Mortise and tenon self-locking assembly type wall column joint connecting structure

A node connection and assembly technology, applied in the direction of walls, building components, building structures, etc., to achieve the effect of safe and reliable connection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

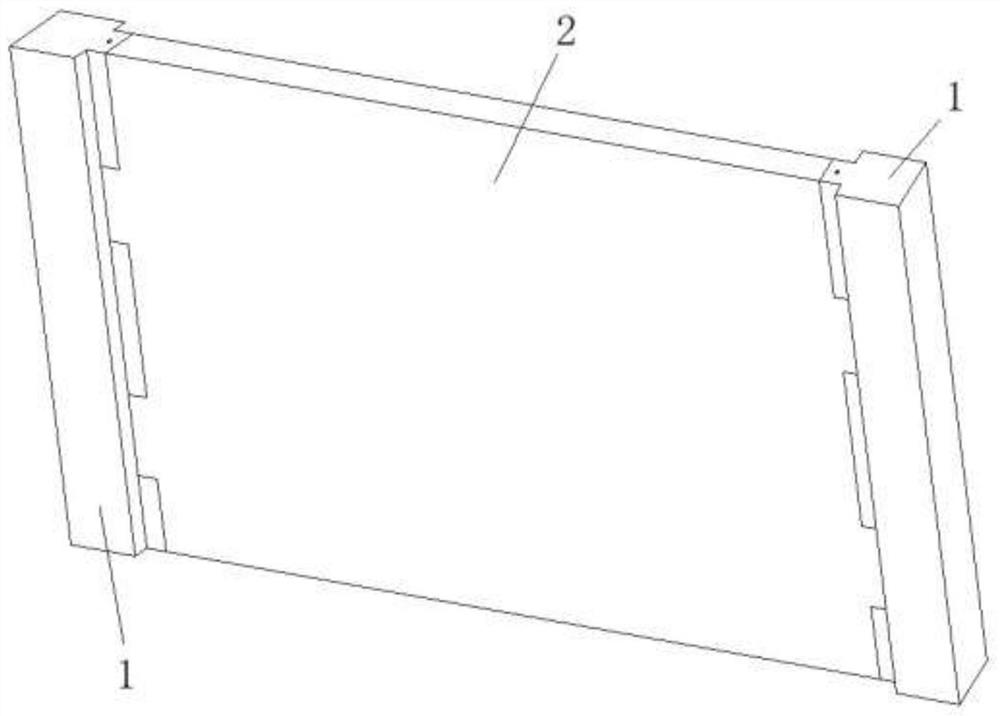

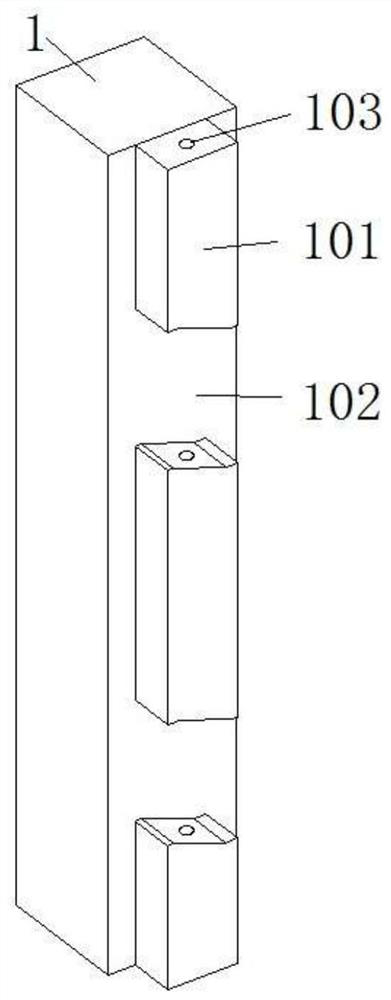

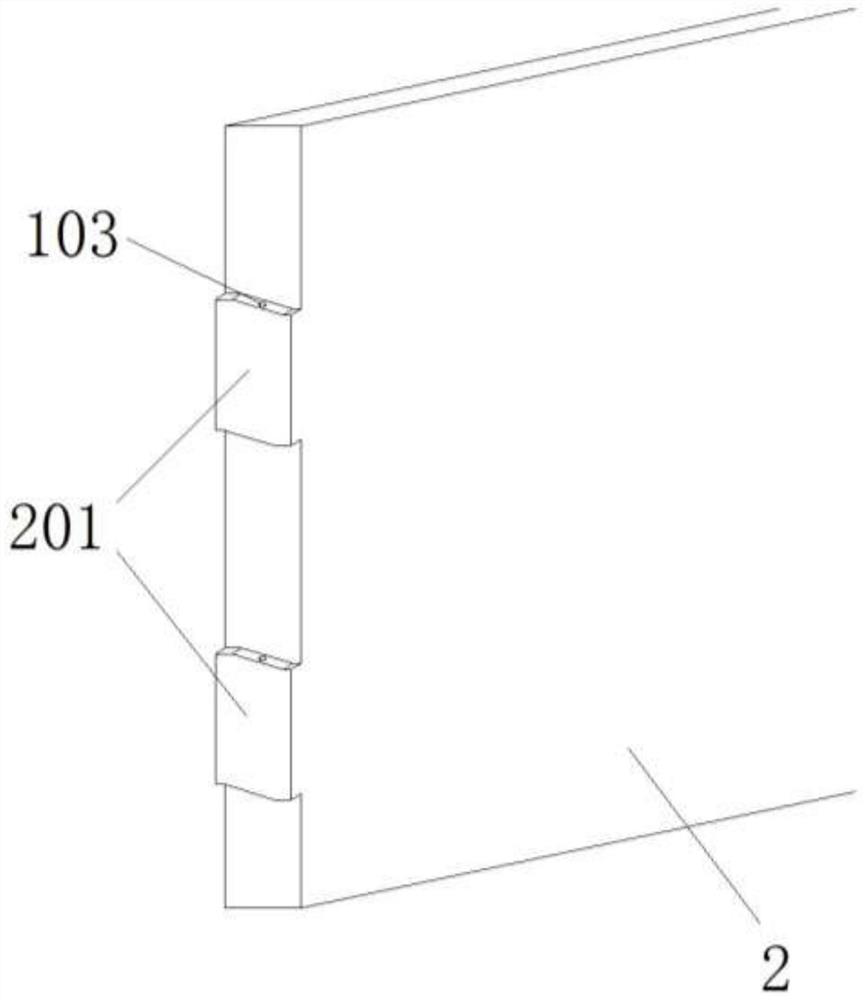

[0025] Such as Figure 1-Figure 3 As shown, the mortise and tenon self-locking assembled wall column structure of the present invention includes a structural column 1 and a wall panel 2. Three connecting blocks 11 are arranged on the structural column to form two sockets 12. The thickness of the connecting block is the same as that of the wall panel. Same, each connection block is provided with planting reinforcement holes 13; the end of the wallboard is provided with two tenons 21 matching the mortise, the thickness of the tenons is the same as that of the wallboard, and each tenon is also provided with planting holes. Reinforcement hole 13; After the tenon is inserted into the mortise, the wallboard, tenon and connecting block form a whole, and all the rebar holes are on the same straight line, and the diameter of the rebar hole is at least 20mm larger than the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com