Silicon-free mud cake pretreatment device for iron oxide production

A pretreatment device, the technology of desiliconization mud cake, applied in the directions of iron oxide, sludge treatment, iron oxide/iron hydroxide, etc., to achieve the effect of ensuring pretreatment and ensuring fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

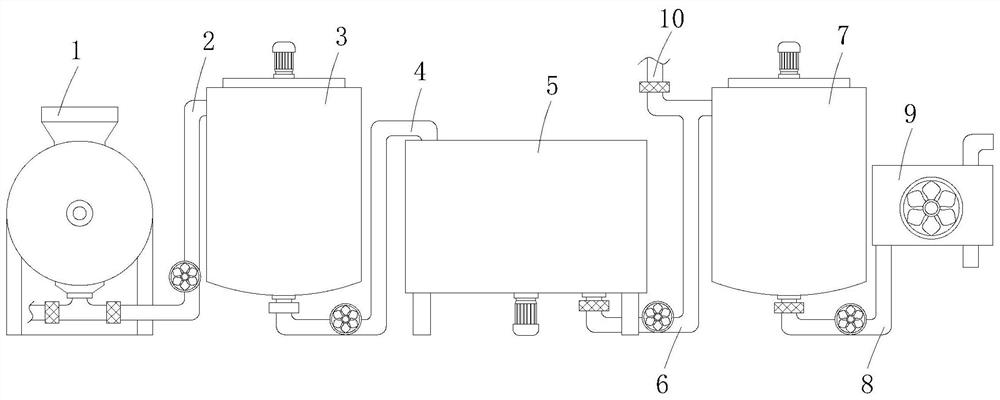

[0040] A desiliconization mud cake pretreatment device for iron oxide production, including a mud cake crusher 1, a beating mechanism I3, a rinsing and filtering mechanism 5, a beating mechanism II7, a centrifuge 9, and a mud cake crusher 1 arranged in sequence along the treatment process The output end of the beating mechanism I3 is connected to the beating mechanism I3 through the mud pipe I2, the output end of the beating mechanism I3 is connected to the rinsing and filtering mechanism 5 through the mud pipe II4, and the output end of the rinsing and filtering mechanism 5 is connected to the beating mechanism II7 through the mud pipe III6. The output end of the beating mechanism II7 is connected with the centrifuge 9 through the mud pipe IV8;

