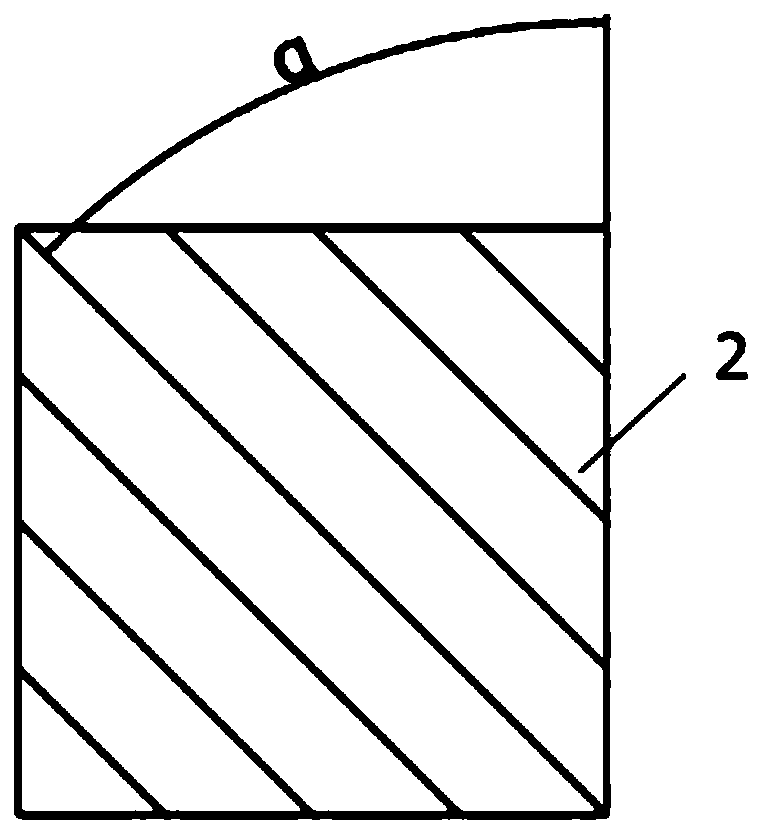

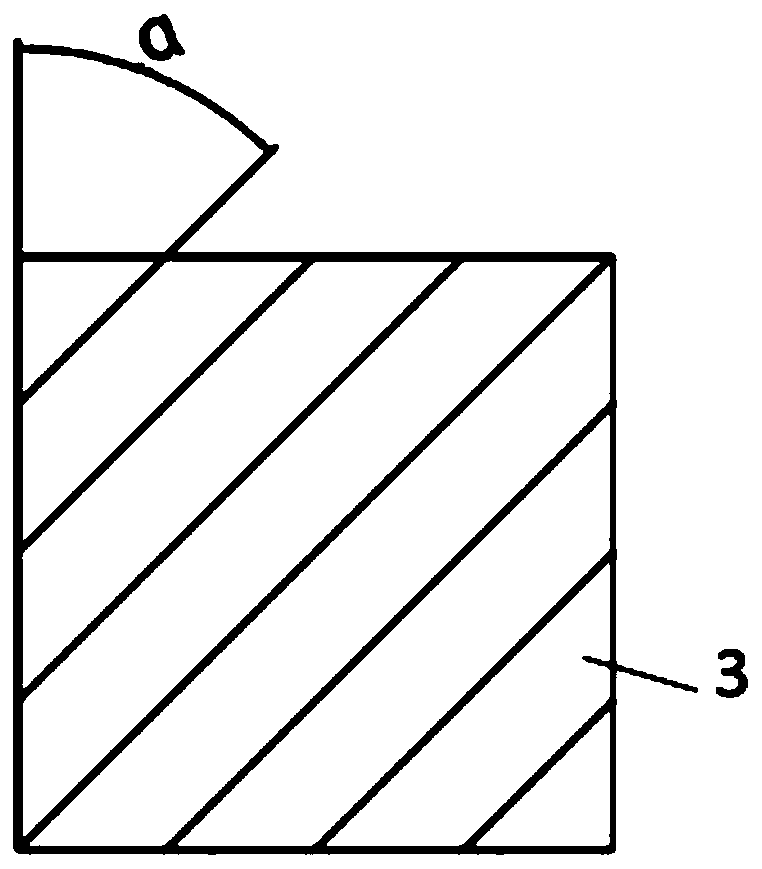

[0030] The carbon fiber obtained by the conventional process is a carbon fiber cloth with a single angular direction. The structure is as follows: figure 1 As shown, when manufacturing the carbon fiber rod provided by the present invention, the carbon fiber cloth 1 arranged in a single angular direction is prepreg treated with a curing agent, so as to facilitate lamination and compression of two carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com