Novel sealing cap special for cosmetic machining feeding device

A technology for feeding devices and cosmetics, applied in packaging, large-scale containers, transportation and packaging, etc., can solve the problems of entering air, difficult operation, and easy loosening of the sealing cover, and achieves improved sealing, good preservation, and increased convenience. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] Example 1

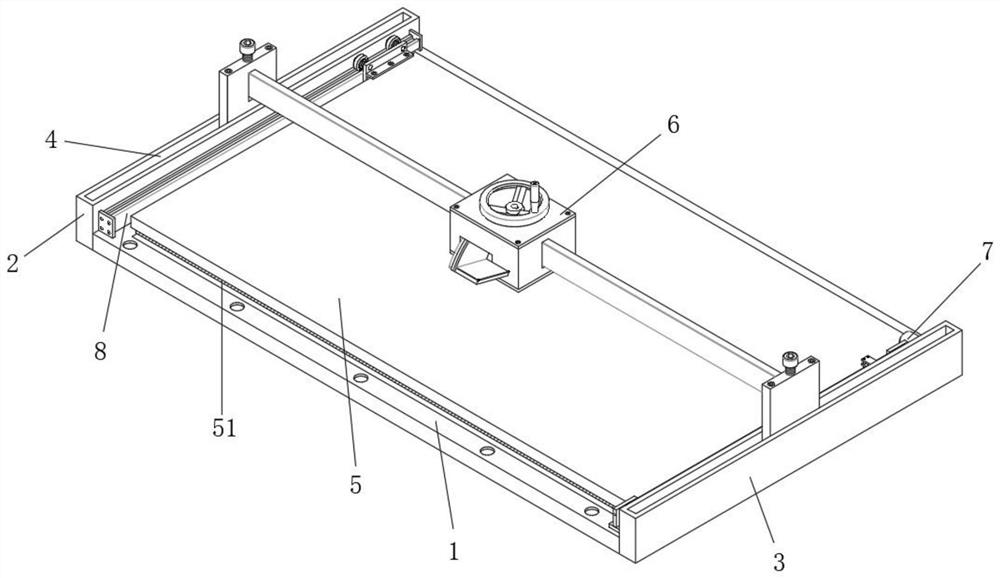

[0032] see figure 1 As shown, the present invention provides a new type of special sealing cover for a cosmetic processing and feeding device through improvement, including a connecting bottom frame 1, a left side plate 2, a right side plate 3, an inner chute 4, a cover plate 5, and a sealing strip 51. , Two-way locking mechanism 6, reciprocating push mechanism 7 and push guide mechanism 8, the left side plate 2 and the right side plate 3 are respectively provided on both sides of the connecting bottom frame 1, and the connecting bottom frame 1 is connected with the silo of the feeding device It is fixed, and the upper end is provided with a cover plate 5 and is closely attached by a sealing strip 51. The set sealing strip 51 increases the sealing between the cover plate 5 and the connection bottom frame 1, and the left side plate 2 and the right side plate 3 are provided with inner slides Slot 4, the cover plate 5 is provided with a two-way locking mechani...