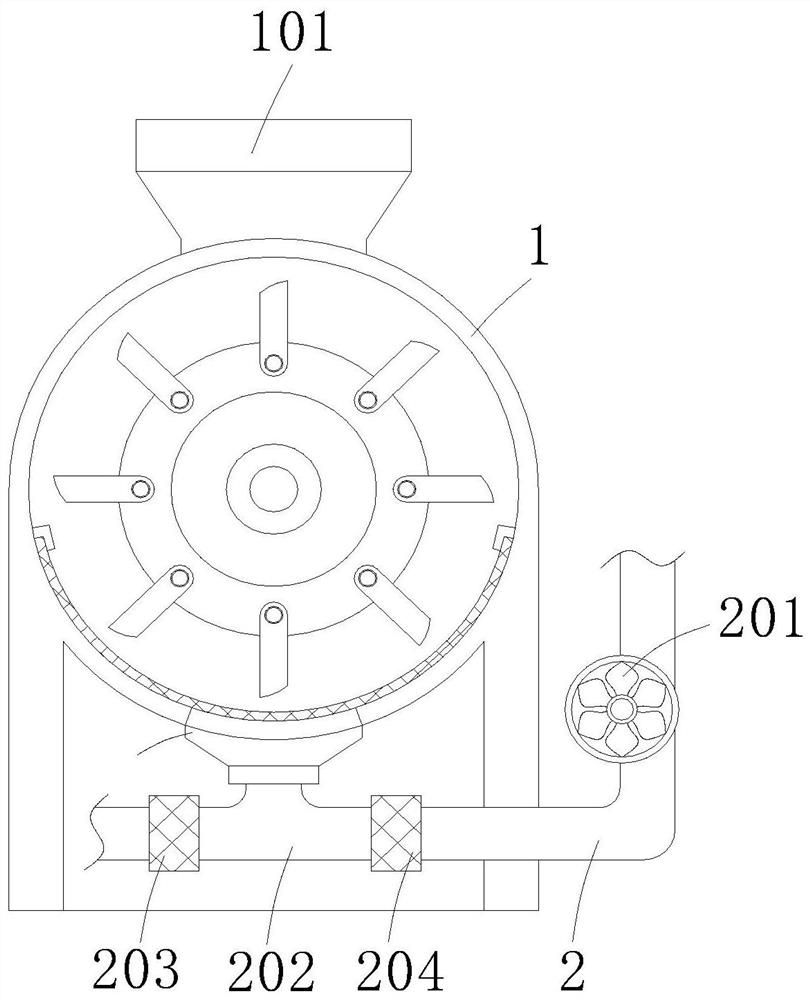

[0041] In this example, if figure 2 As shown, the output end of the mud pipe I2 is connected with a water delivery pipe I202, and the other end of the water delivery pipe I202 is connected with an external water source, and a water ...

Embodiment 2

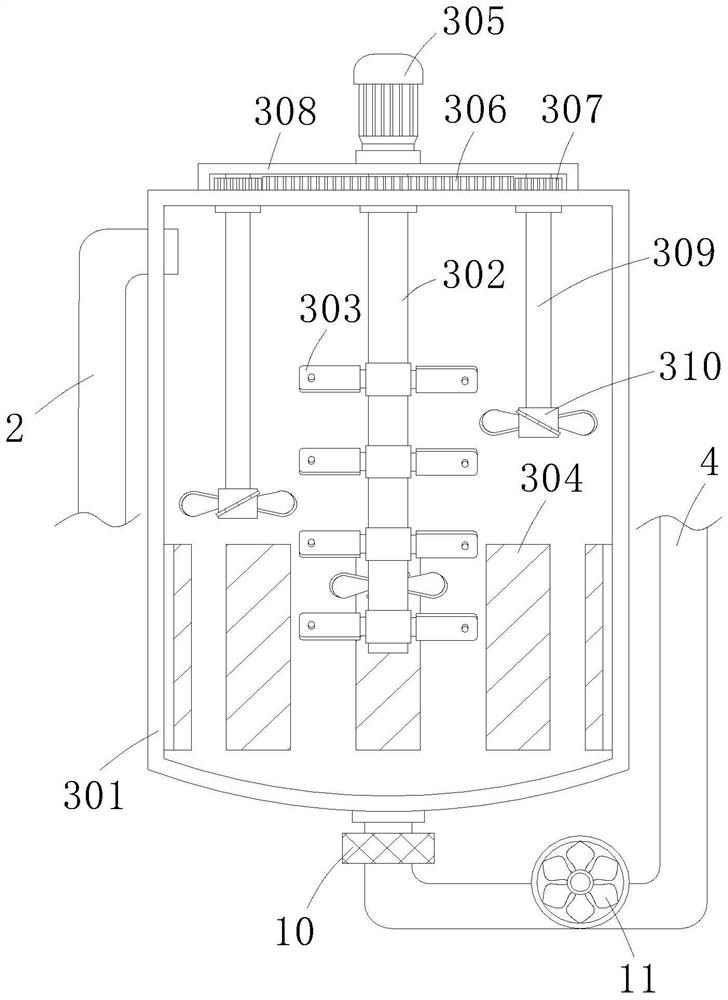

[0054] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, the lower part of the inner cavity of the tank body 301 of the beating mechanism I3 and the beating mechanism II7 is equipped with a plurality of electric heating plates 304 distributed in a circular array along the inner wall. The specifications of the beating mechanism I3 and the beating mechanism II7 are consistent. It can be understood that, The beating mechanism Ⅱ7 is also equipped with a circular array of electric heating plates, which are heated when the mud cake is beating. The increase in temperature can effectively improve the beating efficiency, ensure the mixing of mud and water, and improve the fineness of the mud.

[0055] Refer to Example 1 for other undescribed structures.

[0056] The above-mentioned desiliconization mud cake pretreatment device for iron oxide production provided in this example breaks the mud cake first through the mud cake crusher 1, so that the dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com