Special salt spoon with vibration salt spreading according to number of people

A technology of people and salt spoons, applied in the field of household tableware and healthy eating, to achieve the effect of quantifying the amount of scooping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

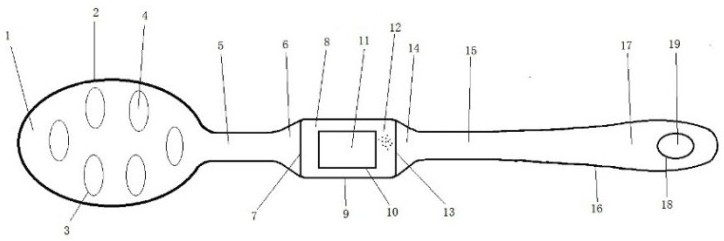

[0026] As shown in the figure, a special salt spoon for quantifying the number of people to shake salt is made of all stainless steel; including: spoon head tip 1; spoon head 2; small pit 3 on the spoon head; small pit ellipsoid Hemisphere bottom 4; spoon head short handle 5; horn-shaped beautification short handle 6; piston tube bottom 7; the hollow part of the piston tube 8; piston tube (cylindrical side wall) 9; solid piston 10; solid piston with a certain weight Core piston filler 11; lubricating powder (fine particles for lubrication) 12; the cylindrical top of the piston tube 13; the horn-shaped beautification short handle 14; the long handle of the spoon 15; the edge of the long handle of the spoon 16; the tail of the long handle of the spoon 17 ; Long handle tail hanging hole 18; Long handle tail hanging hole hole part 19.

[0027] When using the salt spoon, submerge the head of the spoon in the salt shaker, take it out and tilt and shake it, shake the excess salt except ...

Embodiment 2

[0037] As shown in the figure, a special salt spoon that quantifies and shakes salt according to the number of people is made of hard and transparent food-grade plastic, red hard and wear-resistant plastic and metal iron; including: spoon head tip 1; spoon head 2; Small pit 3 on the spoon head; small pit ellipsoid hemisphere bottom 4; spoon head short handle 5; horn-shaped beautification short handle 6; piston tube bottom 7; piston tube hollow part 8; piston tube (cylindrical side Wall) 9; solid piston 10; solid piston filler 11 with a certain weight; lubricating powder 12; cylindrical top of the piston tube 13; horn-shaped beautifying short handle 14; spoon long handle 15; spoon long handle edge 16; The tail 17 of the long handle of the spoon; the tail hanging hole 18 of the long handle; the hanging hole part 19 of the long handle tail.

[0038] When using the salt spoon, the head of the spoon is immersed in the salt shaker, and after taking it out, it is tilted and shaken, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com