Method for recycling nylon/polyolefin composite membrane by utilizing ionic liquid

A technology for recycling nylon and ionic liquid, which is applied in the field of recycling nylon/polyolefin composite membrane by using ionic liquid, can solve problems such as nylon recycling that is not mentioned, and achieve the effects of reducing energy consumption, simple separation process, and reducing recycling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0040] Example 1

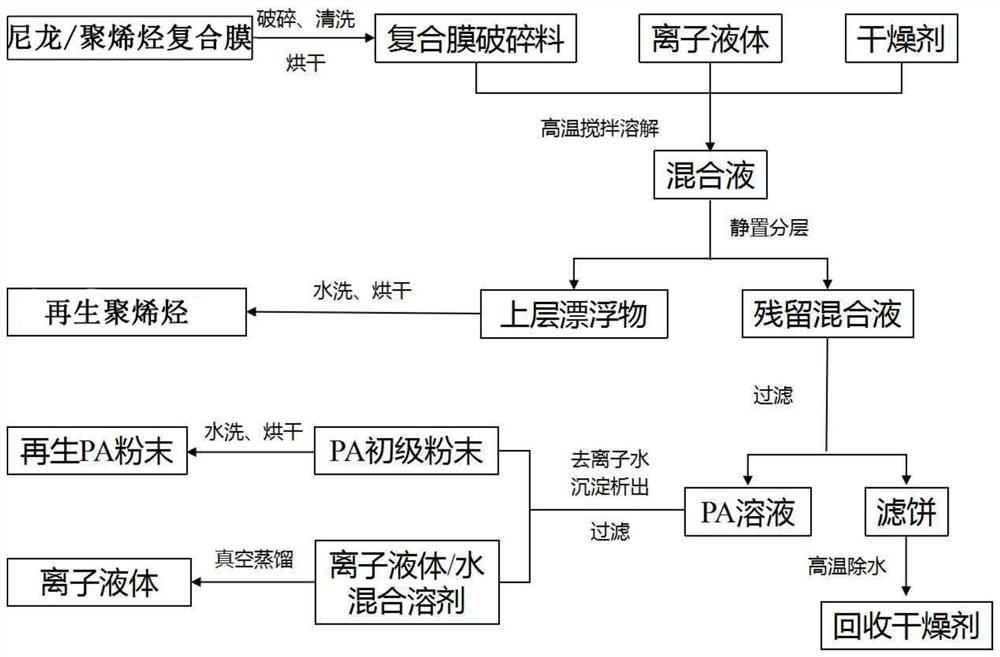

[0041] The recovery method of this embodiment:

[0042] Take 10g of the crushed material of PA / PE composite membrane after crushing, cleaning and drying, and 1g of anhydrous CaCl 2 Add to 100g of ionic liquid 1-ethyl-3-methylimidazolium bromide, and heat to 180°C under the protection of nitrogen atmosphere and stir to dissolve for 1.5h. Let it stand for 2 hours. During the standing process, the temperature is lowered to 80°C and stored at a constant temperature. The floating PE on the upper layer is taken out, and the residual ionic liquid on the surface is removed by washing with deionized water three times to obtain a clean PE. Filter the solution to filter out CaCl 2 , Put it in an oven at 220°C for 1 hour to obtain reusable anhydrous CaCl 2 . The filtered solution is added to deionized water, PA precipitates out, filtered, and the filtered liquid is processed by vacuum distillation to separate the ionic liquid and water to obtain a reusable ionic liquid. Th...

Example Embodiment

[0043] Example 2

[0044] The difference between the recovery method of Example 2 and Example 1 is that: Example 2 is not stored at a constant temperature during the static process, and it is left to stand naturally for 2 hours. Others are the same as Example 1.

[0045] Since the melting point of 1-ethyl-3-methylimidazolium bromide ionic liquid is about 71°C, during the standing process, the ionic liquid is solidified due to no constant temperature storage, and PE, PA and ionic liquid cannot be separated.

Example Embodiment

[0046] Example 3

[0047] The recovery method of this embodiment:

[0048] Take 10g of the crushed material of PA / PE composite membrane after crushing, cleaning and drying, and 1g of anhydrous CaCl 2 It was added to 100g of ionic liquid 1-ethyl-3-methylimidazole trifluoromethanesulfonate, and heated to 170°C under the protection of a nitrogen atmosphere, stirred and dissolved for 2h. After standing for 3 hours, the upper layer of floating PE was taken out, and the residual ionic liquid on the surface was removed by washing with deionized water three times to obtain clean PE. Filter the solution to filter out CaCl 2 , Put it in an oven at 230°C for 1.5 hours to obtain reusable anhydrous CaCl 2 . The filtered solution is added to deionized water, PA precipitates out, filtered, and the filtered liquid is processed by vacuum distillation to separate the ionic liquid and water to obtain a reusable ionic liquid. Then, the filtered material was washed with deionized water three times to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap