Agalloch eaglewood water and oil mixture and preparation method thereof

A technology of mixture and agarwood, which is applied in the direction of botany equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of reducing the use efficiency, unpleasant smell, oil-water separation, etc., and achieve the repair of scars, Helps skin recovery and promotes skin repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

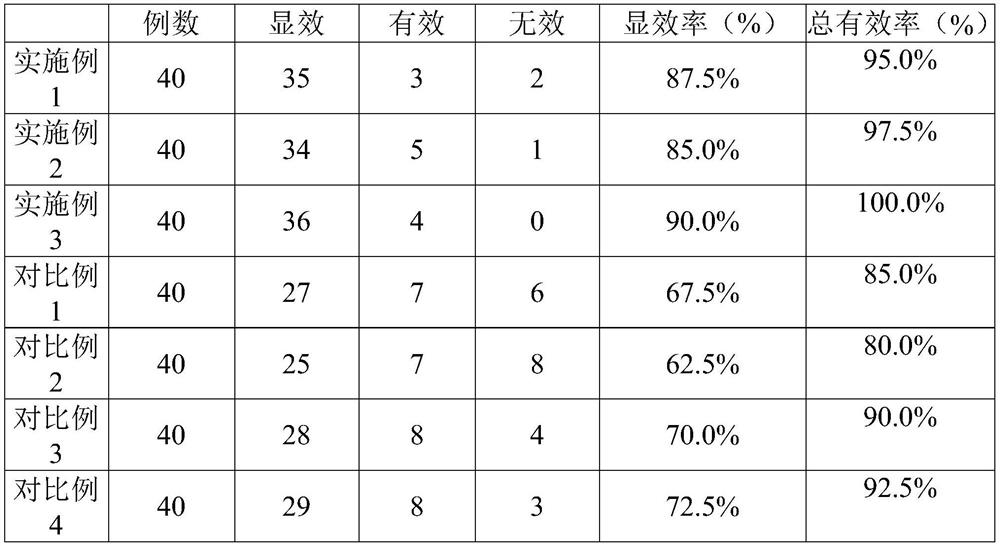

Examples

Example Embodiment

[0021] Example 1

[0022] A kind of perfume oil mixture, its preparation method comprises the following steps:

[0023] (1) Take agarwood shell material and water according to the material-to-liquid ratio g / ml 1:8 and mix, heat to boiling for 10 minutes, and collect condensed water to prepare agarwood distilled water;

[0024] (2) Take agarwood board stock and agarwood peel oil at a mass ratio of 1:3, wash, dry, and grind into a 160-mesh fine powder to prepare agarwood powder. Add boiled agarwood according to the material-to-liquid ratio of g / ml 1:0.8 The shell material is mixed with water, and 1w / w% Lactobacillus powder is added to ferment for 28 hours to obtain agarwood fermented product;

[0025] (3) The fermented agarwood is extracted with supercritical carbon dioxide. The materials are first extracted at 40°C and 0.4MPa for 1.2 hours to obtain agarwood oil A; the materials are then extracted at 20°C and 4MPa for 0.6 hours to obtain agarwood oil B; The final materials were extrac...

Example Embodiment

[0027] Example 2

[0028] A kind of perfume oil mixture, its preparation method comprises the following steps:

[0029] (1) Take agarwood shell material and water according to the material-to-liquid ratio g / ml 1:12 and mix, heat to boiling for 20 minutes, and collect the condensed water to prepare agarwood distilled water;

[0030] (2) Take agarwood board stock and agarwood peel oil at a mass ratio of 1:5, wash, dry, and grind into 200 mesh fine powder to prepare agarwood powder, add boiled agarwood according to the material-to-liquid ratio of g / ml 1:1.2 The shell material is mixed with water, and 3w / w% lactobacillus powder is added to ferment for 20 hours to obtain agarwood fermented product;

[0031] (3) The fermented agarwood is extracted with supercritical carbon dioxide. The materials are first extracted at 60°C and 0.6MPa for 0.8h to obtain agarwood oil A; the materials are then extracted at 30°C and 6MPa for 0.4h to obtain agarwood oil B; The final materials were extracted at ...

Example Embodiment

[0033] Example 3

[0034] A kind of perfume oil mixture, its preparation method comprises the following steps:

[0035] (1) Take agarwood shell material and water according to the material-to-liquid ratio g / ml 1:10 and mix, heat to boiling for 15 minutes, and collect the condensed water to prepare agarwood distilled water;

[0036] (2) Take agarwood board stock and agarwood peel oil at a mass ratio of 1:4, wash, dry, and grind into a fine powder of 200 mesh to prepare agarwood powder, add boiled agarwood according to the material-to-liquid ratio of g / ml 1:1 The shell material is mixed with water, and 2w / w% Lactobacillus powder is added for 24h to prepare agarwood fermented product;

[0037] (3) The fermented agarwood is extracted with supercritical carbon dioxide. The materials are first extracted at 50°C and 0.5MPa for 1h to obtain agarwood oil A; the materials are then extracted at 25°C and 5MPa for 0.5h to obtain agarwood oil B ; Finally, the materials were extracted at 20°C and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap