AGV carrying goods shelf positioning system and method

A positioning system and shelf technology, which is applied in the field of AGV warehouses and warehousing and logistics equipment, can solve problems such as difficult maintenance, two-dimensional code pasting errors, and inconvenient maintenance, and achieve the effect of cost reduction and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

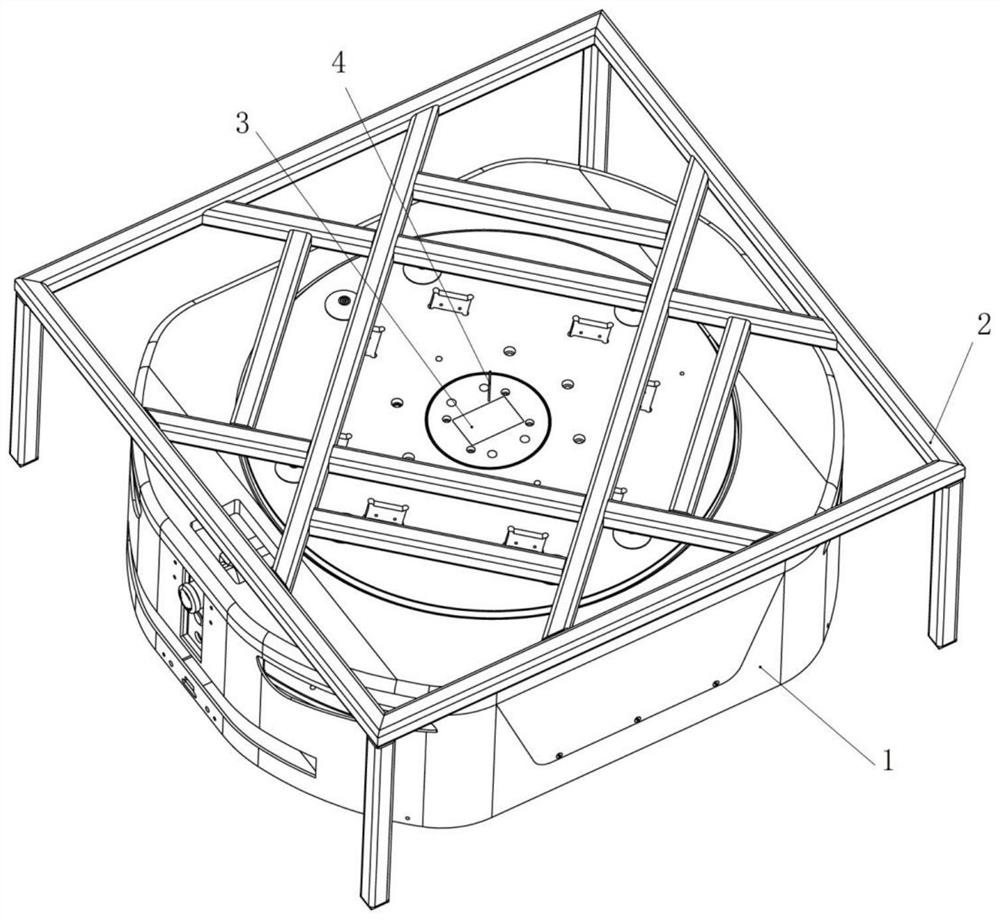

[0023] see figure 1 , the square infrared sensing frame 3 is set on the lifting plate at the center of the AGV transport trolley 2, and the center of the infrared sensing frame is the center of the trolley.

[0024] The probe 4 is placed at the center position under the shelf 2 .

[0025] After the probe is sensed by the infrared sensing frame, the current corresponding X and Y coordinate values in the frame can be output to determine the offset of the probe relative to the infrared sensing frame, and then determine the offset between the AGV trolley and the shelf.

[0026] The relative position data of the center of the infrared sensing frame and the center of the lifting plate is known, and the relative position data of the sharp part on the top of the probe used for measuring and sensing and the center of the shelf is known. Scaling and measuring offset data can be done bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diagonal size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com