Example Embodiment

[0038] Embodiment 2

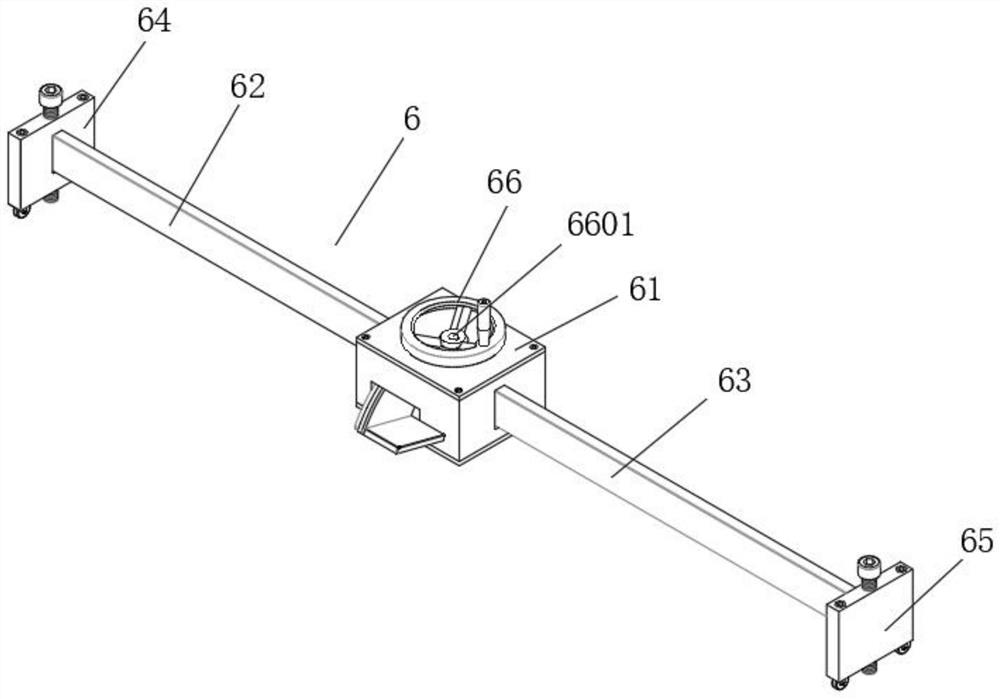

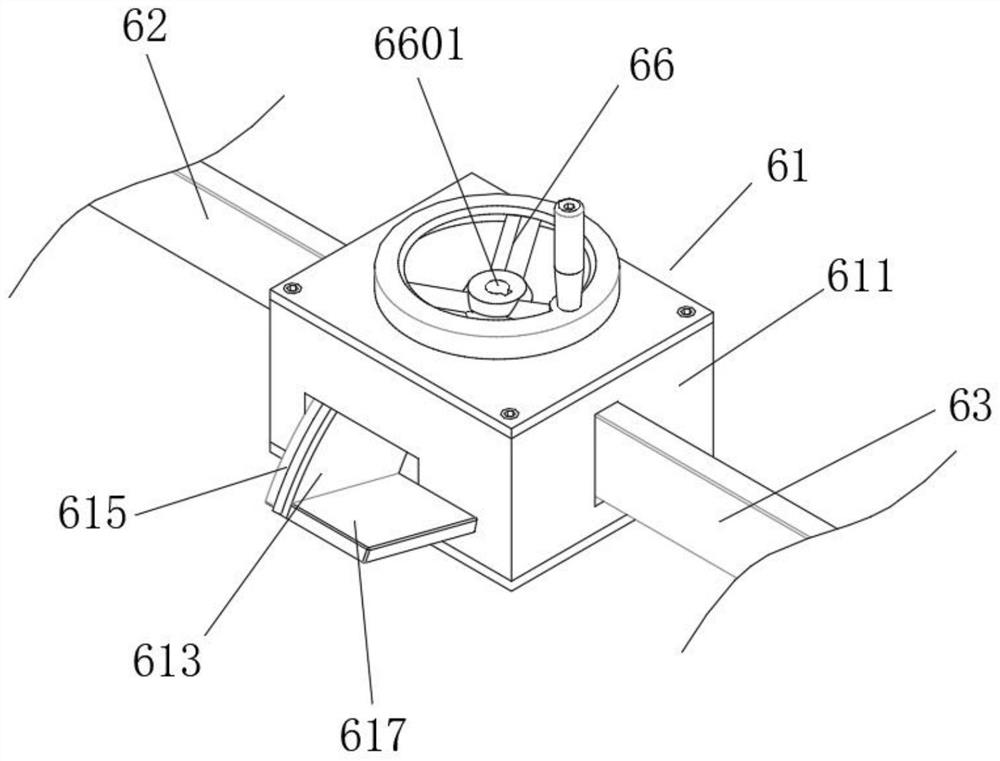

[0039] The present invention provides a new type of special sealing cover for a cosmetic processing and feeding device through improvement. The first connecting rod 62 and the second connecting rod 63 respectively penetrate through the outer frame 611 of the locking structure 61 from both sides to connect to the left sliding position The seat 616 and the right sliding positioning seat 619, and the middle of the two ends of the outer frame body 611 is provided with a through groove to fit the first connecting rod 62 and the second connecting rod 63, so that the outer frame 611 passes through the first connecting rod. 62 and the second connecting rod 63 are positioned so that there will be no offset, the first lower pressing plate 617 and the second lower pressing plate 6110 are both arranged outside the outer frame 611, and the front and rear ends of the outer frame 611 are provided with left bevel teeth A through slot through which the rod 613 , the right...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap