Three-shaft multi-stage Roots pump

A Roots pump and pump casing technology, applied in the field of three-axis multi-stage Roots pumps, can solve problems such as large cumulative errors, achieve the effects of reducing the use of parts, ensuring pumping efficiency, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

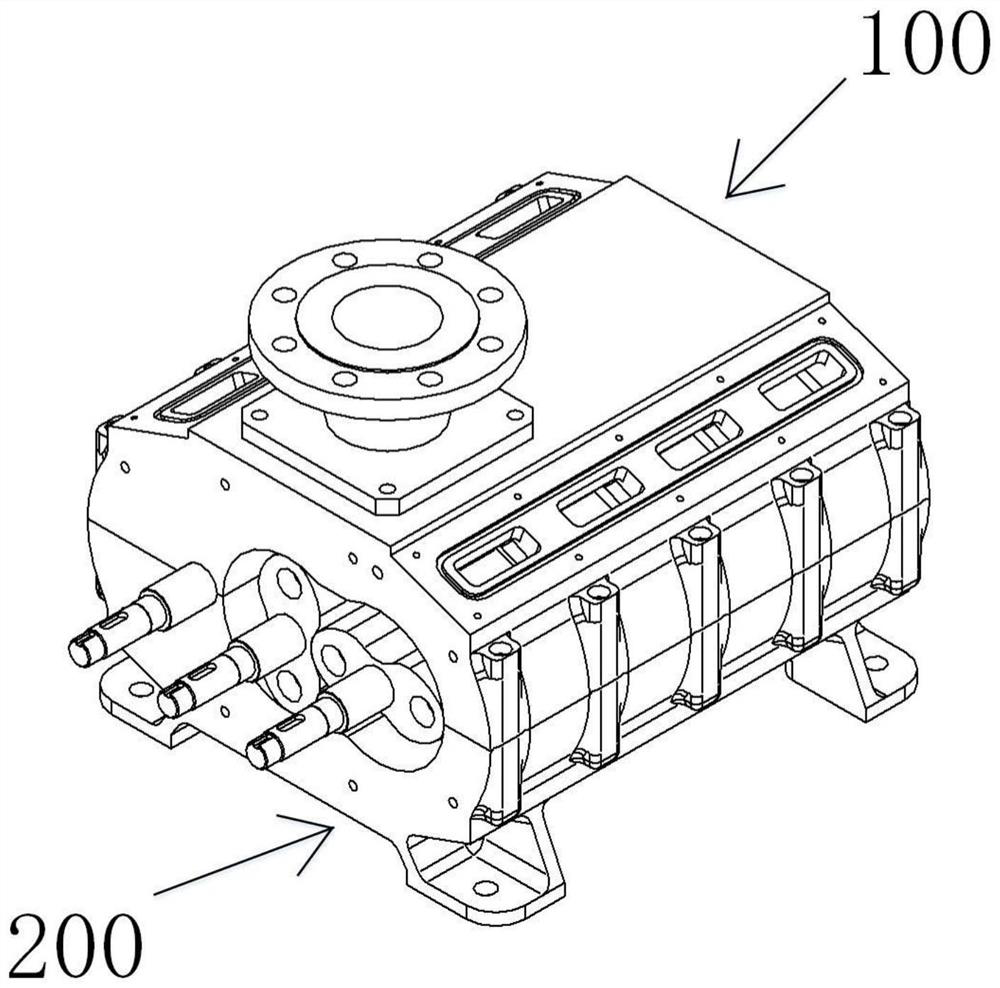

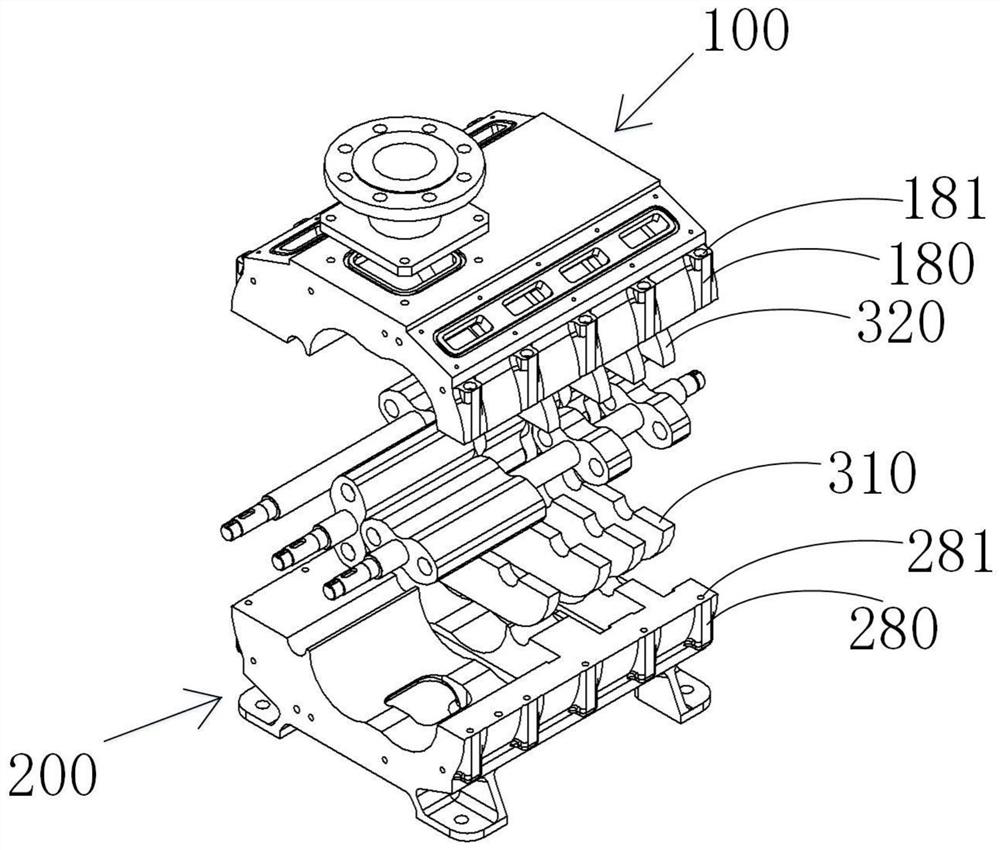

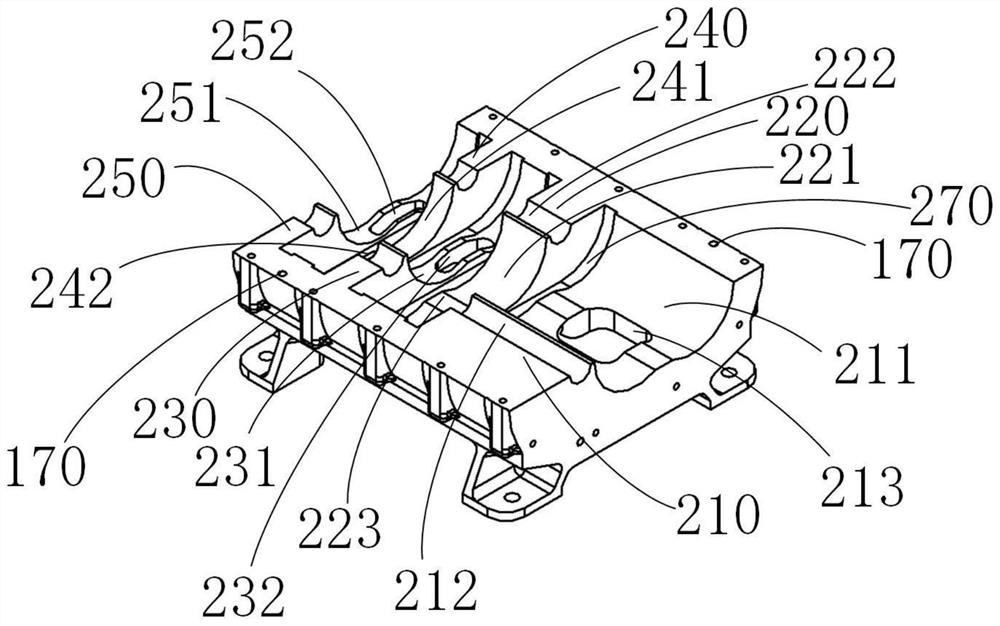

[0063] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5, as a specific embodiment of the present invention, the three-shaft multi-stage Roots pump includes a pump casing, a multi-stage Roots rotor disposed in the pump casing and three rotating shafts, the three rotating shafts are respectively the first rotating shaft 460 and the second rotating shaft 470 and the third rotating shaft 480 , the pump casing includes an upper pump casing 100 and a lower pump casing 200 . Wherein, the lower end surface of the upper pump casing 100 is respectively provided with a first positioning hole 170 near the two axial ends, and correspondingly, the upper end surface of the lower pump casing 200 is also respectively provided with a first positioning hole 170 near the axial ends. A positioning pin can be inserted into the first positioning hole 170 . The first positioning hole 170 can improve the accuracy of assembling the upper and lower pump casings. When the upper pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com