Multi-station fixing device used for medium-scale electromechanical device transportation

A technology for electromechanical equipment and fixtures, applied in the directions of transportation and packaging, load fixing, packaging, etc., can solve problems such as shaking of electromechanical equipment, and achieve the effect of avoiding impact and avoiding dislocation of internal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

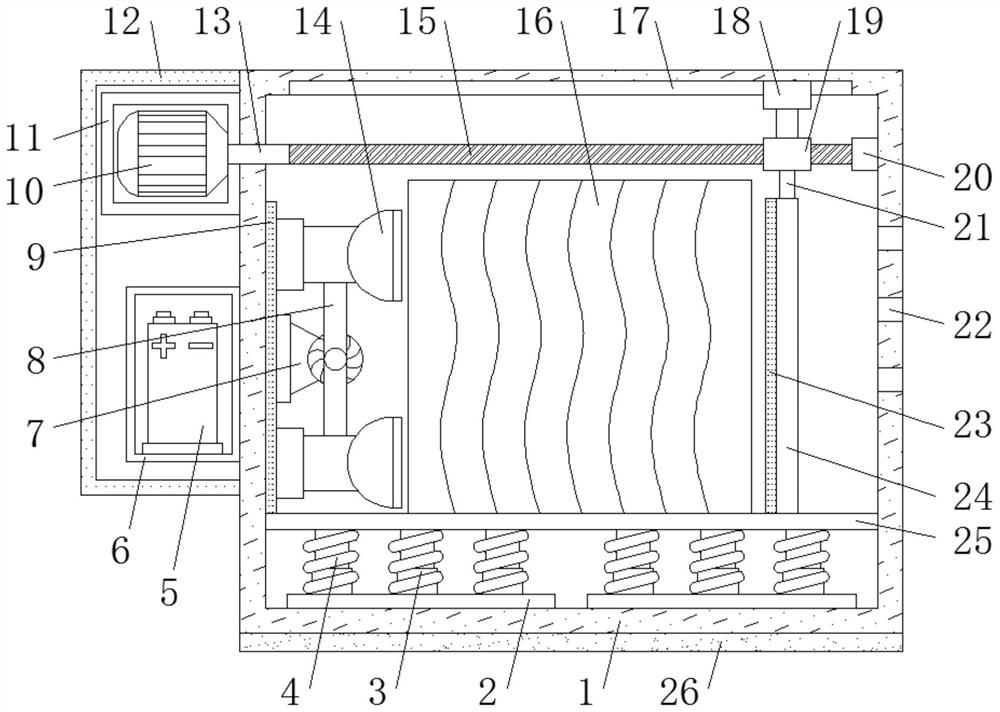

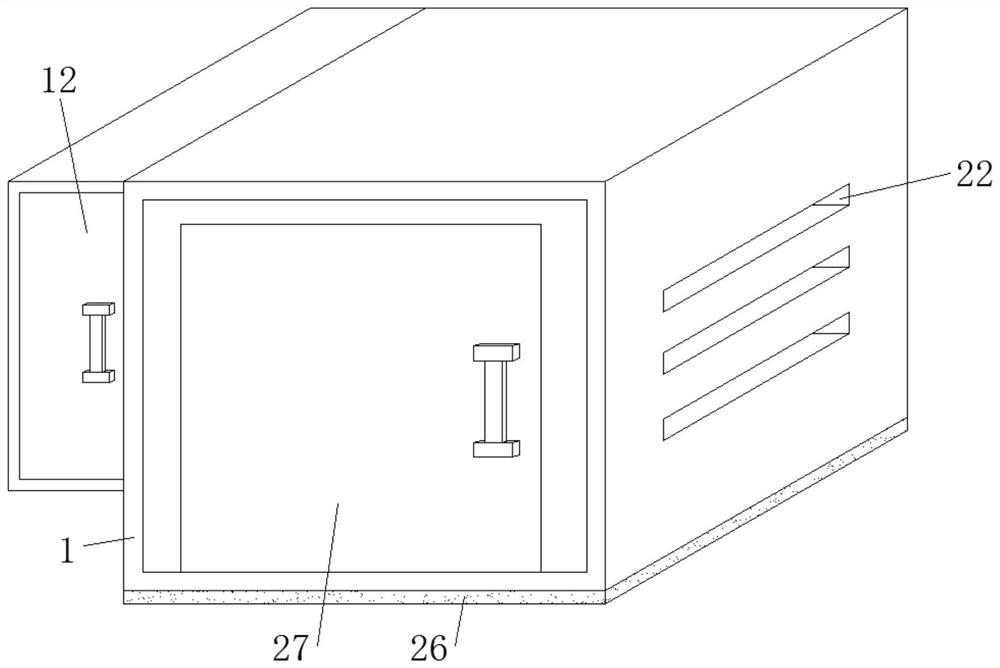

[0026] refer to Figure 1-2 , a medium-sized electromechanical equipment transport multi-position fixing device, comprising a box 1, a plurality of buffer shock absorbing mechanisms are provided on the inner wall of the bottom of the box body 1, and a support plate 25 is fixedly connected to the outer wall of the top of the buffer shock absorbing mechanism, A fixing frame 6 is fixed on the outer wall of one side of the box body 1 by bolts, and a battery 5 is clamped on the inner wall of the bottom of the fixing frame 6, and two motor frames 11 are fixed by bolts on one side of the outer wall of the box body 1 near the top. A motor frame 11 is located above the fixed frame 6, and a motor 10 is fixed by bolts on one side of the motor frame 11. One end of the output shaft of the motor 10 is keyed to a transmission shaft 13, and one end of the transmission shaft 13 is located at the bottom of the casing 1. Inside, one end of the transmission shaft 13 is provided with a limit clamp...

Embodiment 2

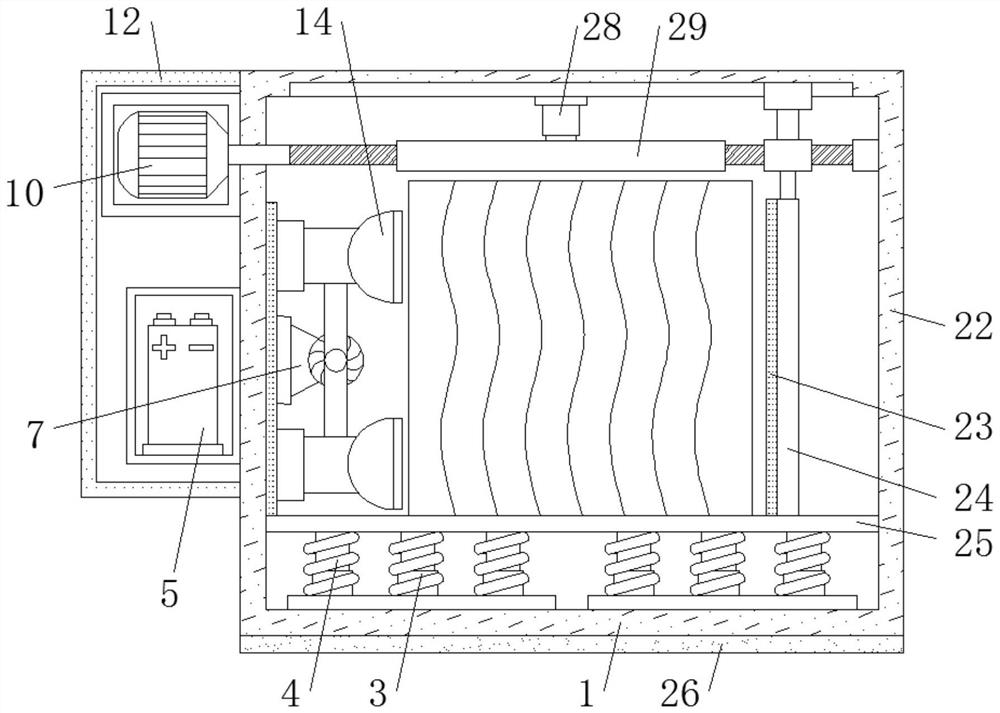

[0031] refer to image 3 , a multi-station fixing device for transportation of medium-sized electromechanical equipment. Compared with Embodiment 1, this embodiment also includes a pressure cylinder 28 and a pressure plate 29. The pressure cylinder 28 is fixed on the middle position of the inner wall of the top of the box body 1 by bolts, and the pressure plate 29 are fixed on one end of the extension rod of the pressure cylinder 28 by bolts.

[0032] When in use, there is also a pressing plate 29 on the inner wall of the top of the box body 1, and the pressing plate 29 is used to press and fix the surface of the electromechanical equipment, so that the transportation process of the electromechanical equipment is more stable.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap