Stacking machine for stacking goods

A stacking machine and cargo technology, which is applied to the stacking of objects, conveyors, conveyor objects, etc., can solve the problems of uneven stacking, low precision, and easy stacking, and achieve low and high stacking accuracy. Accurate stacking and the effect of improving handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

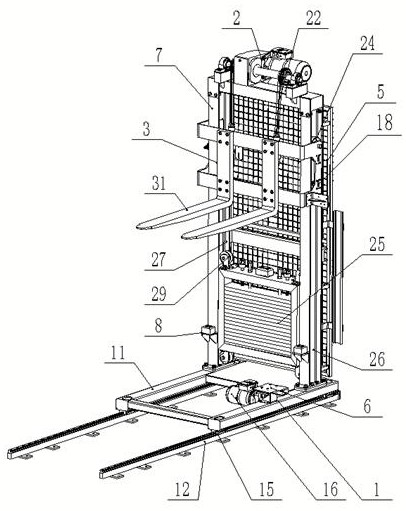

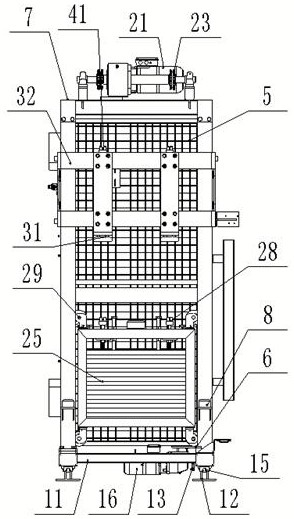

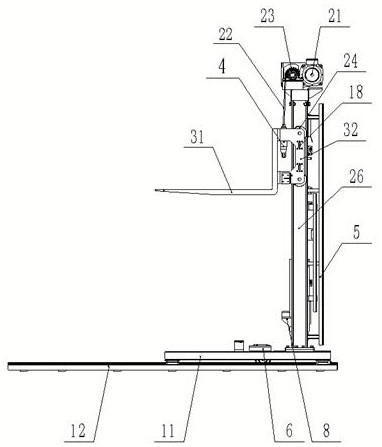

[0034] The stacking machine for stacking goods includes a main frame 7, a lifting mechanism 2, a fork mechanism 3, and a stacking guide rail 12. It also includes a running device 1 and a detection device 4, and a lifting mechanism is provided on the main frame 2. The inner side of the main frame is provided with sliding rails. The two sides of the fork mechanism are slidably connected to the sliding rails of the main frame. The fork mechanism is connected to the lifting motor 21 through the lifting mechanism. The counterweight device is connected to the bottom of the fork. A fork is arranged on the side, and a detection device is also arranged between the fork mechanism and the lifting mechanism;

[0035] An operating device is arranged at the bottom of the main frame, and the operating device is connected with an operating decelerating motor, and is slidably connected with the stacking guide rail. The stacking guide rail may be a linear guide rail.

[0036] The operating device in...

Embodiment 2

[0053] In the structure of embodiment 1, the linkage device can also be configured as a matched synchronous wheel and synchronous belt structure, the running gear motor is connected with a synchronous wheel 191, and the synchronous wheel is connected with a running shaft 192 through the running synchronous belt 193, and two running shafts Both ends are provided with a gear 13 and a rack 14 meshingly connected with the gear. The rack has a non-fixed length, and the length is determined according to the moving distance. The rack is parallel to the stacking rail 12. The setting of the running axis can enhance the stability of the running mechanism.

[0054] The lifting device can also be configured as a matching lifting timing belt 201 and a timing pulley 202. The timing pulley is located on the top of the main frame 7 and is connected with a lifting motor 21. The timing pulley 202 is meshed and connected with a timing belt. The two ends of the belt 201 and the synchronous belt are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com