Squeezing and filtering device for rapeseed oil production

A technology for pressing and filtering rapeseed oil, which is applied in the production of fat oil/fat, presses, and fat production. The effect of reducing oil content and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

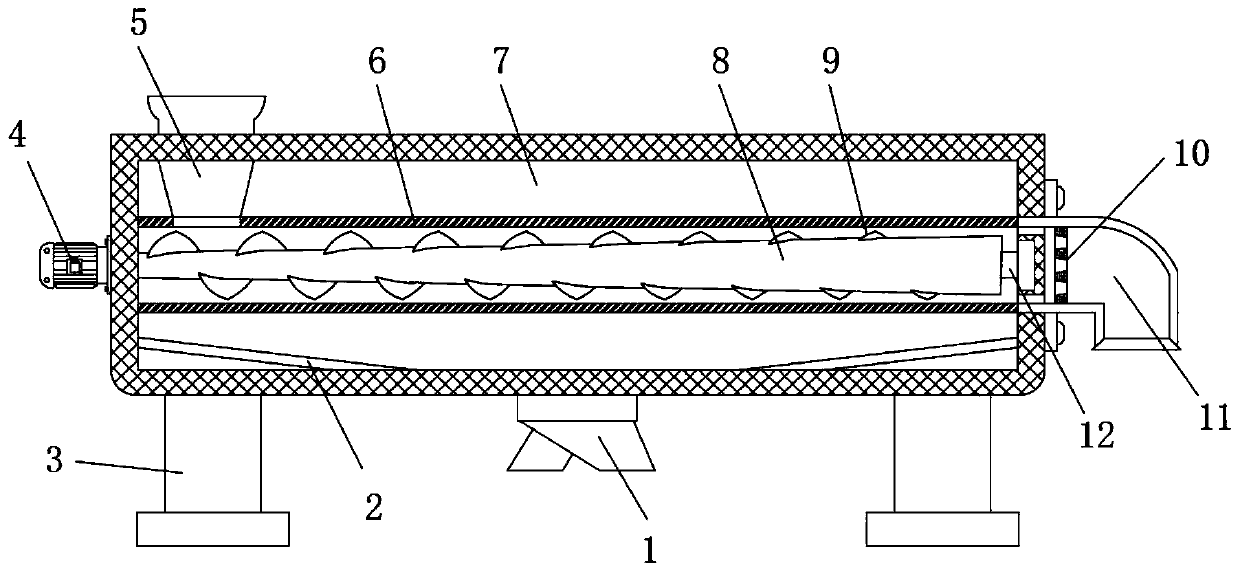

[0023] The present embodiment provides the concrete structure of a kind of rapeseed oil production press filter device, as Figure 1-3 As shown, it includes a device main body 7 adopting a cylindrical structure and an oil extraction cage 6 arranged inside the device body 7 for oil extraction. The oil extraction cage 6 adopts a hollow cylindrical mesh structure, and the oil extraction cage 6 is arranged along the horizontal direction. Through the main body 7 of the device, the inside of the main body 7 is located at the center of the oil press cage 6, and an oil extraction roller 8 is installed through it. There are several sets of screw blades 9 for pushing the extruded material;

[0024] One end of the device main body 7 is equipped with a motor 4 , the output shaft of the motor 4 extends to the inside of the device main body 7 and is connected with one end of the oil extraction roller 8 , and the other end of the device main body 7 is provided with a discharge hopper 11 .

...

