Superimposed concrete reinforcement and reinforcement floor and construction technology

A concrete reinforcement and concrete technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of cumbersome disassembly steps, increase construction steps, time-consuming and labor-intensive problems, achieve good reinforcement effect and simplify construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

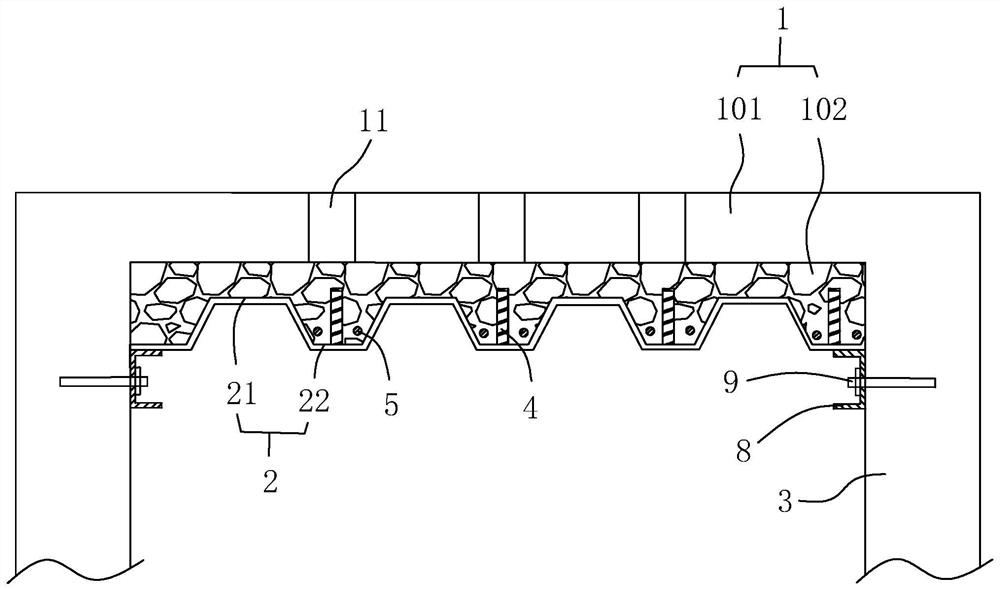

[0036] A composite concrete reinforced floor slab, such as figure 1 As shown, it includes a concrete layer 1 and a steel plate 2 fixed below the concrete layer 1 , the surrounding side of the steel plate 2 is connected to the structural column 3 of the building, and the concrete layer 1 is poured on one side surface of the steel plate 2 . It should be noted that the shape of the steel plate 2 is made according to construction requirements. In this embodiment, the steel plate 2 is a square plate.

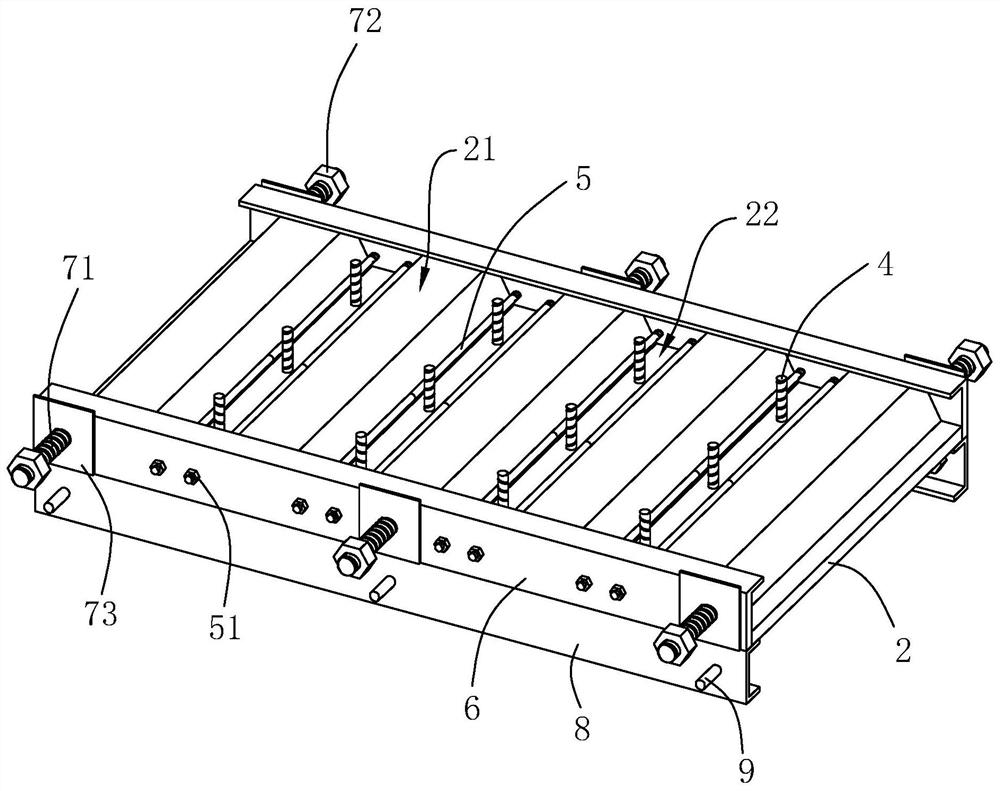

[0037] like figure 1 As shown, the steel plate 2 is provided with a fixing component, and the steel plate 2 and the construction column 3 are connected and fixed through the fixing component. Specifically, combine figure 2 , the fixing assembly includes a channel steel 8 welded on the peripheral side of the steel plate 2 and an anchor bolt 9 horizontally arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com