A method for obtaining a stable lignin: preparing polar organic solvent composition via mild solvolytic modifications

A technology of polar organic solvent and lignin, applied in the field of obtaining stable lignin, polar organic solvent composition, crude lignin oil, can solve the problems of non-economic feasibility, side reaction, solvent consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

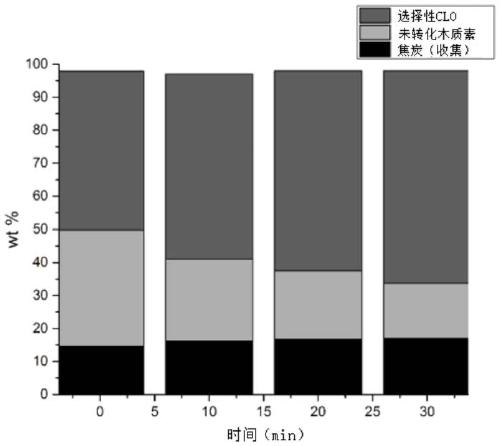

[0079] In the first stage of the process, sulfur-free P1000 soda lignin feedstock is subjected to partial thermocatalytic depolymerization by a mild solvolysis process in the presence of a reaction medium such as ethanol. At an operating temperature below 200°C, a pressure below 50 bar and a residence time of up to 60 minutes, lignin is transformed into a suspension after simple dissolution in ethanol. The solvolysis mixture is first subjected to a solid / liquid separation step such as filtration (2.7 μm) or centrifugation to separate insoluble solids. Depending on the temperature of operation, these solids usually comprise a mixture of char and insoluble lignin, and generally have a rather high heating value as a solid fuel. Lignin is actually fractionated and partially depolymerized in ethanol to selectively produce low yields (≤5 wt %) of C7-C10 alkylphenols and mostly higher molecular weight lignin oligomers. In the second stage of the process, a liquid mixture of lignin a...

Embodiment 2

[0081] choose figure 2 (entries 6 and 7) in two cases to continue to produce CLO-H 1:1 (g / ml). For both cases, a 4 L batch autoclave reactor was used for solvent depolymerization of lignin (first step). The chemical intermediate of this reaction is a mixture of CLO-M, lignin and ethanol, the ratio of which depends on the conversion obtained in the solvolysis step. Then, CLO-M was subjected to vacuum distillation in which ethanol was partially removed. Distillation stops when lignin and ethanol are a stable suspension and lignin does not precipitate. This critical point was found to be close to a lignin to ethanol ratio of 1:1 (g / ml). exist figure 2 In , the mass balances of all streams are given. The recovered ethanol had a purity of 99.6% by weight, while 5-7% by weight of ethanol was lost in the process. The loss was attributed to condensation problems in the reactor piping system. A blank experiment with ethanol alone resulted in similar solvent loss.

Embodiment 3

[0083] The pyrolytic depolymerization process was performed on a sulfur-free P1000 soda lignin feed in the presence of a reaction medium. 13.3 g lignin was added to a 100 ml batch reactor along with 40 ml solvent (50 / 50 ethanol / methanol). use N 2 The reactor was purged and the pressure was set to 10 bar (Pc). The reaction temperature was set at 200° C., the residence time was 30 min, and the reaction pressure was 50 bar. After the reaction, the reactor was cooled to room temperature with an ice bath within 30 minutes. The solvolysis slurry mixture was first subjected to a solid / liquid filtration step (2.7 μm filter paper) using a vacuum air filtration pump. The solid residue usually consists of charcoal. The filtrate (CLO-M) is a liquid mixture of solvent and suspended lignin. The density of CLO-M was measured experimentally and found to be 0.8725 g / ml. The solid residue was found to be 5.9573 grams. To verify the concentration of lignin in CLO-M, a 1 ml sample was subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com