Preparation method of low-cost high-strength concrete pole base

A high-strength cement and low-cost technology, applied in the field of cement products, can solve problems such as high cost, long time required, and difficulty in ensuring strength, and achieve good strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

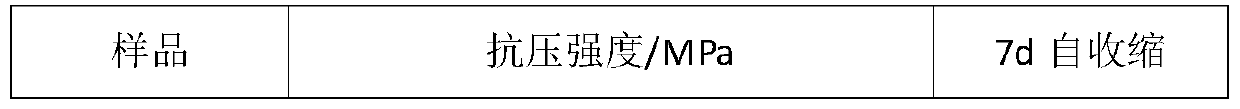

Embodiment 1

[0024] A method for preparing a low-cost high-strength cement rod seat, comprising the following steps:

[0025] A. After mixing the raw materials according to the formula, put them into the rotary mixer and stir evenly. The stirring time is 35 minutes;

[0026] B. Cast the uniformly stirred material into the mold, perform the first constant temperature curing at 65°C, and demould after 10 hours of curing; the base steel plate is installed in the mold; the base steel plate is equipped with There are fixing bolts for fixing the tower base;

[0027] C. Carry out the second constant temperature curing at 32°C, and after 20 hours of curing, the cement rod seat can be obtained.

[0028] In the step A, the material is composed of the following components by weight percentage: 52.5 Portland cement 15%, waste concrete block 55%, recycled refractory brick 15%, expansion agent 1.5%, water reducing agent 2.2% , strengthening additives 0.25% and water balance.

[0029] The particle siz...

Embodiment 2

[0040] A method for preparing a low-cost high-strength cement rod seat, comprising the following steps:

[0041] A. After mixing the raw materials according to the formula, put them into the rotary mixer and stir evenly, and the stirring time is 40min;

[0042] B. Cast the uniformly stirred material into the mold, perform the first constant temperature curing at 60°C, and demould after 12 hours of curing; the base steel plate is installed in the mold; the base steel plate is equipped with There are fixing bolts for fixing the tower base;

[0043] C. Carry out the second constant temperature curing at 30°C, and after 24 hours of curing, the cement rod seat can be obtained.

[0044] In the step A, the material is composed of the following components by weight percentage: 52.5 Portland cement 10%, waste concrete block 60%, recycled refractory brick 8%, expansion agent 3%, water reducing agent 2.5% , strengthening additives 0.2% and water balance.

[0045] The particle size of ...

Embodiment 3

[0056] A method for preparing a low-cost high-strength cement rod seat, comprising the following steps:

[0057] A. Mix the raw materials according to the formula and put them into the rotary mixer to stir evenly. The stirring time is 30min;

[0058] B. Cast the uniformly stirred material into the mold, perform the first constant temperature curing at 70°C, and demould after 8 hours of curing; the base steel plate is installed in the mold; the base steel plate is equipped with There are fixing bolts for fixing the tower base;

[0059] C. Carry out the second constant temperature curing at 35°C, and after 18 hours of curing, the cement rod seat can be obtained.

[0060] In the step A, the material is composed of the following components by weight percentage: 52.5 Portland cement 20%, waste concrete block 50%, recycled refractory brick 20%, expansion agent 1%, water reducing agent 1.5% , strengthening additives 0.3% and water balance.

[0061] The particle size of the waste c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com