Embodiment 2

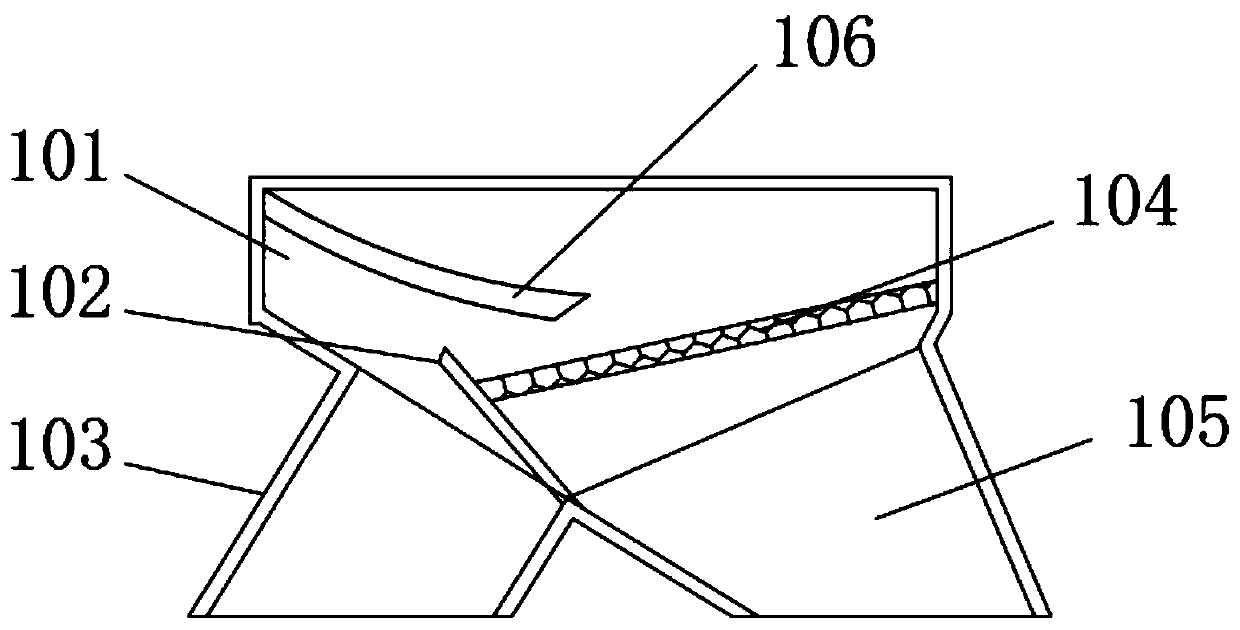

[0031] The present embodiment provides the concrete structure of a kind of rapeseed oil production press filter device, as Figure 1-2 As shown, the center of the bottom of the main body 7 of the device is provided with an oil filter device 1 for filtering the squeezed oil. The oil filter device 1 includes a main pipe 101, a slag pipe 103 arranged under the main pipe 101 for slag discharge, and a slag pipe for slag discharge. Oil tubing 105.

[0032] The slag pipe 103 and the oil pipe 105 are respectively located on both sides below the main pipe 101, and an inclined baffle plate 102 with an inclined structure is arranged above the slag pipe 103 and the oil pipe 105, and a filter plate 104 is arranged above the oil pipe 105, and the filter plate 104 One end of the second diversion plate 106 is lapped on the inclined baffle plate 102, and the inside of the main pipe 101 is also provided with a second diversion plate 106.

[0033] By adopting the above technical solutions:

[...

Embodiment 3

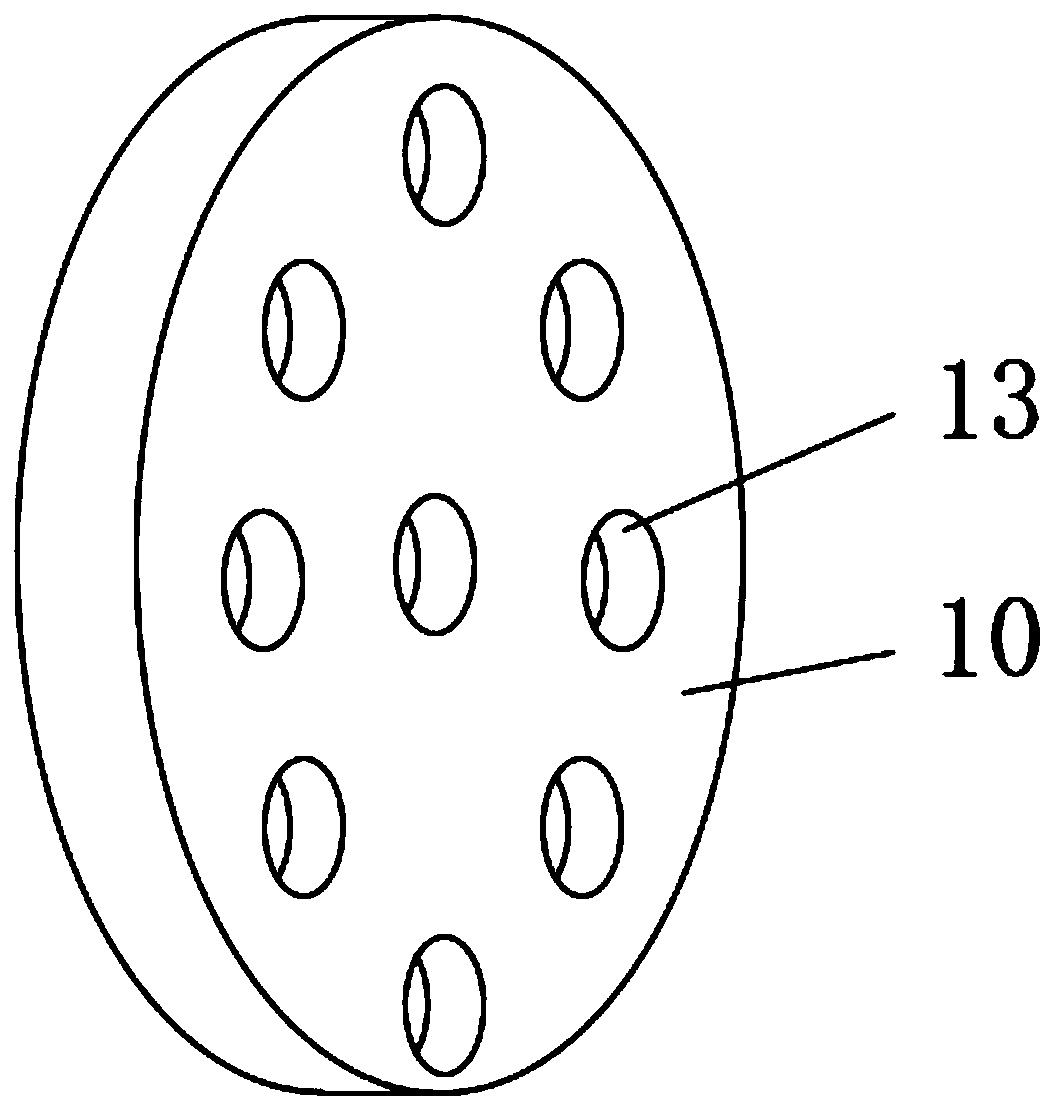

[0038] The present embodiment provides the concrete structure of a kind of rapeseed oil production press filter device, as figure 1 and image 3 As shown, there is an oil residue pressing plate 10 inside the discharge hopper 11, and several slag discharge holes 13 are equally spaced on the surface of the oil residue pressure plate 10, and the slag discharge holes 13 adopt a tapered structure whose diameter gradually decreases from the inside to the outside.

[0039] By adopting the above technical solutions:

[0040] The oil residue pressing plate 10 is set so that the oil residue entering the inside of the discharge hopper 11 will be concentrated and squeezed on one side of the oil residue pressing plate 10, so that the rapeseed oil contained in the oil residue will be squeezed and flow on one side of the oil residue pressing plate 10 again. side and return to the inside of the oil extraction cage 6, thereby reducing the oil content of the oil residue, increasing the oil ext...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap