Preparation method of cadmium sulfide layer of copper-indium-gallium-selenium solar cell, solar cell and method for growing cadmium sulfide layer on copper-indium-gallium-selenium layer

A technology of solar cells and copper indium gallium selenide, which is applied in the field of solar cells, can solve problems such as pinholes and battery short circuits, and achieve the effects of avoiding pinholes and improving quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

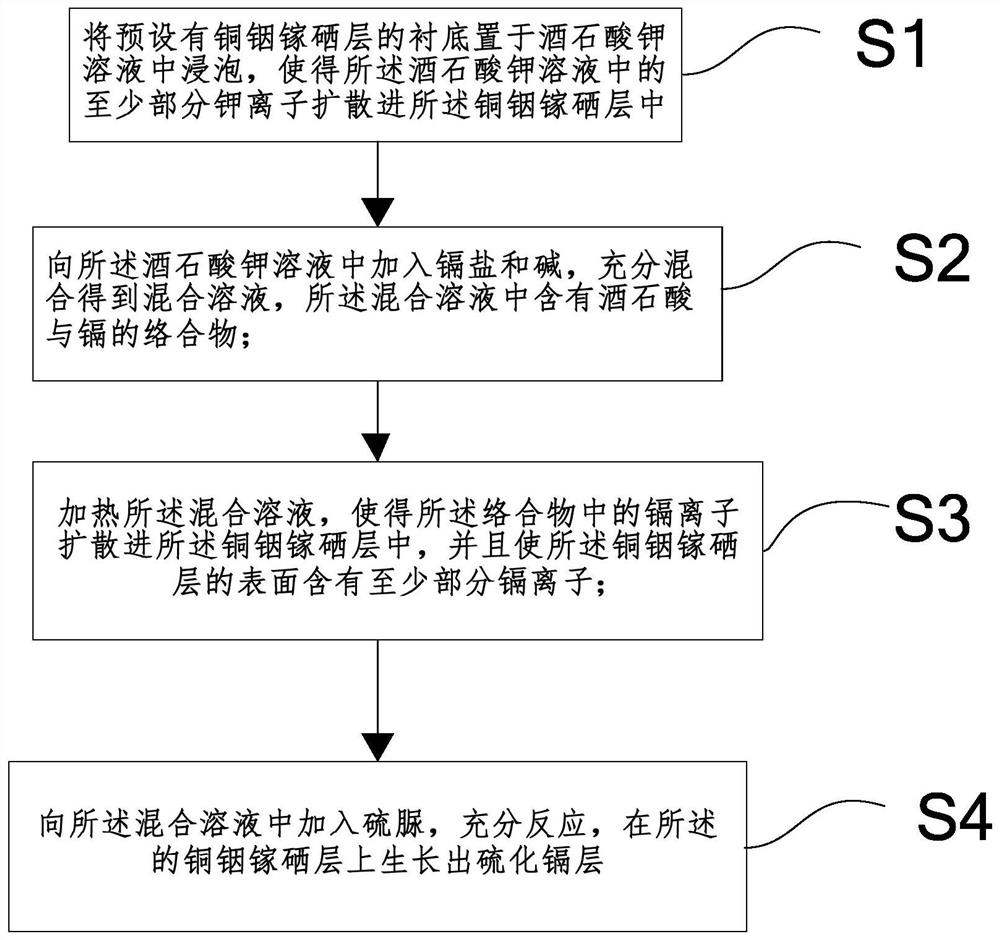

[0054] The invention provides a method for preparing a cadmium sulfide layer of a copper indium gallium selenide solar cell, the preparation method of the cadmium sulfide layer comprising:

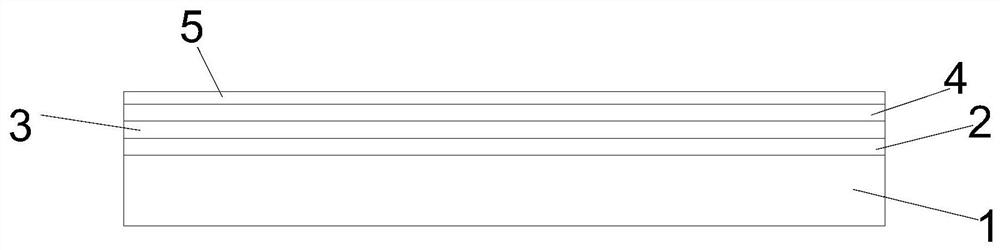

[0055] S1: Soak the substrate 1 preset with the CIGS layer 2 in a potassium tartrate solution, so that at least part of the potassium ions in the potassium tartrate solution diffuse into the CIGS layer 2;

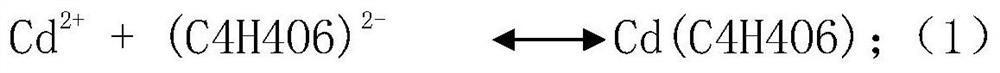

[0056] S2: add cadmium salt and alkali to described potassium tartrate solution, fully mix to obtain mixed solution, contain the complex of tartaric acid and cadmium in described mixed solution;

[0057] S3: heating the mixed solution, so that the cadmium ions in the complex diffuse into the CIGS layer 2, and make the surface of the CIGS layer 2 contain at least part of the cadmium ions; and

[0058] S4: Add thiourea to the mixed solution, fully react, and grow a cadmium sulfide layer 3 on the copper indium gallium selenide layer 2.

[0059] In step S1, potassium tartrate is used to soak...

Embodiment 2

[0088] The invention provides a method for preparing a cadmium sulfide layer of a copper indium gallium selenide solar cell, the preparation method of the cadmium sulfide layer comprising:

[0089] S1: Soak the substrate 1 preset with the CIGS layer 2 in a potassium tartrate solution, so that at least part of the potassium ions in the potassium tartrate solution diffuse into the CIGS layer 2;

[0090] S2: add cadmium salt and alkali to described potassium tartrate solution, fully mix to obtain mixed solution, contain the complex of tartaric acid and cadmium in described mixed solution;

[0091] S3: heating the mixed solution, so that the cadmium ions in the complex diffuse into the CIGS layer 2, and make the surface of the CIGS layer 2 contain at least part of the cadmium ions; and

[0092] S4: Add thiourea to the mixed solution, fully react, and grow a cadmium sulfide layer 3 on the copper indium gallium selenide layer 2.

[0093] In step S1, potassium tartrate is used to so...

Embodiment 3

[0122] The invention provides a method for preparing a cadmium sulfide layer of a copper indium gallium selenide solar cell, the preparation method of the cadmium sulfide layer comprising:

[0123] S1: Soak the substrate 1 preset with the CIGS layer 2 in a potassium tartrate solution, so that at least part of the potassium ions in the potassium tartrate solution diffuse into the CIGS layer 2;

[0124] S2: add cadmium salt and alkali to described potassium tartrate solution, fully mix to obtain mixed solution, contain the complex of tartaric acid and cadmium in described mixed solution;

[0125] S3: heating the mixed solution, so that the cadmium ions in the complex diffuse into the CIGS layer 2, and make the surface of the CIGS layer 2 contain at least part of the cadmium ions; and

[0126] S4: Add thiourea to the mixed solution, fully react, and grow a cadmium sulfide layer 3 on the copper indium gallium selenide layer 2.

[0127] In step S1, potassium tartrate is used to so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com